A non-return valve is a single-way valve that allows the fluid to flow only in one direction. The main importance of non-return valves is their working of allowing flow in the downstream direction and preventing the flow in the upstream direction. In this article, we will briefly learn about non-return valves, their types, functions, working, uses, and symbols.

Non-return valves are also known as NRVs. They are usually small, simple, and inexpensive. There are various types of non-return valves but the main function is the same. They are also known as one-way valves, check valves, clack valves, reflux valves, or retention valves. In the year 1907 Frank P Cotter developed the first simple model of a non-return valve.

Working Principle of a Non-Return Valve

Non-return valves use the mechanism to allow the medium only in the downstream direction. It has two openings: one inlet and the other outlet. A closing member (ball, clapper, or disc) separates the inlet and outlet, staying in between. When the fluid enters the non-return valve through the valve inlet, the fluid pressure keeps the closing member open. On the other hand, when the fluid attempts to flow in the backward direction from the outlet side to the inlet side, the closing member closes the entrance, which prevents the flow. Non-return valves work automatically without the need for control of any external element.

Applications of Non-Return Valves

Non-return valves find a range of applications in industrial and domestic sectors. Some of the uses of nonreturn valves are:

- Pump Discharge: A non-return valve known as a check valve is always installed at the pump discharge piping to prevent the backflow of the fluid.

- Transportation Fluid System: Transportation fluid systems use non-return valves in their pipelines to avoid the backward movement of the fluid.

- Nuclear Industry: Nitrogen feed systems, dump lines.

- Industrial Sampling systems

- Fluid Injection Systems of aircraft, spacecraft

- Laboratory Purification system

- Mixing chambers: A non-return valve is installed at each individual line to avoid gas mixing with the original source.

- Domestic Uses like Sprinkler systems, Home heating systems, inflatable mattresses and boats, drip irrigation systems, Rainwater harvesting systems, Hydraulic jacks, etc.

Types of Non-Return Valves

There are various types of nonreturn valves found for industrial applications. Their exact working mechanism may differ slightly, but the main function is similar. They are two-port valves. Since most non-return valves work automatically, they usually don’t have any handle or stem.

Depending on the exact working mechanism of the movable part that allows or blocks the fluid flow, non-return valves are classified as follows:

Swing check non-return valves:

In this type of non-return valve, the movable part is a disc. It swings on a hinge or trunnion to allow/block the fluid flow. A variety of different types of disc and seat designs are found to be used in different applications. In general, soft-seated swing check valves are more leak-tight.

Stop check non-return valves:

Stop check non-return valves possess an override control that stops the flow. It does not depend on the fluid pressure or flow direction.

Ball non-return valves:

The ball type of NRV features a movable spherical ball to block the flow. Sometimes they are spring-loaded.

Diaphragm NRVs:

This type of non-return valve uses a diaphragm (usually made of flexible rubber) that is controlled by fluid pressure.

Lift check non-return valves:

In a lift check NRV, a disc known as a lift operates to allow/block the flow. When the inlet pressure is high, the disc is lifted and the flow is allowed. When the pressure drops gravity force or outlet pressure lowers the disc and the flow is stopped. Normally used for high-pressure service.

In-line NRVs:

This type of non-return valve uses a spring and the flow is allowed when the upstream pressure exceeds the spring tension. Again when the pressure goes below the pressure to overcome spring tension the flow is blocked.

Folding disc non-return valves:

Mainly used for gaseous or low-pressure liquid service, this type of non-return valves are made in a wafer body pattern. They are also known as double-disc or split-disc check valves.

Tilting Disc NRVs:

Tilting disc types of non-return valves are suitable for turbulent, pulsing, or high-speed flows. The disk of this type of NRV floats within the flow and fluid runs on its top and bottom surfaces.

Foot Valves, Duckbill Valves, etc are also examples of non-return valves

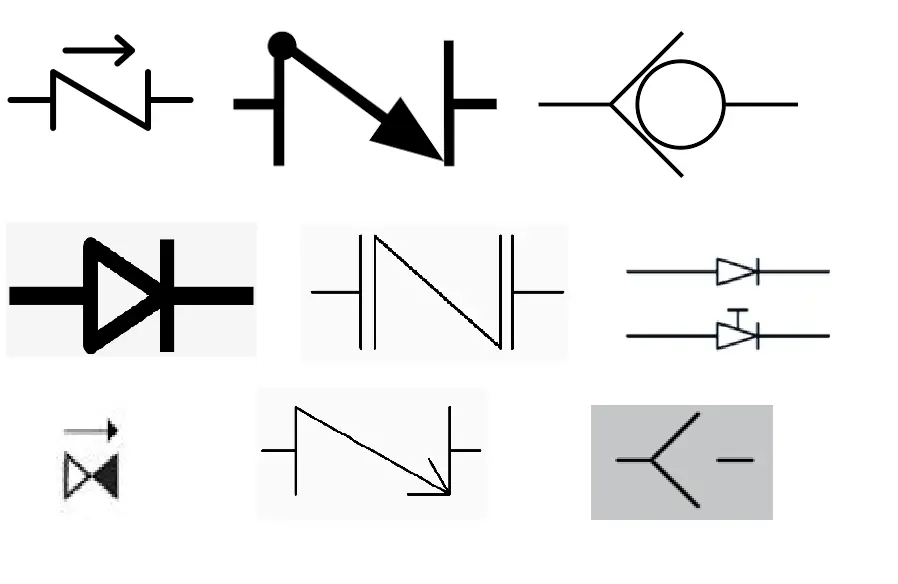

Non-Return Valve Symbol

The non-return valve symbols vary slightly from company to company. The common non-return valve symbols in P&IDs are provided below in Fig. 1

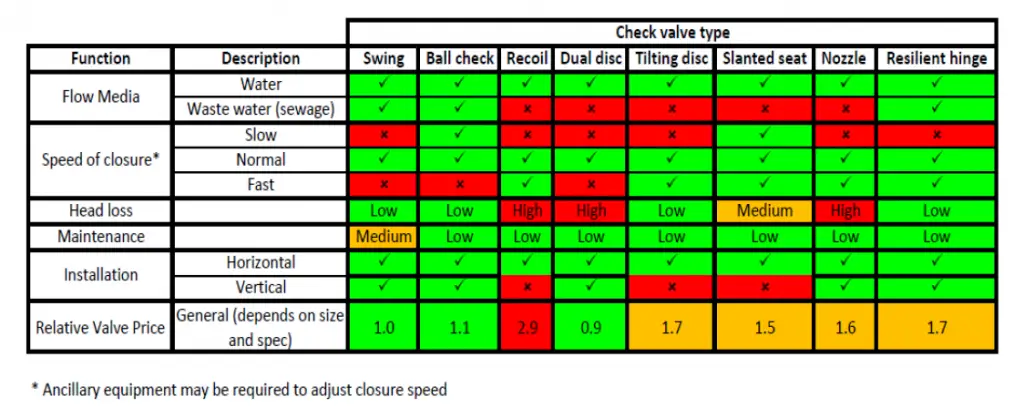

Selecting a Non-Return Valve

Selecting the proper type of NRV helps in smooth, trouble-free, low-maintenance, long-term operation. The selection of an NRV is influenced by various parameters like:

- Type of fluid to be carried.

- Location of the non-return valve

- Pressure and temperature of the flowing fluid.

- Hydraulic characteristics like minimum and maximum flow rates

- Closing time (Slow, normal, or fast-acting)

- Installation type; Vertical or Horizontal

- Cost

The table in Fig. 2 provides a sample guideline for selecting a proper type of NRV.

Functions of Non-Return Valves

The most important functions that a non-return valve performs are:

- It prevents damage to the upstream equipment due to reverse flow and

- Preventing reverse flow after shutdown (Water hammer/Surge)

Because of this, non-return valves are also known as safety-critical valves.

Non-Return Valve Maintenance

To ensure suitable maintenance of non-return valves, providing isolation of the check valve/NRV is always considered. In general, a gate or ball valve is used as an isolator. As a general engineering practice, the non-return valve or check valve is installed at a distance of 5D (D=Pipe/Pipeline OD) from the pump or any pipe fittings to avoid turbulence. The maintenance of non-return valves is carried out based on the manufacturer’s guidelines.

Difference between Non-Return Valve and Check Valve

Both the check valve and non-return valve perform the same duty of restricting and allowing flow only in one direction. Both are one-way valves. All valve types that act as unidirectional valves are non-return valves and the check valve is one of them. Most of the time check valves and non-return valves are used synonymously. There are various types of nonreturn valves such as foot valves, duckbill valves, etc. So, in layman’s language we can say:

All Check Valves are Non-Return Valves but All Non-Return Valves may not be Check Valves.

Can non-return valves (NRVs) be installed vertically?

Yes, some non-return valves can be installed in a vertical orientation. However, not all non-return valves can work in a vertical line. While installing an NRV, the manufacturer’s direction of the flow arrow must be studied and installed accordingly.

Difference between a reflux valve and a non-return valve

Both reflux valves and non-return valves are used to control the direction of fluid flow and prevent backflow in piping systems. They usually denote the same type of valve, and thus there is no difference between them.

Frequently Asked Questions

Let’s find the answers to some of the frequently asked questions that professionals wish to learn about non-return valves.

A non-return valve is a type of unidirectional valve that allows the flow of fluid in the downstream direction but prevents the backflow.

The non return valves are positioned where there is a requirement of preventing backflow. The placement of NRVs will be clearly marked in the P&ID drawings. A typical example is the pump discharge line. Additionally, the NRV is installed in a location such that it can be easily accessed and maintained.

The identification of a non-return valve is quite easy as the manufacturers place the flow direction on the valve body and mark an X mark at the end of the valve.

The main purpose of a non-return valve is to allow flow only in one direction and prevent the flow from the reverse direction.

Further Studies

For more details about the check valve types, components, working, and applications, follow the following article:

Please send full details or training on all type of valves .

Ball valves , butter valves , gate valves , check valves , IBR & Non IBR valves, etc.

Very nice, thank you!

Dear Sir,

I am in Hydro Electric Project, I am looking for Non Return Valve MTC or any Test Report. Can you please provide me the same in my WhatsApp No. ( +91 8794781763 )

Thanking You.

Can I use it in Solar Heater to stop backflow of water from the storage tank causing overflow !

Can anyone help us. What will happen in a swing check valve when high pressure acts reversely while low pressure established flow and the flap was full open.

Pump A was running 2Mpa with 100T/H flow, and Pump B was running in RC mode with pressure of 12Mpa. If Pump B discharge valve opened to parallel, what will happen to Pump A?

1. Will the flap or disc freezes the position for a moment or closes immediately?

2. Any video or articles can help us.

Hi, I’m looking for some advice please. I am looking at fitting a non return valve on a pipe approx 20 inches. The pipe takes water flow to a river and we need to stop the flow from coming back and flooding. Any help would be appreciated.

Hello, I hope you are well. I have a big house with a lot of piping inside. To pump hot water from the ground floor to the upper rooms causes a lot of heat loss due to the fact that the hot water must travel through each floor before reaching the destination. My question to you is: is it possible to install non-return valves(ball valve?) at each floor juncture points so that the water will use the shortest distance to the open faucet from the ground floor instead of traveling through each floor? I thank you in advance for your help.

I have a water softner. Due to less height of the OHT a 0.5 H.P. booster pump is fixed and was operating on Danfoss Pressure Switch and Pressure tank principle. But the motor was continuously running and hence I changed to flow switch type. Disconnected the pr.switch and pr.tank.

After fixing the flow switch when the tap was opened the pump starts running. But when the tap is closed the pump is not stopping and hence a NRV is fixed at the pump outlet line. Even then pump is not stopping. But if the ball valve at the pump outlet is closed then the pump stops immediately.

What type of NRV should be used for the application?