A Pig Signaller is a device used in the oil and gas industry to detect the passage of a pipeline inspection gauge, or “pig.” A pig is a tool used to clean, inspect or measure the inside of a pipeline. It is propelled through the pipeline by the flow of the fluid being transported. Pig Signallers are also known as pig detectors. Click here to know more about pipeline pigs.

The pig signaller is typically installed at a point along the pipeline where the pig is expected to pass, such as at the receiving end of a pipeline or at a valve station. The signaller detects the passage of the pig and sends a signal to the control room, indicating that the pig has passed and providing information on its location and speed.

The information provided by the pig signaller is important for pipeline operators to monitor the condition of the pipeline and to detect any issues such as corrosion, cracks, or other damage that may require maintenance or repair. Regular inspection and maintenance of pipelines using pigs and pig signallers can help ensure the safe and efficient transportation of oil and gas.

Types of Pig Signallers

There are several types of Pig Signallers used in the oil and gas industry. Here are some of the most common types:

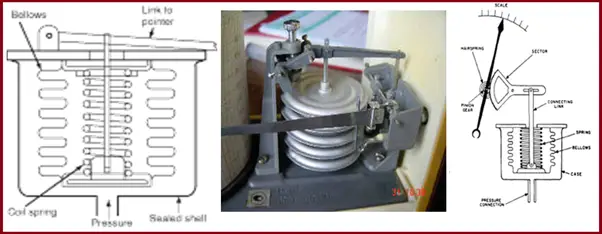

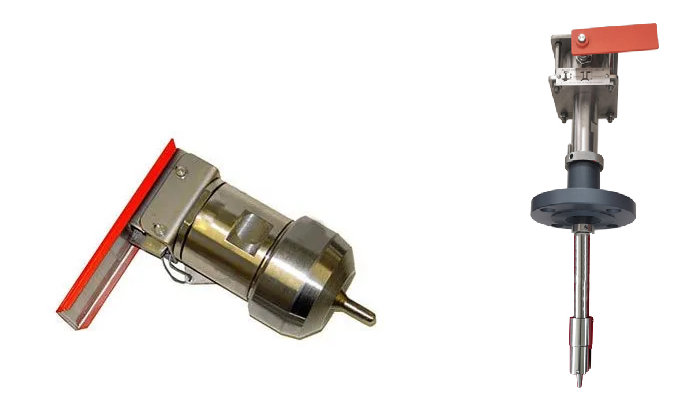

- Mechanical Pig Signaller: This type of signaller uses a mechanical trigger mechanism to detect the passage of the pig. The trigger is activated when the pig makes contact with a physical arm or lever, which sends a signal to the control room.

- Magnetic Pig Signaller: This type of signaller uses a magnetic field to detect the passage of the pig. The pig is equipped with a magnet, and when it passes by the signaller, the magnetic field is disrupted, triggering a signal to the control room.

- Acoustic Pig Signaller: This type of signaller uses sound waves to detect the passage of the pig. The pig is equipped with a transmitter that emits an acoustic signal, which is detected by the signaller and used to trigger a signal to the control room.

- Optical Pig Signaller: This type of signaller uses optical sensors to detect the passage of the pig. The pig is equipped with a reflective or fluorescent material, and when it passes by the signaller, the optical sensor detects the change in light, triggering a signal to the control room.

Each type of pig signaller has its advantages and disadvantages, depending on the specific application and environment in which it is used. Pipeline operators choose the type of pig signaller based on factors such as the type of pig being used, the size and material of the pipeline, and the operating conditions of the pipeline.

Intrusive vs Non-intrusive Pig Signallers

Pig signallers are also sometimes classified as Intrusive and Non-intrusive pig signallers.

An intrusive pig signaller is installed inside the pipeline and physically interacts with the pig as it passes through the pipeline. The intrusive pig signaller can be a mechanical switch, magnet, or sensor that triggers a signal when the pig comes into contact with it. The intrusive pig signaller may require a special fitting to be installed in the pipeline to allow for its insertion and removal.

A non-intrusive pig signaller, on the other hand, does not physically interact with the pig as it passes through the pipeline. Instead, it uses an external sensor or detector to detect the passage of the pig through the pipeline. This can be done using a variety of methods, including ultrasonic sensors, radio frequency identification (RFID) tags, or acoustic detectors.

The choice between intrusive and non-intrusive pig signallers depends on various factors, including the type of pig being used, the size and material of the pipeline, and the operating conditions. Non-intrusive pig signallers are typically easier to install and maintain, but may not be as accurate or reliable as intrusive pig signallers. Intrusive pig signallers, on the other hand, provide more accurate and reliable detection but require more complex installation procedures and may have a greater risk of damage to the pipeline.

The main differences between intrusive and non-intrusive pig signallers are:

- Installation: Intrusive pig signallers are installed inside the pipeline and require a fitting to be installed in the pipeline, whereas non-intrusive pig signallers are installed externally and do not require any modifications to the pipeline.

- Interaction with Pig: Intrusive pig signallers physically interact with the pig as it passes through the pipeline, while non-intrusive pig signallers do not.

- Accuracy: Intrusive pig signallers provide more accurate and reliable detection of the pig passing through the pipeline, while non-intrusive pig signallers may have a greater risk of false alarms or missed detections.

- Maintenance: Intrusive pig signallers require more maintenance and may have a greater risk of damage to the pipeline during installation or maintenance, while non-intrusive pig signallers are typically easier to maintain and less likely to cause damage.

- Cost: Intrusive pig signallers are typically more expensive to install and maintain, while non-intrusive pig signallers are typically less expensive.

The choice between intrusive and non-intrusive pig signallers depends on various factors, including the type of pig being used, the size and material of the pipeline, and the operating conditions. Non-intrusive pig signallers are typically easier to install and maintain, but may not be as accurate or reliable as intrusive pig signallers. Intrusive pig signallers, on the other hand, provide more accurate and reliable detection but require more complex installation procedures and may have a greater risk of damage to the pipeline.

Components of a Pig Signaller

The components of a pig signaller may vary depending on the type and manufacturer, but generally, a pig signaller consists of the following components:

- Housing: The housing is the outer casing of the pig signaller and protects the internal components from the environment.

- Trigger mechanism: The trigger mechanism is the component that detects the passage of the pig and sends a signal to the control room. The type of trigger mechanism varies depending on the type of pig signaller, as mentioned earlier.

- Signal transmitter: The signal transmitter sends a signal to the control room indicating the passage of the pig. The signal may be transmitted through wires, radio frequency, or other means depending on the specific pig signaller.

- Battery: The battery powers the pig signaller and is typically located inside the housing. The battery may be rechargeable or replaceable, depending on the type of pig signaller.

- Control circuitry: The control circuitry manages the signals and power supply of the pig signaller. It may include microprocessors, amplifiers, filters, and other electronic components.

- Mounting hardware: The mounting hardware is used to attach the pig signaller to the pipeline or valve station. The hardware may include clamps, brackets, or other mounting devices.

Pig signallers may also include additional features such as tamper-evident seals, remote monitoring capabilities, and alarms to alert operators of any issues or failures.

Materials for Pig Signallers

The common materials for pig signallers depend on the specific application, but generally, pig signallers are made of materials that can withstand the harsh environments and conditions in which they are used. Here are some of the most common materials used for pig signallers:

- Stainless Steel: Stainless steel is a common material for pig signallers because it is durable, corrosion-resistant, and can withstand high temperatures and pressures. It is also easy to clean and maintain.

- Aluminum: Aluminum is a lightweight material that is often used for pig signallers that need to be mounted on pipelines or valve stations. It is also resistant to corrosion and can withstand high temperatures.

- Plastic: Plastic is used for pig signallers that need to be lightweight, portable, and resistant to impact and harsh chemicals. It is also resistant to corrosion and can be easily molded into various shapes.

- Brass: Brass is a common material for pig signallers used in offshore environments because it is resistant to corrosion caused by saltwater exposure. It is also easy to machine and has good electrical conductivity.

- Carbon steel: Carbon steel is used for pig signallers that need to withstand high pressures and temperatures. It is also resistant to corrosion and is commonly used in oil and gas pipelines.

The choice of material for pig signallers depends on various factors such as the operating conditions, the type of pig being used, and the expected lifespan of the pig signaller.

Pig Signaller Purchase Specification

When specifying a pig signaller for purchasing, it’s important to consider the following factors:

- Type of Pig: The type of pig that will be used in the pipeline is an important factor in selecting the appropriate pig signaller. The size, shape, and material of the pig will determine the trigger mechanism and signal transmitter needed for the signaller.

- Trigger Mechanism: The trigger mechanism must be appropriate for the specific application and must be able to reliably detect the pig passing through the pipeline.

- Signal Transmission: The method of signal transmission must be appropriate for the application and the distance between the pig signaller and the control room.

- Pipeline Size and Material: The size and material of the pipeline will determine the size and strength of the mounting hardware needed for the pig signaller. It will also affect the type of signal transmitter needed for the signaller, as larger pipelines may require stronger and more powerful transmitters.

- Operating Conditions: The operating conditions of the pipeline, such as temperature, pressure, and corrosiveness of the fluid being transported, will also determine the materials and components needed for the pig signaller. For example, in harsh environments, such as offshore pipelines, pig signallers made of stainless steel or brass may be preferred due to their resistance to corrosion.

- Environmental Conditions: Environmental conditions, such as humidity, moisture, and exposure to UV radiation, should also be considered when selecting a pig signaller. For example, pig signallers used in outdoor environments may need to be weatherproof and have protective coatings to prevent damage from exposure to the elements.

- Compliance Requirements: The pig signaller may need to meet certain compliance requirements, such as safety regulations or industry standards, depending on the application and location. Be sure to check with the appropriate regulatory agencies and industry associations to ensure compliance.

When specifying a pig signaller for purchasing, it’s important to provide as much detail as possible about the pipeline and operating conditions to ensure that the correct pig signaller is selected. The manufacturer or supplier of the pig signaller can also provide guidance on the appropriate specifications

Pig Signaller Installation Guidelines

The installation guidelines for pig signallers may vary depending on the specific type and manufacturer of the pig signaller, but here are some general guidelines to follow:

- Select the appropriate location: The pig signaller should be installed in a location that is easily accessible for maintenance and monitoring, and should be located upstream of the pig launcher or receiver.

- Prepare the installation site: The installation site should be clean and dry, and any debris or obstructions should be removed. The pig signaller should be securely mounted using appropriate mounting hardware.

- Connect the signal transmission: The signal transmission should be connected according to the manufacturer’s instructions, which may include wiring, radio frequency or other communication methods.

- Connect the power source: The power source should be connected according to the manufacturer’s instructions, which may include batteries or external power sources.

- Test the pig signaller: Once installed, the pig signaller should be tested to ensure that it is working properly. This may include a functional test or a pressure test.

- Monitor the pig signaller: The pig signaller should be monitored regularly to ensure that it is functioning correctly and to detect any issues that may require maintenance.

It is important to follow the manufacturer’s specific installation guidelines when installing a pig signaller to ensure that it is installed correctly and operates as intended. It is also important to ensure that any applicable regulations and standards are met during the installation process.

Pig Signaller Manufacturers

There are several manufacturers of pig signallers, including:

- T.D. Williamson

- Pigs Unlimited International

- Enduro Pipeline Services

- Rosen Group

- NDT Global

- Pigtek Ltd.

- Baker Hughes

- MISTRAS Group

- Clock Spring

- Pipeline Engineering & Supply Co. Ltd.

It’s worth noting that this is not an exhaustive list, and there may be other manufacturers of pig signallers as well.

Price of a Pig Signaller

The price of pig signallers can vary widely depending on the type, model, and manufacturer. Intrusive pig signallers can be more expensive than non-intrusive pig signallers due to the additional installation and maintenance requirements.

Additionally, the cost of pig signallers can depend on the size and material of the pipeline, as well as the operating conditions. As a rough estimate, non-intrusive pig signallers can range from a few hundred dollars to several thousand dollars, while intrusive pig signallers can range from several thousand dollars to tens of thousands of dollars.

It’s important to note that these are rough estimates, and the actual cost of a pig signaller will depend on a variety of factors. It’s always best to consult with a reputable manufacturer or supplier to get an accurate price quote based on your specific needs and requirements.