What is Settle-out Pressure of a Centrifugal Compressor?

If a centrifugal compressor trips or stops for any kind of reason during the maximum pressure drop case in the system, the gas that is trapped between the upstream & downstream shutdown valves is equalized through the anti-surge line due to the opening of the anti-surge valve. This equalized pressure is referred to as the settle-out pressure of that compressor.

This settle-out pressure is used to establish the design pressure of the equipment & piping, mainly in the suction side of the centrifugal compressor.

Importance of Settle-out Pressure Calculation

- The settle-out pressure calculation of a centrifugal compressor is performed in various projects to determine the maximum suction side pressure, which is used in the determination of pipe class & equipment design pressure.

- As per API-521 recommendation, “Design pressure shall be a minimum of 1.05 times settle-out pressure at maximum pressure drop, calculated assuming the suction side is operated at normal operating pressure and discharge pressure is set to the maximum achievable.”

Hence, in designing suction equipment & piping, providing an adequate difference between operating & set pressure of the PSV is required for a shutdown contingency & to prevent flaring.

- Calculation for settle-out pressure is usually completed during the FEED stage of a project using preliminary estimation as described further, and is later reissued during the EPC stage with more precise piping isometrics and compressor curves. If the settle-out pressure is not calculated for the worst-case operating scenario or is not accounted for, the typical design upgrade from the FEED to the EPC phase will impact the project cost.

Methodology to Calculate Settle-out Pressure

A simple procedure to calculate the settle-out pressure is described below with some assumptions as follows:

Assumptions for calculation of settle-out pressure:

- The system is a closed loop, and no gas is escaping from the system; and all the gas/vapor behaves ideally.

- The rate of closure of suction & discharge shutdown valves, in addition to the discharge check valve, is neglected.

- The piping is considered to be adiabatic, & no heat escapes from the equipment or piping.

- The time delay between the fully closed & fully open positions of the anti-surge valve & check valve is not considered.

- If the system contains any liquid, the liquid will absorb the energy (in the form of latent heat of vaporization) from the system to flash, and thus the overall vapor temperature will be reduced, which will in turn result into the decrement of calculated settle-out pressure. Hence, for a conservative approach, the liquid volume is not considered.

Now, let’s proceed towards the CALCULATION procedure.

Loop Identification:

Firstly, recognize the section where the isobar will prevail once the system is in a settled-out condition. The system volume & confined mass need to be determined, and lumped mass and enthalpy should be distributed in the settle-out situation to calculate the final pressure.

Estimation of Volume:

The volume of each section is to be calculated at each pressure level. To calculate the volume, PDS of each piece of equipment and 3D model/isometric for the associated line are preferred. If not available, the following rule of thumb can be used:

- Volume occupied by Catalyst/Absorbent inside Reactor = 60% of Vessel Volume.

- Volume of vapor in a separator = 40% of Separator Volume.

- Volume of vapor in a KO Drum = 60% of KO Drum Volume.Volume of vapors inside piping, heaters, exchangers in phase service = 50% of total volume of piping, heater tubes & exchanger tubes of shell volume as the case may be.

- The compressor’s internal volume normally would not be used.

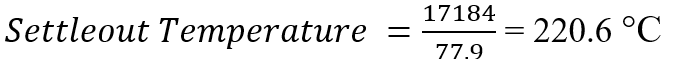

Settle-out Temperature:

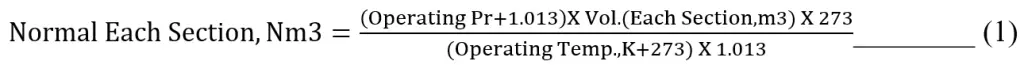

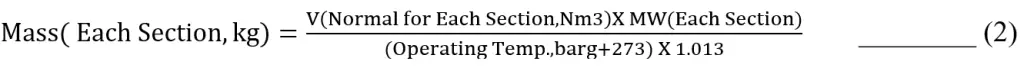

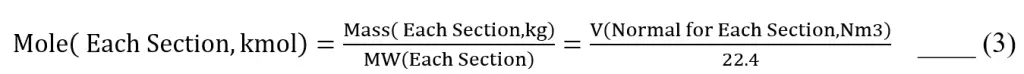

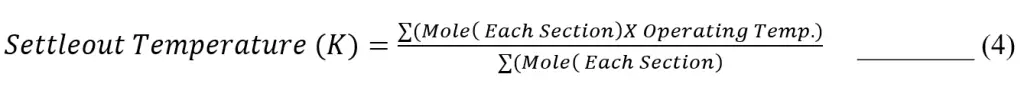

It should be calculated based on the volume of each isothermal section, since it will change at more locations than pressure. The procedure to calculate are as follows-

- Calculate the normal volume for each section.

- Then all gas masses in the system at different operating pressure & temperature are added to estimate the total system mass & finally, equalized temperature.

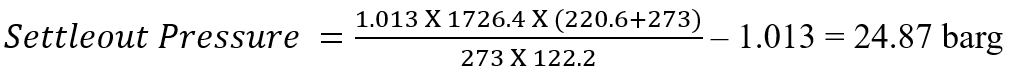

Settle-out Pressure:

For Single-Stage Compressor

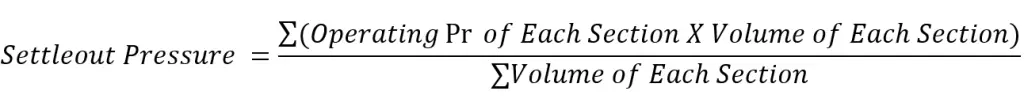

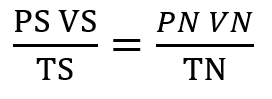

Now, after calculating the Total Actual Volume, Settle-out temperature etc., finally the settle-out pressure is calculated as –

where,

- PS = Settle-out Pressure (barg),

- VS = Total Actual Volume (m³),

- TS= Settle-out Temperature (K),

- PN = Atmospheric Pressure (barg),

- VN = Total Normal Volume (Nm³),

- TN = 273 K.

Case Study (Single Stage Compressor)

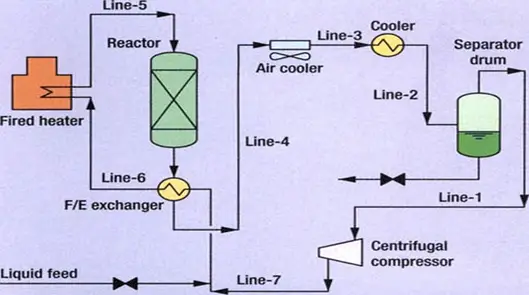

A sample reaction loop (Fig-1) is considered for calculating the settle-out pressure. Reactor liquid feed, after combination with the recycled gas feed, is preheated by the reactor feed/effluent exchanger and further heated by the fired heater up to the reaction temperature and supplied to the reactor. The reactor effluent gas is cooled by a feed/effluent exchanger and two coolers. The cooled effluent enters the product separator and separated gas is recycled to the reactor by the recycle gas compressor.

With all the operating conditions and using Equations (1) to (5), the settle-out of this system is estimated below:

| Component | Volume of Each section (m3) | Pressure of Each Section (barg) | Temperature (°C) | Normal Volume of Each Section (Nm3) | Mole (Kmol) = (Normal Volume/ 22.4) | Temperature X Kmol (°C) |

| Line-1 | 1.8 | 23.2 | 45 | 35.4 | 1.6 | 72.0 |

| Separator | 17 | 23.2 | 45 | 334.3 | 15.1 | 680.3 |

| Line-2 | 1 | 23.2 | 45 | 19.7 | 0.9 | 40 |

| Cooler | 5 | 23.2 | 45 | 98.3 | 4.4 | 200.1 |

| Line-3 | 1.2 | 23.2 | 65 | 22.5 | 1.0 | 66.1 |

| Air Cooler | 2 | 23.5 | 65 | 38.3 | 1.7 | 112.5 |

| Line-4 | 5 | 24 | 110 | 84.5 | 3.8 | 420.1 |

| F/E Hex. | 16 | 24 | 110 | 278.2 | 12.6 | 1383.7 |

| Reactor | 42 | 24.7 | 450 | 400.9 | 18.1 | 8159.4 |

| Line-5 | 3.5 | 25.6 | 450 | 33.4 | 1.5 | 680.0 |

| Fire Heater | 4.2 | 25.6 | 410 | 47.2 | 2.1 | 876.1 |

| Line-6 | 3 | 28.5 | 410 | 33.7 | 1.5 | 625.8 |

| F/E Hex. | 16 | 30.3 | 410 | 191.3 | 8.7 | 3548.3 |

| Line-7 | 4.5 | 30.3 | 65 | 108.7 | 4.9 | 319.6 |

| ∑ = | 122.2 (VS) | 1726.4 (VN) | 77.9 | 17184.0 |

For Multi-Stage Compressor

Incase of multistage compressor, intercoolers across the stages ensure isothermal conditions. So, temperature variations across the stages can be considered almost constant. Hence, for calculating settle-out pressure doesn’t require settle-out temperature parameter. The empirical equation to calculate Settle-out Pressure will reduce to simply as below-