What is a Solenoid Valve?

A solenoid valve is an electromechanical valve that operates using an in-built actuator in the form of an electrical coil and a plunger. An electrical signal controls the opening and closing of the solenoid valve. There are two modes in which solenoid valves are produced. They are normally open and normally closed. The solenoid (electrical coil) is operated using an AC or DC. DC supply is provided through a battery, generator, or rectifier. Whereas an AC supply is usually taken from AC mains voltage, through a transformer.

What is a Solenoid valve used for?

A solenoid valve is used to open, close, mix, or divert liquid and gaseous media in an application. Solenoid valves find wide applications in industrial as well as domestic sectors. The use of solenoid valves ranges from the control of standard process valves to the control of specific valves like overpressure protection systems and emergency stop valves, as well as fluid control in applications like fire system valves. The major advantage of a solenoid valve compared to traditional valves is the very fast response time. Some of the common applications include:

- Solenoid valves in refrigeration systems reverse the refrigerant flow that cools during summer and heats during winter.

- Solenoid valves are used in compressors during the starting phase to discharge the compressor in order to reduce the torque on the engine.

- Solenoid valves are used in irrigation systems for automatic control purposes.

- Solenoid valves in washing machines and dishwashers control the water flow as per requirement.

- Air pressure in air conditioning systems is controlled by solenoid valves.

- Automatic locking systems for door locks use solenoid valves.

- Car washes and Industrial cleaning equipment use solenoid valves to control the water, soap, or chemical flow.

- The inflow and outflow of water in water tanks are often controlled using solenoid valves.

- The pressure, flow, and fluid direction in controlled by solenoid valves in dental and various medical equipment.

Working of a Solenoid Valve

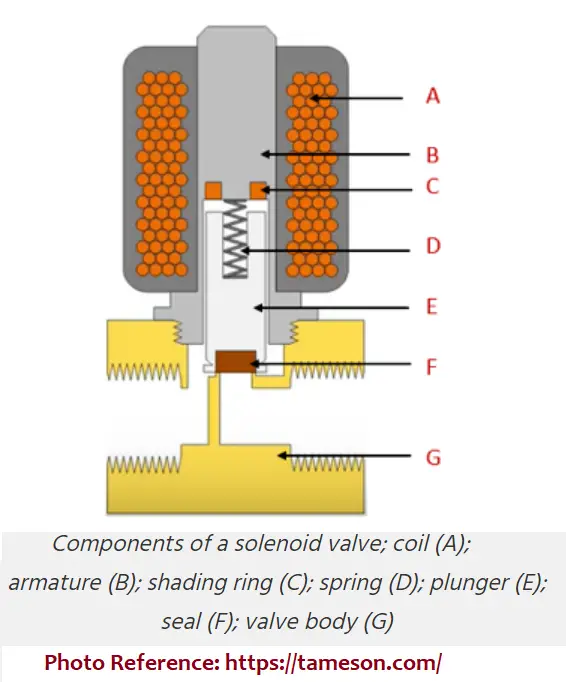

A solenoid valve has two main components: a solenoid and a valve body (G). The following figure (Fig. 1) shows the typical components of a solenoid valve. The electromagnetically inductive coil (A) around an iron core at the center is known as the plunger (E). At rest, it will be either normally open (NO) or normally closed (NC). During the de-energized phase, a normally open valve remains open while a normally closed valve remains closed. When current flows through the solenoid coil, it is energized and creates a magnetic field that creates a magnetic attraction with the plunger. Because of this, the plunger moves by overcoming the spring (D) force. For a normally closed solenoid valve, the plunger is lifted and the seal (F) opens the orifice allowing the media to flow through the valve. While for a normally open solenoid valve, the plunger moves downward and the seal (F) blocks the orifice which stops the media from flowing through the valve. The shading ring as denoted by (C) in Fig. 1 prevents vibration and humming in AC coils.

Solenoid valves are used to control the flow of liquids and gases automatically. In the most varied types of plants and equipment, they are being used to an increasing degree. A variety of different designs are available to suit a particular application.

Types of Solenoid Valves

Depending on the number of pipe connections Solenoid valves are classified into three groups.

- Two-Way Solenoid Valves and

- Three-Way solenoid Valves

- Four-Way Solenoid Valves

Two-Way Solenoid Valves

As the name suggests, a two-way solenoid valve has one inlet and one outlet piping connection. They can be categorized into the following two types.

- Normally closed construction: The valve is closed when de-energized and open when energized.

- Normally open construction: This type of Solenoid valve is closed when energized and open when de-energized.

Three-way Solenoid valves

Three-way solenoid valves have three pipe connections and two orifices. When one orifice is open the other is closed and vice versa. Three-way solenoid valves are commonly used alternatively to apply pressure to and exhaust pressure from a diaphragm valve or single-acting cylinder. They operate in the following three modes:

Normally closed construction: When the valve is de-energized, the pressure port is closed and the exhaust port is connected to the cylinder port. With the valve energized, the pressure port is connected to the cylinder port and the exhaust port is closed.

Normally open construction: The pressure port is connected to the cylinder port when the valve is de-energized. But when the valve is energized the pressure port is closed and the cylinder port is connected to the exhaust port.

Universal construction: This type allows the valve to be connected in either the normally closed or normally open position. In addition, the valve may be connected to select one or two ports or to divert flow from one port to another.

Four Way Solenoid valves

Four-way solenoid valves are used to operate double-acting cylinders. These types of solenoid valves have four or five pipe connections; One pressure, two-cylinder, and one or two exhausts. In one valve position, the pressure is connected to the cylinder port; the other is connected to the exhaust. In the other valve position, pressure and exhaust are reversed at the cylinder connections.

Depending on the functions of the solenoid valves, they are classified as

- General-purpose solenoid valves

- Safety shut-off valves and

- Process-control valves

General-purpose solenoid valves: This type of solenoid valve is either a normally open or normally closed valve used for controlling the flow of a fluid. However, these valves do not act as safety valves.

Safety shut-off valve: This is normally a closed valve of the “on” or “off” type that actuates using a safety control device for preventing unsafe fluid delivery. A multiple-port valve can work as a safety shut-off valve with respect to its normally closed port.

Process-control valve: These type of solenoid valves are approved to control flammable gases but does not reliably work as a safety shut-off valve.

Depending on the working methodology, solenoid valves are classified into four groups as follows:

- Direct-acting solenoid valves

- Pilot-operated solenoid valves

- Pressure-operated solenoid valves

- Air-operated solenoid valves

Direct-acting solenoid valves

In a direct-acting solenoid valve, the core directly opens the orifice of a normally closed valve or closes the orifice of a normally open valve. The orifice size and fluid pressure decide the force required to open the valves. With an increase in the orifice size, the force required also increases.

Pilot-operated solenoid valves

This type of solenoid valve is equipped with a pilot and a smaller orifice. They utilize the line pressure for operation. When the solenoid is energized, the pilot orifice is opened and it immediately releases the pressure from the top of the valve piston or diaphragm to the outlet of the valve. This causes an unbalanced pressure which forces the line pressure to lift the piston of the diaphragm off the main orifice and open the valve.

When the solenoid is de-energized, the pilot orifice is closed and full line pressure is applied to the top of the piston or diaphragm through the orifice, producing a sealing force for tight closure. There are two common types of construction:

- floating diaphragm or piston

- hung-type diaphragm or piston.

Pressure-operated solenoid valve

These types of solenoid valves are usually diaphragm or piston-operated valves. They are normally equipped with a 3-way or 4-way solenoid pilot that controls the opening or closing of the main valve using operating pressure.

Air-operated solenoid valves

This solenoid valve type has two basic functional units.

- an operator with a piston or diaphragm assembly that develops a force upon pressurization.

- a valve with an orifice in which a plug or disc is positioned to allow or stop the flow.

A piston is normally used for pneumatic operation whereas low and instrument air-pressure range operators typically use a diaphragm.

Solenoid Valve Enclosures

Depending on the application of the solenoid valves, the solenoid coils are enclosed using various types of enclosures. Their main purpose is to protect the coil from dust, indirect splashing, water, etc.

Selection of Solenoid Valves

The selection of a specific type of solenoid valve is not easy. A number of physical and operating factors are required to be decided when selecting a solenoid valve for a particular application. Some of these parameters are:

Pressure:

There are various pressure terms that should be known prior to solenoid valve selection. They are:

- The maximum operating pressure differential that the electrical solenoid has to overcome for opening or closing the valve must be known during the selection process.

- Similarly, the minimum pressure drop that will exist across the valve during flowing is also required.

- Safe static pressure at which the valve will be subjected during normal service.

- Proof pressure is usually considered 5 times the safe working pressure.

Temperature:

Similar to the pressure mentioned above, the following temperatures should be known:

- Minimum, Maximum, and Normal ambient temperatures

- Maximum fluid temperature

Viscosity:

The viscosity of the flowing fluid at the operating temperature is also an important parameter during solenoid valve selection.

Response time:

The response time of a valve is the time-lapse for the solenoid valve to go from the open to a closed position or vice versa. Depending on the valve size, the response time of a solenoid valve varies. It is also dependent on the type of electrical supply, fluids handled, temperature, pressure, and pressure drop.

Type of solenoid valve:

Depending on the application requirement, the necessity of a 2-way or 3-way solenoid valve has to be determined. Decide beforehand if the specific application requires a direct, indirect, or semi-direct operated solenoid valve.

Solenoid valve housing material:

Based on the chemical properties and temperature of the flowing media and the environment, the valve housing material is determined. Common solenoid valve housing materials are Brass, Stainless steel, PVC, and polyamide.

Solenoid Valve Sizing

Sizing and selection of the appropriate type of solenoid valve are highly essential as both undersized and oversized valves have various undesirable effects. The basic factors that are considered during solenoid valve sizing are

- Minimum and maximum flow to be controlled.

- Minimum and maximum pressure differential across the solenoid valve

- Specific gravity, temperature, and viscosity of the fluid handled.

- Inlet and outlet pipe diameter.

- Supply voltage.

The optimal size of a solenoid valve is decided by determining the flow rate, which allows for determining the flow factor (kv). The flow factor indicates the volume of water at room temperature that flows through the solenoid valve with a pressure drop of 1 bar for one minute.

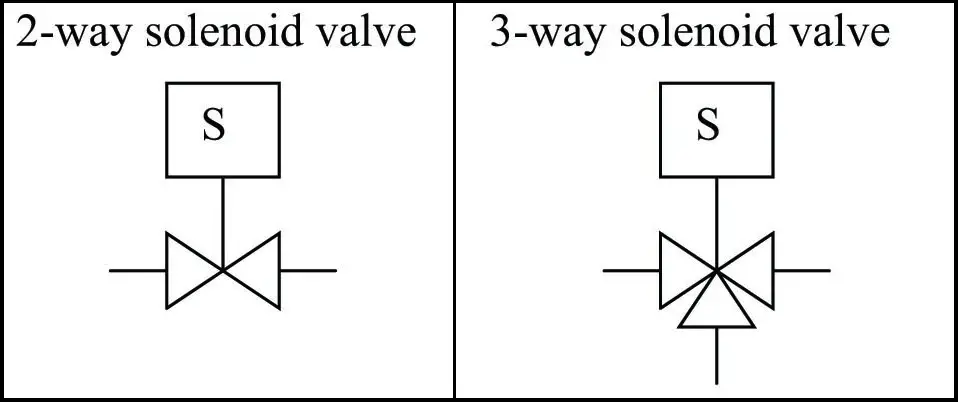

Solenoid Valve Symbol

Similar to other valves, There is a specific symbol for solenoid valves. Fig. 2 below shows the Solenoid valve symbol representation.

Hello Anup

I find your blogs informative. (only read two) I am one of the guys that fix the things that engineers design

and lots of times we growl severely, The places that bolts are placed so that 15 different tools are involved instead of four. When Engineers share this kind of information it helps out Thank You. A few technical specs or equations that explain watts in solenoids, has to do with motive power, like how many watts pull how many pounds.

hope this helps Pops

Great post! Solenoid valves are essential in many industrial and domestic applications, such as controlling the flow of gases and liquids in systems like refrigeration, air conditioning, and irrigation. It’s amazing how these small devices can manage pressure, flow, and even direction in so many critical systems. If you’re looking for high-quality solenoid valves for various applications, be sure to check out Auto2mation.