What is a Surge Relief Valve?

A surge relief valve is a specially designed valve that protects piping and pipeline systems from pressure surge events caused by rapid valve closure, emergency shut-down, or pumps trip situations. As they are inexpensive and can be installed at any location of interest, Surge relief valves are reliably used in the Oil & Gas, Chemical, Petrochemical, Power, Marine, and Nuclear Industries. Surge relief valves can be used in all systems requiring some kind of pressure relief to avoid personnel, equipment, or asset loss due to failure from an overpressure situation.

Surge Relief Valve Function

The main function of a surge relief valve is to quickly open during a pressure surge incident and relieve the high-pressure fluid to any safe outlet. In the normal scenario, the valve remains in a closed position by the compression of a spring. When the pipeline pressure becomes more than the surge relief valve set pressure, the valve disc quickly opens to release the overpressure. Again, when the system pressure subsides and reduces below set pressure, the valve automatically closes.

So, to protect the system from dangerous surge conditions, surge relief valves must have the following characteristics:

- Quick Opening Speed to rapidly relieve the surge pressure. Open fully in a very short time.

- Non-Slam Capability so that it does not cause pressure rise during valve closure.

- Sufficient capacity to relieve the entire high-pressure fluid.

Types of Surge Relief Valves

Two types of Surge relief valves are widely used in process industries:

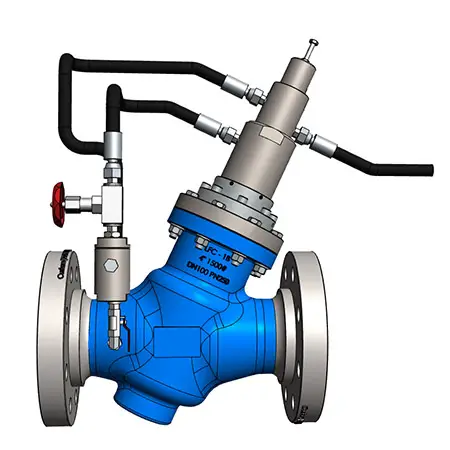

- Pilot-operated surge relief valve, and

- Gas-loaded surge relief valve (Normally Nitrogen is used)

The main features of pilot-operated surge relief valves are:

- Suitable for low-viscosity refined products

- Completely self-contained/self-acting

- Relatively slow response

- Stable operation

- Disc action is controlled by a mechanical pilot valve.

- No external energy sources.

Pilot-Operated Surge Relief Valves are normally used for pump trip cases and installed at the inlet or outlet of the pump station.

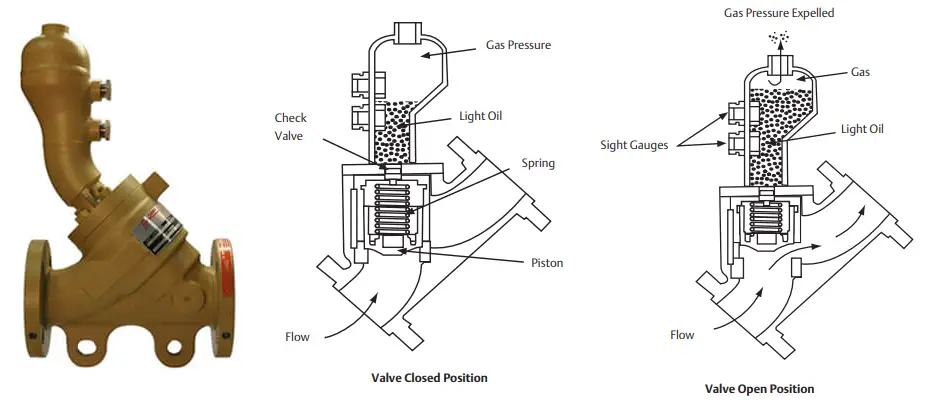

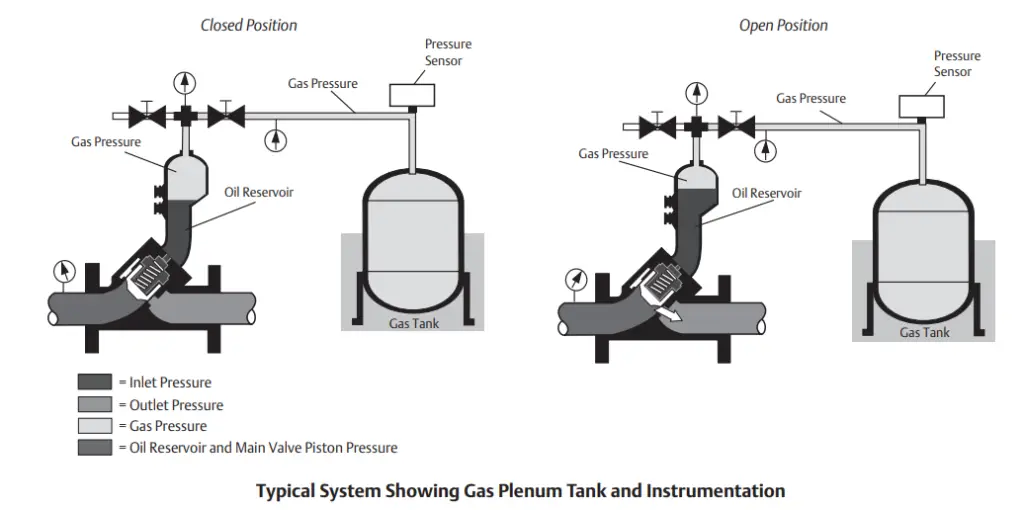

On the other hand, gas-loaded relief valves are used in transportation pipeline systems. The main features of gas-loaded (nitrogen-loaded) pressure relief valves are:

- Suitable for all types of petroleum products, including high-viscosity or dirty products

- Exceptionally fast response

- For more efficient operating conditions can maintain a minimum back pressure

The system relief pressure and the amount of fluid the valve must pass when it relieves will govern the required pressure of the gas loading system. Accordingly, the surge relief valve size will be decided. Such systems offer flexibility in design according to what is desired, including extremely rapid opening, as illustrated in Fig. 3 below. It follows that the higher the differential pressure the faster the valve will open.

Surge Relief Valve Sizing

The sizing of the surge relief valve depends on various factors like

- Potential for pressure rise

- system capacity

- location of the surge relief valve

- other safety and control measures in the system

- pipeline length, and thickness.

- Maximum fluid velocity and maximum allowable pressure.

In normal practice, surge relief valves are normally selected following various charts and nomograms.

Selection of Surge Relief Valve

To safeguard the complete piping/pipeline system from surge pressure, the right surge pressure relief valve selection is highly important. Selection is dependent on various factors like:

- Valve Response Time: Gas-loaded relief valve is faster as compared to pilot-operated ones.

- Valve Co-efficient: It is recommended that the required Cv should not exceed 85% of the selected valve size actual Cv. Note that, the Cv of a Valve varies by size, type, and manufacturer.

- Excess pressure above the set point to reach the required flow rate

- Valve characteristic control curve

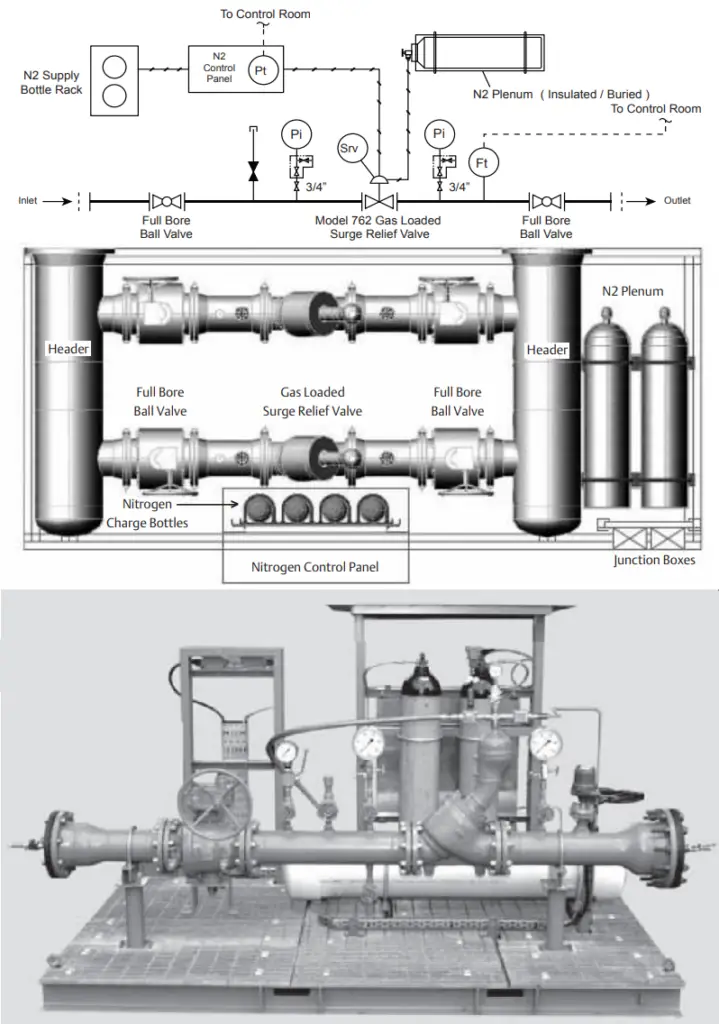

Skid-Based Surge Relief Valve System

In recent times, skid-based surge relief systems provide a complete solution for surge events. Such skids comprise of properly sized surge relief valve with the nitrogen system integrated into the skid and inlet & outlet manifolds with isolation valves upstream and downstream of the surge relief valves. Fig. 4 below shows such a typical surge relief valve skid.

Clear explanations

Good morning,

I’m a Representative for Daniel Measurement and Control (the supplier of the Gas Loaded Valve you show on your site). Our company, working with Daniel, has made some new advances to this technology. These advances allow for better response and control of the valve. We have presented our technical paper on this subject at shows like ISHM and the International Pipeline Exhibition in Calgary, Canada. I would love to share this info with you so your page can be as up to date as possible. Please let me know if this is something that interests you.

Kind regards,

Kristen Konopa