Through bolting is a fundamental technique used in various industries to create strong and secure connections between components. Whether in construction, engineering, or manufacturing Through Bolting plays a crucial role in maintaining structural integrity and safety. This article will delve into the concept of through bolting, its applications, the necessary tools and materials, and best practices to ensure successful and reliable connections. Toward the end, we will learn some basic differences between Anchor bolts and Through Bolts.

What is a Through Bolt?

A through bolt, also known as a through-bolt or a through-bolted fastener, refers to a type of fastener used to create a secure connection by passing a bolt completely through two or more components or layers and securing it with a nut on the opposite side. The bolt typically has a threaded shank that allows for the attachment of a nut, which, when tightened, creates a clamping force that holds the components together.

Through bolts are designed to provide strong and reliable connections, often used in applications where high strength and stability are required. They are commonly made of materials such as steel, stainless steel, or titanium, chosen based on the specific application’s requirements.

The primary characteristic that sets through bolts apart from other fasteners is their ability to pass completely through the components being joined. This feature enables the through bolt to provide greater shear and tensile strength compared to other fastening methods that rely on surface contact or limited penetration.

Through bolts find extensive use in various industries and applications. In construction, they are employed to connect structural members like steel beams, columns, and plates, ensuring the stability and integrity of the structure. In machinery and equipment assembly, through-bolts are used to secure heavy components together, providing strength and reliability to the overall system. They are also commonly used in automotive applications, securing critical components like engine blocks, transmission assemblies, and suspension systems.

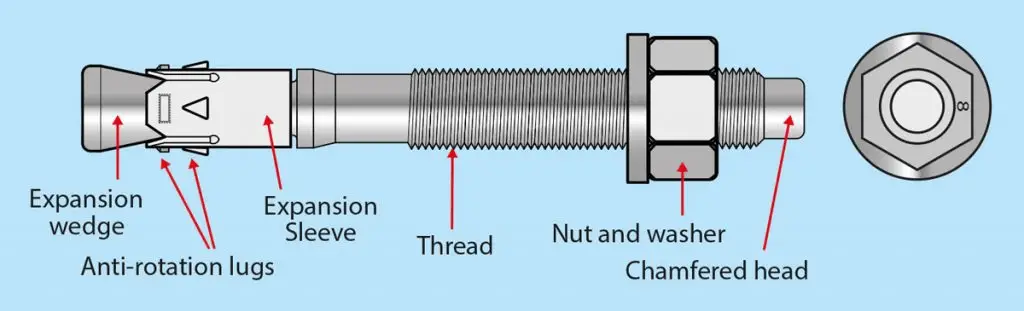

By utilizing through bolts, engineers and manufacturers can create robust connections that can withstand high loads, vibrations, and forces. These fasteners play a vital role in maintaining the structural integrity, safety, and longevity of numerous systems and structures across different industries. Fig. 1 shows a typical image of a through-bolt showing its component parts.

What is Through Bolting?

Through bolting is a method of fastening two or more components together by passing a bolt completely through them and securing it with a nut on the opposite side. The bolt typically has a threaded shank, allowing the nut to be tightened and create a clamping force that holds the components in place.

Applications of Through Bolting

Construction:

Through bolting is extensively used in the construction industry for connecting structural members such as steel beams, columns, and plates. It provides strength and stability to the overall structure, especially in critical load-bearing areas.

Machinery and Equipment:

Through bolting is crucial for assembling heavy machinery and equipment, ensuring that all components are securely fastened together. It is commonly employed in industries like manufacturing, mining, and power generation.

Automotive:

In the automotive sector, through-bolting is used to secure critical components such as engine blocks, transmission assemblies, and suspension systems. It helps withstand the vibrations and forces encountered during vehicle operation.

Tools and Materials Required

To carry out through-bolting effectively, you will need the following tools and materials:

- Bolts: Select through-bolts based on the application’s requirements, considering factors such as length, diameter, material, and strength. Common materials include steel, stainless steel, and titanium.

- Nuts: Use nuts that match the bolt specifications. It’s essential to ensure compatibility between the bolt and nut, considering thread type (e.g., coarse or fine) and diameter.

- Washers: Washers distribute the clamping force evenly and protect the surfaces of the connected components. Use flat washers, lock washers, or specialized washers depending on the application.

- Wrenches: Adjustable wrenches or socket wrenches are needed to tighten and loosen the nuts. Ensure that the wrench size matches the bolt and nut dimensions.

- Torque Wrench: For critical applications, a torque wrench is essential to achieve accurate and consistent bolt tightening. It helps prevent over-tightening or under-tightening, ensuring optimal performance.

Through Bolting Best Practices

- Proper Alignment: Ensure that the holes in the components are accurately aligned before attempting to insert the bolt. Misalignment can lead to difficulties during installation or compromised strength.

- Hole Preparation: Clean the holes and remove any debris or contaminants that may hinder the bolt’s insertion or affect the clamping force. Holes should be large enough to allow easy passage of the bolt without binding.

- Lubrication: Apply an appropriate lubricant to the bolt threads to minimize friction during tightening. This facilitates smooth installation and prevents thread damage.

- Torque Specifications: Refer to the manufacturer’s specifications for recommended torque values. Under or over-tightening can compromise the connection’s strength or cause bolt failure, so ensure accurate torque application.

- Inspection and Maintenance: Periodically inspect through-bolted connections to ensure they remain secure. Check for signs of loosening, corrosion, or other issues that may compromise the integrity of the connection.

Difference between Anchor Bolts and Through-Bolts

Here’s a tabular comparison highlighting the differences between a through bolt and an anchor bolt:

| Through Bolt | Anchor Bolt |

|---|---|

| Passes completely through the components being joined | Embedded partially in a substrate (such as concrete) |

| Requires access to both sides of the components for installation | Requires access to only one side for installation |

| Typically consists of a bolt with a threaded shank and a nut on the opposite side | Comprises a threaded rod or bolt, an anchor body, and an expansion mechanism (such as a nut, washer, or wedge) |

| Provides a clamping force by tightening the nut on the opposite side | Provides anchorage by expanding or engaging with the substrate |

| Used to connect components together in various applications, providing strength and stability | Primarily used for securing objects to a concrete or masonry base |

| Commonly employed in construction, machinery assembly, automotive, and general fastening applications | Widely used in structural and civil engineering, including building foundations, concrete slabs, and structural columns |

| Offers high shear and tensile strength due to its complete penetration through the components | Provides excellent pullout resistance and load-bearing capacity through its interaction with the substrate |

| Can be easily disassembled and reassembled, allowing for component replacement or adjustment | Generally intended for permanent installations and may require more effort to remove or relocate |

| Requires accurate alignment of holes in the components being joined | Requires accurate drilling and placement of anchor holes in the substrate |

| Relies on the clamping force generated by tightening the nut for its strength and stability | Relies on the mechanical interlocking or expansion within the substrate for its strength and stability |

It’s important to note that while through-bolts and anchor bolts have distinct characteristics and applications, they both serve critical roles in creating secure connections and maintaining the integrity of various structures and systems.

Conclusion

Through bolting is a vital technique for creating secure connections in a wide range of industries. Understanding the proper procedures, selecting the appropriate tools and materials, and following best practices is key to achieving reliable and robust connections. By employing through-bolting correctly, you can ensure the structural integrity and safety of various applications, providing peace of mind and long-lasting performance.