Steel is an alloy containing Iron and Carbon as the primary elements. Various other alloying elements are added to it to achieve some desired properties in Steel. It is a prime commodity and finds extensive uses worldwide in buildings, tools, cars, weapons, infrastructure, ships, trains, machines, electrical appliances, etc. Steel can be classified depending on various factors or characteristics. In the following paragraphs, we will explore different types of steel in detail.

Grades of Steel

The widely used engineering material Steel, comes with several distinct grades with different chemical compositions. There are a number of ways by which steel can be classified. However, the most widely popular classification is based on their chemical composition as provided by the American Iron & Steel Institute (AISI).

Types of Steel based on Chemical Composition | Four Types of Steel

Depending on the chemical composition, according to the AISI, the following four basic types of steel are distinctly grouped. They are:

- Carbon Steel

- Alloy Steel

- Stainless Steel

- Tool Steel

1. Carbon Steel:

This type of steel accounts for around 90% of total steel production. Most of the steel we find all around is made from this grade of steel because of its strong and durable nature. Carbon Steel contains less than 2% carbon without any purposeful alloying additions. Depending on the amount of carbon present, Carbon Steel is categorized into three main classes. They are

- Low Carbon Steel or Mild Steel: This grade of steel is the least expensive type and is quite common in use. Low Carbon Steel or Mild Steel contains up to 0.3% carbon. It possesses very good formability and finds wide structural application.

- Medium Carbon Steel: This type of carbon steel contains 0.31% to 0.6% carbon and 0.31% to 1.60% magnesium. Medium carbon steels are stronger than mild steel, but with an increase in carbon content, the formability reduces. They can be found in applications like gears, railroad tracks, cranks, machinery parts, pressure structures, etc. The properties of medium carbon steel lie in between mild steel and high carbon steel.

- High Carbon Steel: High carbon steel grades contain more than 0.6% carbon and 0.31 % to 0.9% magnesium. This type of steel has the maximum strength and hardness with the lowest ductility and formability. High carbon steels find their application in bars, plates, spring steel, knives, taps, wire drawing dies, cutters, etc.

2. Alloy Steel:

Alloy steels contain one or more alloying elements (nickel, manganese, titanium, copper, silicon, chromium, molybdenum, cobalt, tungsten, vanadium, and aluminum) in varying proportions. Purposeful addition of these alloying elements is done to manipulate the steel’s properties as required for different applications. Specific properties like hardenability, corrosion resistance, strength, formability, weldability, or ductility can be improved on alloy steels based on applications. Alloy steels are widely available, costlier than common carbon steels, and find their applications in pipelines, transformers, power generators, auto parts, and electric motors. Depending upon the combination of alloying additions, different grades of alloy steels are available. The most widely used alloy steel types are provided below:

- Tungsten Steel for high heat resistance

- Nickel Steel for toughness.

- Manganese Steel for excellent wear resistance and work hardening

- Vanadium Steel for high shock and vibration resistance.

- Chromium Steel for corrosion and wear resistance.

- Chromium-Vanadium Steel for high tensile strength along with ductility.

- Silicon Steel for producing permanent magnets.

- Molybdenum Steel for good corrosion resistance, weldability, and toughness.

- Cobalt Steel for tremendous corrosion resistance, wear resistance, high-temperature strength, and magnetic properties.

- Aluminum Steel for low weight along with high strength.

3. Stainless Steel:

Stainless steels are made of 10 to 20% chromium as the main alloying element. This grade of steel is highly popular due to its appearance and high corrosion resistance. Stainless steel with more than 11% chromium is approximately 200 times more resistant to corrosion as compared to carbon steel. They are expensive and widely used in the form of plates, sheets, bars, tubes, and wires. Depending on the crystalline structure and composition of stainless steel, this type of steel is sub-divided into five categories as provided below:

Austenitic Stainless Steel:

Austenitic stainless steels are non-magnetic and non-heat-treatable and generally contain 18% chromium, 8% nickel, and less than 0.8% carbon. They form the largest portion of the global stainless steel market and are widely used in food processing equipment, kitchen utensils, and piping.

Ferritic Stainless Steel:

Ferritic steels contain trace amounts of nickel, 12-17% of chromium, less than 0.1% carbon, and molybdenum, aluminum, or titanium in small quantities. They are tough, strong, and magnetic and can be further strengthened by cold working.

Martensitic Stainless Steel:

Martensitic stainless steels contain 11-17% chromium, less than 0.4% nickel, and up to 1.2% carbon. These magnetic and heat-treatable steels are used in knives and cutting tools, as well as dental and surgical equipment.

Duplex Stainless Steels:

This type of stainless contains a combination of ferritic and austenitic structures in their crystal structure. DSS materials are weldable, corrosion-resistant, and possess high strength. I have already published more details about duplex stainless steel. Kindly click here to access that article.

Precipitation Hardening Stainless Steel:

This type of stainless steel is comprised of 17% chromium and 4% nickel. Additionally, small amounts of aluminum, copper, and niobium are also added. As the name suggests, this group of stainless steels is a variety of hardened stainless steels and finds application in engine components and nuclear waste casks.

4. Tool Steel:

Tool Steels are a variety of abrasion-resistant, high-hardness steel types that make them suitable for use as manufacturing tools. Tool steels are available in the form of round, square, or flat bars and are used to make hammers, dies, molds, cutting tools, etc. Common alloying elements of tool steels are molybdenum, vanadium, tungsten, and cobalt, which makes them heat-resistant, durable, and strong. Six grades of tool steels are widely used in industries. They are

- Air-hardening tool steels

- Water-hardening

- High Speed

- Hot-working

- Shock-resisting types

- Oil-hardening

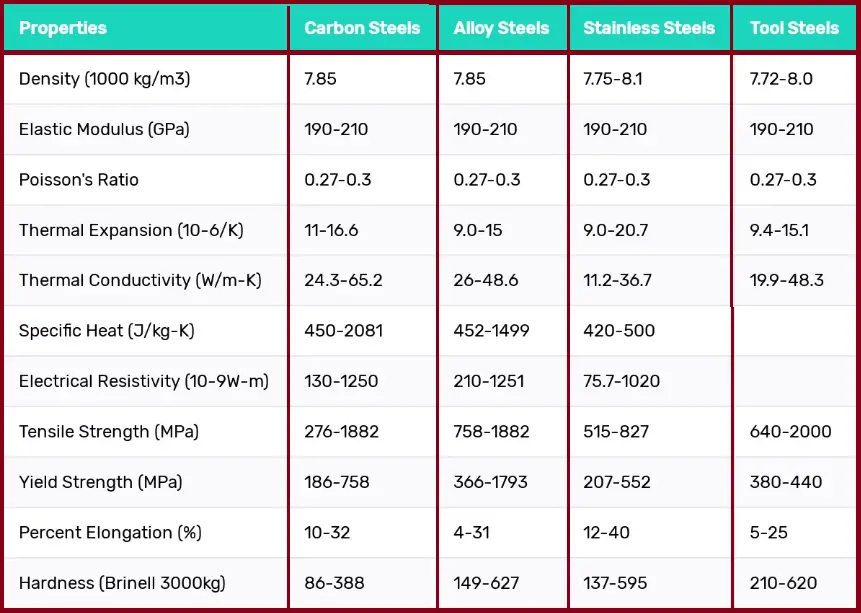

The following image in Fig. 1 provides some properties on the Grades of Steel Chart.

Steel Numbering Systems

Two major numbering systems are widely followed in the steel industries. They are:

- Steel numbering system by AISI and

- Steel numbering system by SAE (Society of Automotive Engineers)

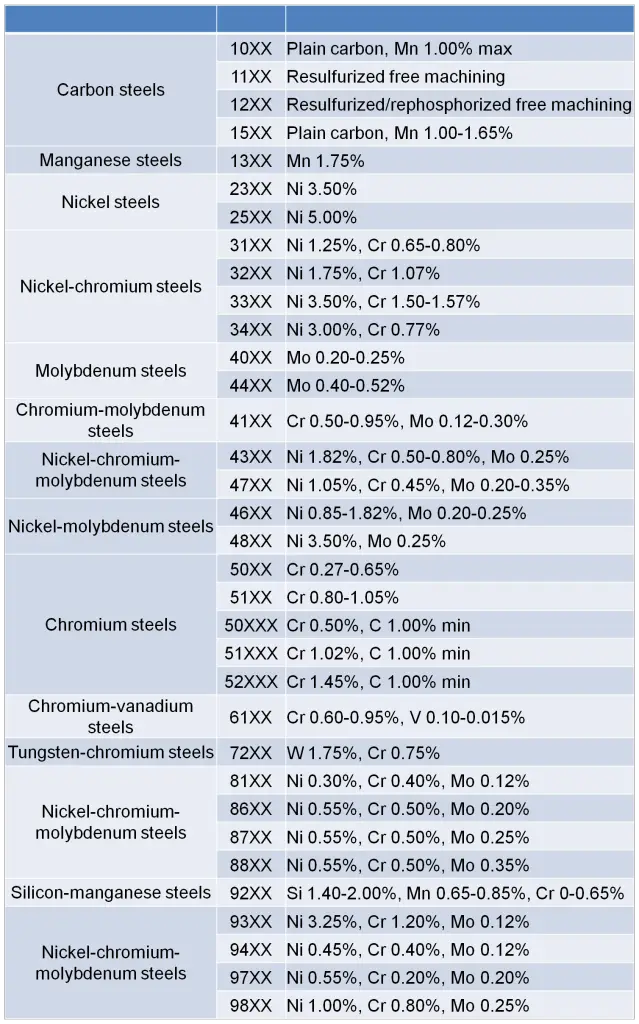

Both AISI and SAE steel numbering systems consist of a four-digit designation system. However, note that there are certain types of alloy steels designated by five digits. The first digit explains the type of steel. If it is “1” then it indicates Carbon steel. So all carbon steel in this numbering system starts with 1. Similarly, the meaning of the first digit is provided below:

- “2” denotes Nickel steels.

- “3” denotes Nickel-chromium steels.

- “4” denotes Molybdenum steels.

- “5” denotes Chromium steels.

- “6” denotes Chromium-vanadium steels.

- “7” denotes Tungsten-chromium steels.

- “8” denotes Nickel-chromium-molybdenum steels, and

- “9” denotes Silicon-manganese steels and various other grades

The second digit usually indicates the concentration of the major alloying element. The last two digits in the steel numbering system refer to the amount of carbon present in that steel grade. For example, SAE 1010 refers to mild steel containing 0.1% Carbon. Similarly, SAE 5130 refers to chromium steel with 1% chromium and 0.3% carbon.

The image in Fig. 2 clearly explains the AISI/SAE Steel numbering system philosophy in detail.

Types of Steels based on Steel Smelting (De-oxidation) Process

Depending on the degree of oxidation three types of steel are available. They are:

- Rimmed Steel: Low-cost, uneven-quality steels that are incompletely deoxidized.

- Killed Steel: Completely deoxidized steel with high quality and cost.

- Semi-Killed Steel: Partly deoxidized steel having quality and cost in between rimmed and killed steel.

Steel Types by Manufacturing Method

Depending on the process used to manufacture steel products, they are grouped as follows:

- Steel parts made by cold rolling are known as Cold Rolled Steel.

- Steel components produced by hot-rolling are known as Hot-Rolled Steel.

- Cold Drawn Steel: products made by a cold drawing operation.

- Cast Steel: Complex shapes made by the casting process

- Forged Steel: products made by various forging methods.

Types of Steel Depending on Application

Based on the intended application Steel can be classified into various groups as listed below:

- Structural Steel used in structural applications.

- Tool Steels used for making tools.

- Marine Steel used in seawater applications.

- Boiler Steel to make parts of steam services.

- Bridge Steel

- Spring Steel

- Pressure Vessel Steel, etc

Other Steel Types

Various other types of steel classification can be made as listed below:

- Based on the steel production method: continuous cast steel, electric furnace steel, etc.

- Based on microstructure: ferritic steel, pearlitic steel, martensitic steel, etc.

- Based on heat treatment: annealed steel, quenched steel, tempered steel, etc.

- Depending on the quality nomenclature: commercial quality steel, drawing quality steel, pressure vessel quality steel, etc.

I AM A RETD. MECHANICAL ENGINEER. IT MUST HELP ,SPECIALLY, IN THE FIELD OF DESIGNING WORKS.

Dear Anup

Thank you so much for your invaluable information. I absorbed a lot. I am a novice trader, I need to increase my knowledge of the field in order to be able to buy and sell. Please provide me with more info simplistic info if possible.

Sincerely

Mostafa

Very comprehensive!~Congrats!

I would appreciate it if you could explain plastication, eutectite and eutechtoid points. Also explain Cast iron.

Thank you in advance.

well informed, thank you so much.

In carbon steel section, there will be Manganese instead of Magnesium.