In the world of industrial metallurgy, stainless steel and alloy steel are two commonly used materials with distinct properties and applications. While both share similarities, they differ significantly in composition, characteristics, and usage. This article aims to shed light on the differences between stainless steel and alloy steel, providing readers with a comprehensive understanding of these two versatile materials.

What is Stainless Steel?

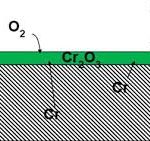

Stainless steel is a type of steel alloy that is widely used in various industries due to its exceptional corrosion resistance and durability. It is composed primarily of iron, with a minimum of 10.5% chromium content by mass. The addition of chromium forms a thin, invisible, and protective oxide layer on the surface of the steel, known as a passive film. This passive film is what gives stainless steel its remarkable resistance to corrosion, staining, and rusting.

Apart from chromium, stainless steel can also contain other alloying elements such as nickel, molybdenum, and titanium. These additional elements further enhance the material’s properties, including its strength, toughness, and resistance to high temperatures. The specific composition of stainless steel can vary depending on the desired characteristics and the intended application.

Stainless steel is known for its versatility and is utilized in a wide range of industries. In the construction sector, it is commonly used for structural components, architectural features, roofing, and cladding. In the food and beverage industry, stainless steel is the preferred material for kitchen appliances, cutlery, cookware, sinks, and food processing equipment due to its hygienic properties and ease of cleaning. It is also extensively used in the medical field for surgical instruments, medical equipment, and storage tanks.

The automotive industry relies on stainless steel for exhaust systems, car trim, and decorative features due to its aesthetic appeal and resistance to corrosion caused by road salts and environmental factors. Moreover, stainless steel is widely used in the chemical and petrochemical industries for tanks, pipes, valves, and other equipment that handle corrosive substances. It is also utilized in marine applications, such as boat fittings and shipbuilding, where it can withstand exposure to saltwater and harsh marine environments.

One of the key advantages of stainless steel is its excellent formability, which allows it to be shaped into various products and structures through processes such as rolling, bending, and welding. It is a durable and low-maintenance material that retains its appearance and structural integrity even under challenging conditions.

Overall, stainless steel’s corrosion resistance, hygienic properties, strength, and versatility make it a highly sought-after material in numerous industries, where durability and reliability are paramount.

So from the above discussion, it is quite clear that stainless steel is also a specific form of alloy steel.

What is Alloy Steel?

Alloy steel is a type of steel that is made by adding various alloying elements to iron during the steelmaking process. These alloying elements can include manganese, silicon, copper, nickel, chromium, molybdenum, vanadium, tungsten, and others. The addition of these elements imparts specific properties to the steel, such as increased strength, hardness, toughness, and resistance to wear, heat, and corrosion.

The composition of alloy steel can vary widely depending on the desired characteristics and the intended application. The percentage of alloying elements added to the iron base typically ranges from 1% to 50% or more. This wide range of alloying elements and compositions allows for a broad spectrum of alloy steel grades with varying properties.

Alloy steel is known for its exceptional strength and durability, making it suitable for applications that require high-performance materials. It is commonly used in industries such as automotive, aerospace, construction, oil and gas, machinery, and tooling.

In the automotive industry, alloy steel is utilized for manufacturing various components like gears, axles, shafts, and engine parts. The high strength and toughness of alloy steel allow these parts to withstand heavy loads and provide better performance and longevity.

In the aerospace sector, alloy steel is used for structural components of aircraft, including landing gears, wings, and engine parts. The strength-to-weight ratio of alloy steel makes it valuable in this industry, as it allows for the construction of lightweight yet strong and reliable parts.

The construction industry utilizes alloy steel for structural applications that require high strength and resistance to impact and wear. Reinforcing bars, structural beams, and high-strength fasteners are commonly made from alloy steel.

In the oil and gas industry, alloy steel is utilized in the construction of pipelines, pressure vessels, and drilling equipment. These components must withstand extreme temperatures, pressures, and corrosive environments, making alloy steel an ideal choice due to its excellent mechanical and corrosion-resistant properties.

Alloy steel is also widely used in the production of machinery, tools, and heavy equipment. Its toughness and hardness enable the manufacturing of durable and reliable components that can withstand the rigors of industrial applications.

One of the advantages of alloy steel is its versatility, as it can be engineered to meet specific requirements by adjusting the alloying elements and their concentrations. This allows manufacturers to tailor the material’s properties to match the demands of various applications.

In summary, alloy steel is a steel variant that incorporates alloying elements to enhance its mechanical properties. Its high strength, hardness, toughness, and resistance to wear, heat, and corrosion make it suitable for a wide range of demanding applications across different industries.

Differences between Stainless Steel and Alloy Steel

The differences between stainless steel and alloy steel can be understood clearly if we find the differences with respect to some parameters. In the following section, we will compare both alloys with respect to certain important factors.

Stainless Steel vs Alloy Steel with respect to Composition:

Stainless Steel:

Stainless steel is primarily composed of iron and a minimum of 10.5% chromium. This chromium content forms a protective oxide layer on the surface, known as a passive film, which makes stainless steel highly resistant to corrosion, staining, and rusting. Additional alloying elements such as nickel, molybdenum, and titanium may also be added to enhance specific properties, including strength and resistance to high temperatures.

Alloy Steel:

Unlike stainless steel, alloy steel is a broad term that encompasses a range of steels containing various alloying elements. These elements can include manganese, silicon, copper, nickel, chromium, molybdenum, vanadium, and more. Alloy steel is known for its exceptional mechanical properties, including high strength, hardness, toughness, and wear resistance. The addition of different alloys enables manufacturers to tailor alloy steel to specific applications.

Differences between Alloy Steel and Stainless Steel with respect to Characteristics:

Stainless Steel:

Stainless steel is widely recognized for its remarkable corrosion resistance, making it an ideal choice for applications in environments prone to moisture, chemicals, or extreme temperatures. It maintains its appearance and structural integrity even in demanding conditions. Stainless steel is also renowned for its hygienic properties, making it suitable for applications in the food and medical industries. Moreover, stainless steel offers excellent formability, weldability, and low maintenance requirements.

Alloy Steel:

Alloy steel boasts exceptional strength and hardness, making it suitable for high-stress applications such as structural components, automotive parts, machinery, and tools. Its alloying elements enhance specific properties, allowing manufacturers to achieve desired characteristics such as increased toughness, improved heat resistance, or enhanced wear resistance. Alloy steel can be engineered to withstand extreme temperatures and pressures, making it indispensable in the oil and gas, aerospace, and power generation industries.

Differences as per Applications:

Stainless Steel:

Stainless steel finds extensive use in a wide array of applications across industries. Its corrosion resistance makes it a popular choice for kitchen appliances, cutlery, cookware, and sinks. It is also widely used in construction for structural components, roofing, and cladding. The medical and pharmaceutical sectors rely on stainless steel for surgical instruments, medical equipment, and storage tanks due to its hygienic properties. Additionally, the automotive, chemical, and marine industries benefit from stainless steel’s durability and resistance to harsh environments.

Alloy Steel:

The exceptional strength and durability of alloy steel make it invaluable in various applications. It is commonly employed in the manufacturing of automotive parts, such as gears, axles, and engine components. The construction industry utilizes alloy steel for structural beams, reinforcing bars, and high-strength fasteners. Oil and gas pipelines, pressure vessels, and drilling equipment also heavily rely on alloy steel due to its ability to withstand extreme conditions. Additionally, alloy steel is widely used in the production of tools, machinery, and heavy equipment.

Other major differences between alloy steel and stainless steel are produced below in a tabular format.

| Parameters | Stainless Steel | Alloy Steel |

| Chemical Composition | Primarily iron and at least 10.5% chromium, may contain other alloying elements | Iron with various alloying elements such as manganese, silicon, copper, nickel, chromium, molybdenum, vanadium, etc. |

| Tensile Strength | Varies based on grade. The usual range of tensile strength is 515-827 Mpa. So tensile strength of alloy steel is comparatively lower than alloy steel. | Varies based on alloying elements and heat treatment. Generally, alloy steels have higher tensile strength as compared to stainless steel. The usual range is 758 to 1882 Mpa. |

| Hardness | The general hardness range for stainless steel is 150HB to 300HB | The usual hardness range for alloy steels is 200HB to 600HB. So, alloy steels are harder than stainless steels. |

| Ductility | Generally good | In general, alloy steels possess higher ductility than alloy steel materials. |

| Impact Resistance | Lower impact resistance due to low hardness. | Higher impact resistance due to higher hardness. |

| Fatigue Strength | Varies based on grade. Duplex Stainless steels have higher fatigue strength as compared to alloy steels but usual stainless steel has lower fatigue strength than alloy steel. | in general alloy steel have higher fatigue strength than stainless steel. |

| Corrosion Resistance | High | Varies based on alloying elements and coatings but is usually lower than stainless steel materials. |

| Durability | Excellent | Varies based on alloying elements and heat treatment |

| Weldability | Generally good | Alloy steel has lower weldability than stainless steel elements. |

| Machinability | Generally good | Alloy steels usually have better machinability than stainless steel. |

| Formability | Good | Varies based on alloying elements and heat treatment |

| Availability | Widely available | Wide range of options available |

| Versatility | Versatile applications in various industries | Wide range of applications across industries |

| Initial Cost | Generally moderate to high but varies depending on the stainless steel grade. The usual range is $800 to $2500 per ton. | Generally low to moderate. The approximate cost is $600 to $800 per ton. |

| Lifecycle Cost | Often lower due to its durability and corrosion resistance | Can vary based on maintenance and exposure to corrosive environments |

| Applications | Construction, automotive, food processing, medical, etc. | Automotive, aerospace, oil and gas, machinery, tooling, etc. |

| Maintenance | Generally low maintenance requirements | Can vary depending on the specific alloy and application |

| Advantages | Excellent corrosion resistance, hygienic, versatile | High strength, toughness, and wear resistance, tailored properties |

| Disadvantages | Higher initial cost, may lack the same strength as some alloy steels | Susceptible to corrosion in certain environments, may require protective coatings or treatments |

Conclusion

While stainless steel and alloy steel share the commonality of being steel alloys, their compositions, properties, and applications differ significantly. Stainless steel’s corrosion resistance and hygienic properties make it suitable for applications requiring durability and aesthetic appeal. On the other hand, alloy steel’s diverse alloying elements provide enhanced mechanical properties, enabling it to withstand high-stress environments. Understanding the distinctions between these materials is crucial in selecting the appropriate material for specific applications, ensuring optimal performance and longevity.