Wind analysis is performed based on the Client/ITB requirement. Wind load is an occasional load that normally occurs less than 20% of plant operating time. There are two methods for wind analysis-Static and Dynamic. In this article, I will explain the static method of wind analysis using Caesar II of Hexagon PPM (COADE Inc) following the Pressure Vs Elevation Profile.

Criteria for the selection of lines for Wind Analysis:

Criteria should be mentioned in the ITB document. As a guideline, the following can be followed after verification from the client:

- Lines with outside diameter 10” and larger (including insulation) running on 10 m and above.

- Steam / Flare header on the pipe rack.

- Other lines are considered important as per the stress engineer’s decision.

However, if lines are covered by some shelter or other structures then wind analysis can be ignored for those lines.

Data Required for Wind Analysis

For wind analysis, you must have the following data from the client.

- Wind shape factor: Normally for pipe elements, the data varies from 0.6-0.8. Check in the ITB document what value it says to use.

- Pressure Vs Elevation Profile: Sometimes the client provides this profile directly and sometimes provides equations and data to calculate the profile. A typical wind profile will be shown in the diagram while explaining the steps required while analyzing using Caesar II.

- Elevation of the line under analysis. If HPP (Highest Pavement Point) elevation is other than 0 you have to reduce HPP from line global elevation to get the actual elevation.

What to check in the Analysis

As per code B 31.3, we have to check code compliance of the calculated occasional stress (Sustained +Wind). The allowable stress for wind analysis is 1.33 times the Sh values. However, sometimes the client requires checking the nozzle loading in Operating+ Wind cases (W+T+P+Win) for static equipment. Normally the client does not require wind load checking for rotating equipment.

Steps for Static Analysis in Caesar II

Most of the steps are mentioned in the attached images. All are self-explanatory. However, if you face any problem in understanding please reply in the comments section.

- Model the piping system under analysis from piping isometric drawings.

- Enter the elevation of the first node in global coordinates.

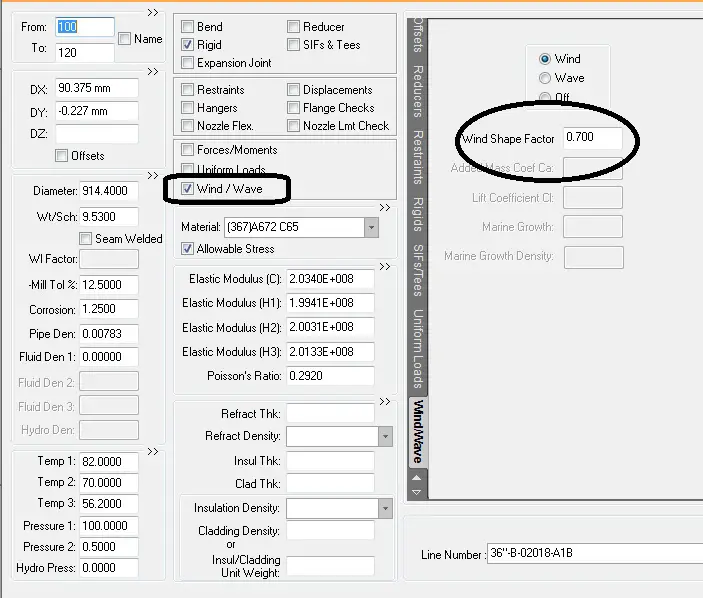

- Click on the Wind/Wave checkbox on Caesar II Spreadsheet and mention the wind shape factor as shown in Fig. 1

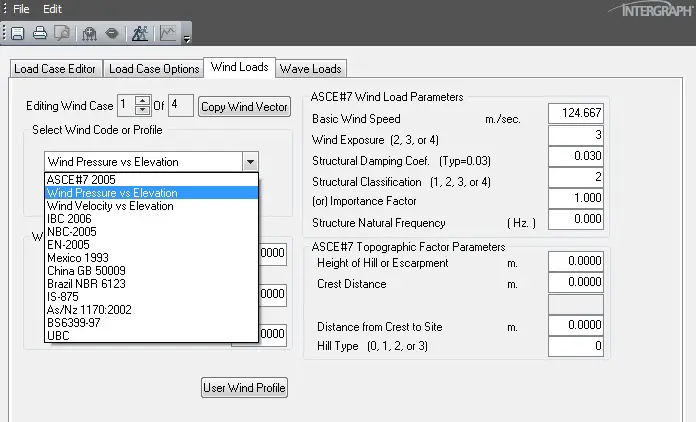

- Now run the analysis and go to the load case editor and select Pressure Vs Elevation as shown in Fig. 2

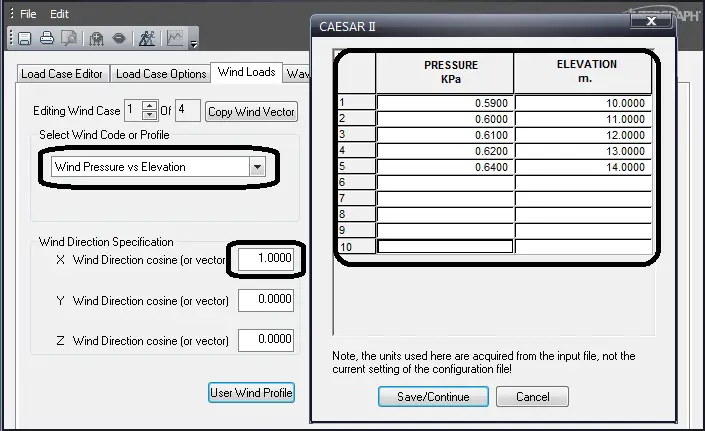

- In the next step enter the pressure vs elevation profile in-consistent unit and enter wind direction cosines as shown in Fig. 3. Normally wind analysis is performed considering wind flow from North, South, East, and West direction. Accordingly, Enter +1 or -1 in X or Z direction. Wind analysis is generally not considered in a vertical direction.

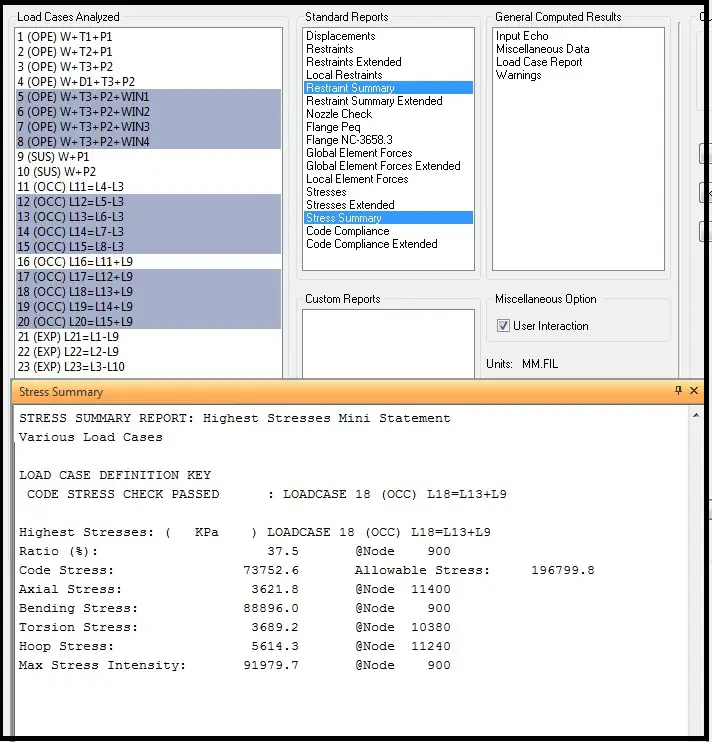

- Refer to Fig. 4 and prepare the highlighted load cases additionally for wind analysis. Load cases for L17 to L20 are for code compliance checking and load cases from L5 to L8 are for support and Nozzle load checking.

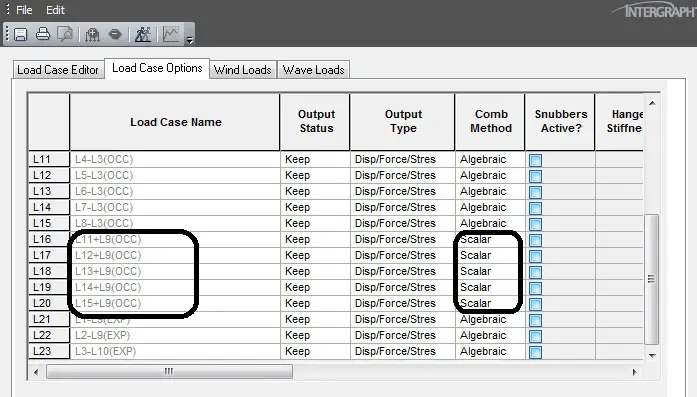

- Refer to Fig 5 and make the combination method scalar or absolute for the shown load cases.

- In the final stage run the analysis and check the results. If failing makes suitable adjustments to qualify the same.

Few more resources for you…

Static Seismic Analysis in Caesar II

Stress Analysis Basics

Stress Analysis using Caesar II

Stress Analysis using Start-Prof

Piping Design and Layout Basics

Piping Materials Basics

I appreciate your explanation, and I believe your approach is common industry practice. However, in most cases, I don’t believe the piping engineer has enough information in order to perform a reasonable wind (or seismic) analysis using piping stress analysis. Why? For one thing, wind shielding. Structural engineers know the placement of structural frame elements, equipment, piping, cable trays, etc. which can have a big effect on the distribution of wind load depending on the placement of these items. Pipes shield wind load from other pipes. So does equipment and structure. Piping engineers typically ignore shielding and that’s incorrect, although unfortunately it’s standard industry practice in my experience. Second, piping engineers do not have easy access to structural displacements from wind (or seismic) loads which can impose significant imposed displacements at pipe support points and anchor points. Seismic analysis is even more questionable since pipe stress models rarely/never include mass of structure, equipment and cable trays, or consider flexibility of the structure.

How will you fix pressure and elevation at different level.

Hi

How to calculate the pressure values at different level, is there any formula used or any procedure followed for that.

Certain project specification will ask for API RP 2A, or ASCE#7 for calculating the Wind vs. Velocity profile.

Is there a possibility to assign wind load to multiple nodes at once in Caesar II? Thank you!

Thanks for your contribution. It is very helpful and convenient each time I come back and visit this site, time by time.