Definition of Cold Spring

Cold Spring is the process of intentional deformation (usually accomplished by cutting short or long the pipe runs between two anchors) of piping during assembly to produce a desired initial displacement and stress. Cold Spring is the intentional stressing and elastic deformation of the piping system during the election cycle to permit the system to attain more favorable reactions and stresses in the operating condition.

Why Cold Spring?

Cold Springs can help to

- Reduce the hot stresses to mitigate the creep damage.

- Reduce the hot reaction forces on connecting equipment.

- Control the movement space.

Actual use of Cold Spring

- The general belief is that the additional creep damage caused by the initial thermal expansion stress (due to cold pull) is insignificant if the total expansion stress range is checked within the allowable limit. Also, the code does not allow us to take advantage of cold springs in reducing stresses.

- The control of the movement space is secondary.

- Thus the real gain of cold spring has become the reduction of the hot reaction on the connected equipment.

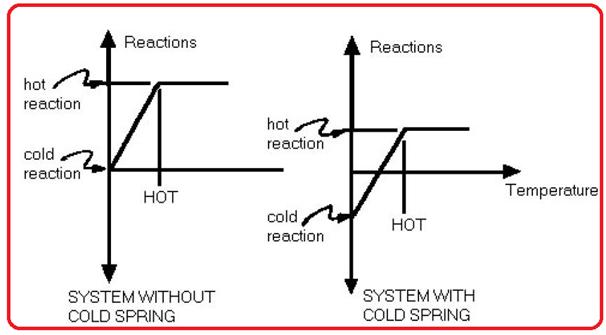

A system without Cold Spring Vs System with Cold Spring:

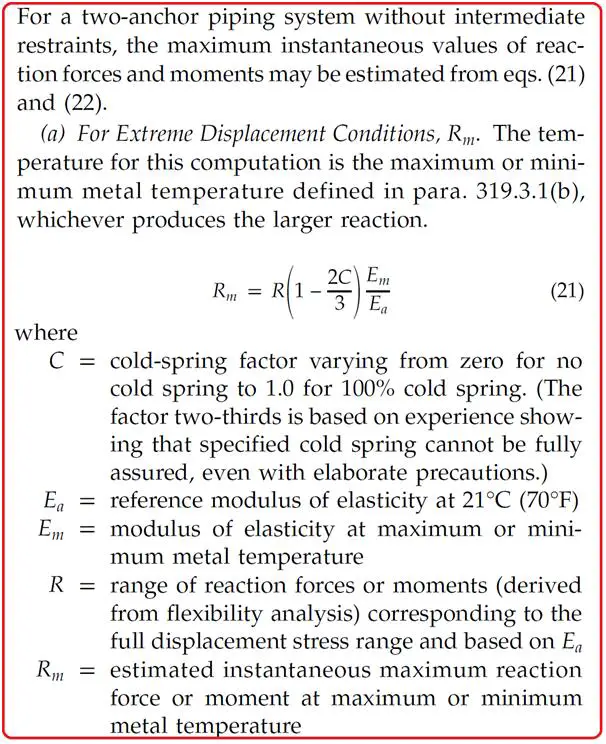

End Reaction at Design Temperature (as per B31.3):

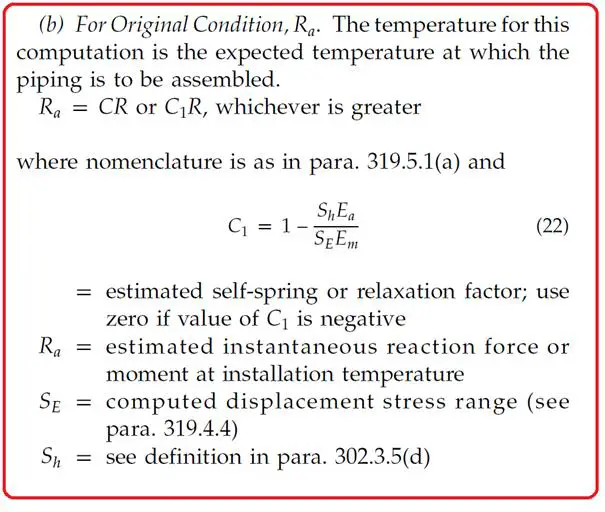

End Reaction at Installation Temperature (as per B31.3):

Cold Spring as per ASME B31.3

- The use of the above equations is valid for a two-anchor piping system without intermediate restraints

- For multi-anchor piping systems and for two-anchor systems with intermediate restraints above equations (21 and 22 as per B31.3) are not applicable.

- Each case must be studied to estimate the location, nature, the extent of local overstrain, and its effect on stress distribution and reactions.

- Code allows us to apply cold spring credit in calculating the thrusts and moments where actual reactions, as well as their range of variations, are significant.

- Code restricts us from applying cold spring credit in stress range calculations. This is because the piping system is affected more by the range of stress variation than by the magnitude of stress at a given time.

- Where cold spring is used in the piping system, experience has shown that it cannot be fully assured. Therefore, the reactions shall be computed for two cases. First, with the assumption that only two-thirds of the design cold spring is present, and second, with the assumption that four-thirds of the design cold spring is present. That effectively suggests calculating and comparing the end reactions from a couple of Caesar runs. First being one with only two-thirds of the cold spring and another using four-thirds. The results in both cases should be satisfactory. This is especially valid for computer analysis.

Both the sustained loads and the operating loads should be within the manufacturers’ allowable for the particular piece of equipment.

Cold Spring factor (C)

The following procedure explains how to get cold spring factor –

- Understand the system and decide in which direction the application of cold spring will give us maximum benefit.

- Get the maximum displacement corresponding to the direction in which the cold spring is planned. This can be found in the displacement report using Caesar II.

- The factor is then decided by the amount of cold spring applied to the system with respect to the expansion.

- A 100 percent cold-sprung system will have zero loads in expansion cases.

For Example:- If we have 80mm displacement during the hot conditions in say Y direction and we decide to give 40 mm of cold spring then it shall be a 50% cold sprung system. Hence cold spring factor will be 0.5. Click Here to read the next article on “How Cold Springing is applied at the site”.

Is expansion loop is example of cold pull.