An electric submersible pump (ESP) is an artificial lift pump that uses a motor to power a centrifugal pump through a series of stages to draw fluids and other materials out of a well. An ESP is a type of water pump that is designed to be immersed in a body of liquid and operates using an electric motor. The motor is connected to the pump and is sealed in a watertight casing, allowing the pump to be placed deep in wells, tanks, or reservoirs. ESPs are commonly used for pumping water or oil in oil wells, water wells, and other industrial or agricultural applications.

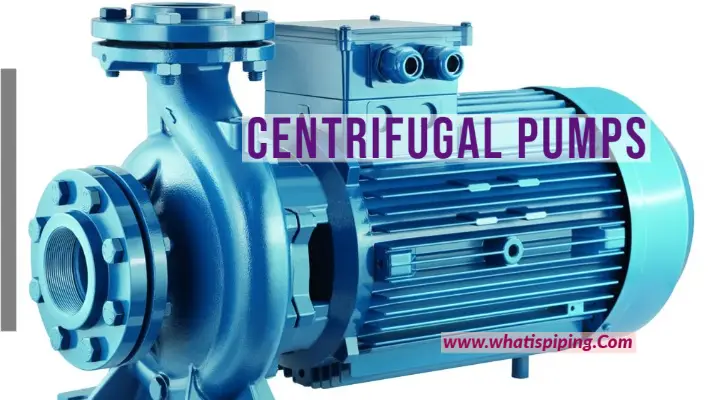

It is a multistage centrifugal pump that provides engineers with a flexible flow range and head. In addition, their high degree of energy economy makes them a good choice for various applications. An electrical submersible pump converts the liquid’s kinetic energy into work to increase pressure. These artificial lift pumps have recently gained popularity because of their widespread use on farms.

Historical Overview of Electrical Submersible Pump

In 1916, Russian inventor Armais Arutunoff was credited with developing the first electrical submersible pump. After moving to the United States in 1923, he established a company called the Russian Electrical Dynamo of Arutunoff (REDA). In the USA, he began seeking funders for his apparatus.

Initially, he presented his concept to Westinghouse, but it closed because the company’s engineers considered it impossible due to the principles of electronics. Later on, Arutunoff provided the solution to Phillips Petroleum’s problem in 1927 when the company was looking for a high-volume production method to make its high water-cut wells more profitable.

In the late 20th century, the company was a subsidiary of Schlumberger and held the title of the world’s largest manufacturer of electrical submersible pumps. There was no connection between REDA Pump Company and any other business until 1969. It was acquired by Schlumberger in 1998 when that firm bought CAMCO.

Electrical Submersible Pump (ESP) System

A multistage centrifugal pump powers an ESP system’s series of centrifugal pumps to draw fluid to the surface of the well. The ESP system is discussed as follows:

Turning on the ESP system

Even though the electrical submersible pump will run on a constant frequency supply, a soft starter or VSD can be used to get it going and clean out the well before the operation. It will allow the well to be cleaned up, production to begin at a low flow rate, and then ramped up as the well is rehabilitated.

Working Principle of ESP

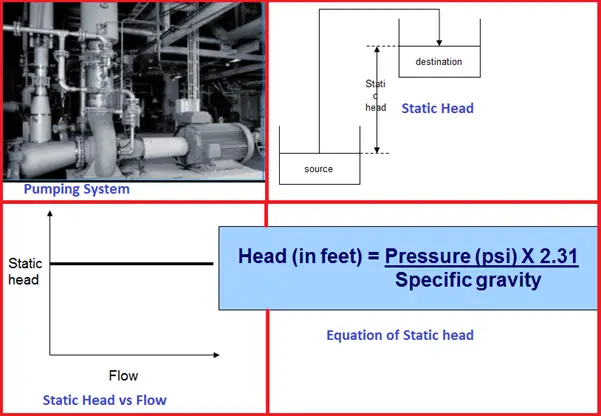

A vertically oriented centrifugal pump in a borehole is the heart of an electrical submersible pump, which increases the speed of fluids with the help of impellers. The diffuser takes the fluid pumping energy created by the impellers and transforms it into pressure energy.

In addition, the stages of an ESP System are typically configured with an impeller and diffuser. When liquid is pumped through the first stage’s impeller, its radial outward velocity is increased and centrifuged in the process. The fluid’s kinetic energy is turned into pressure as it reaches the diffuser from the impeller’s sharp edges.

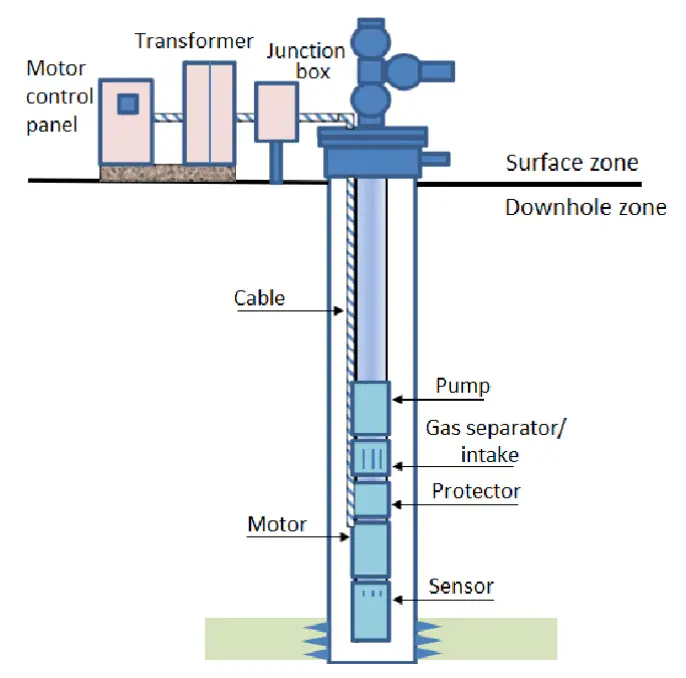

Components of Electrical Submersible Pump

The components are typically comprised of tubing hung from the wellhead. The pump is attached to the tubing above the motor, and the motor is attached to the tubing below. Refer to Fig. 1 which shows the components of a typical electrical submersible pump system.

The following is a closer look at each component.

1. Centrifugal Pump

The pump’s job is to provide the fluid with additional lift or transfer pressure to get the fluid to flow out of the wellbore at the required pace. It achieves this goal by first incorporating the fluid with kinetic energy by applying centrifugal force and then transforming that kinetic energy into potential energy by applying pressure. Pumps are manufactured in various diameters, so they may be used in the most common casing sizes.

2. Electric Motor

An electric motor drives the electrical submersible pump. Several steps are required to generate adequate head pressure to raise the liquid to the surface. The motor size and horsepower determined the number of stages.

Moreover, motor size is the primary factor in determining ESP bottom-hole equipment’s total length and diameter. As the motor’s temperature rises during operation, the fluid is pulled into the pump to cool it.

3. Power Cable

ESP motors receive the necessary surface power through the ESP power cable. As it is not meant to bear any weight, it is usually banded or fastened to the production tubing running from the wellhead to the ESP unit. The three-phase electrical wire builds under the harsh conditions of a well.

Similarly, an electrical submersible pump has a strong power cable with an outer covering resistant to mechanical and electrical stress. Due to the harsh conditions in the well, the cable must be designed to be tiny in diameter, guarded against mechanical abuse, and resistant to physical and electrical damage.

4. Controllers

The surface controller of an artificial lift pump is responsible for supplying power to the ESP motors and protecting the downhole ESP components from environmental hazards. Depending on the task, either variable-speed controllers or soft-start controllers are used.

- A VSD, or variable speed drive, can be operated either mechanically or electronically in an electrical submersible pump.

- The operating speed of a soft-start controller is fixed. Slowly but surely, it brings the pump motor up to its optimal operating speed and holds it there in a multistage centrifugal pump.

5. Sensor

Installing a bottom-hole sensor that relays information in real-time about system parameters, including pump intake and output pressures, temperatures, and vibrations, can help operators maximize efficiency.

A sensor on the pump sends a real-time alarm to the operator if the reading is outside of the preset range, and the surface controller can make adjustments remotely or automatically.

ESP Installation

1. Refueling the Engine

In the pump, set the motor in a vertical position on its base, double-checking and retightening any bolts as necessary. Ensure the engine is well hydrated by adding clean, cold water, rock the motor back and forth to remove any trapped air, and screw the plugs back in. Moreover, make sure there is no water leakage, and fix it.

2. Waterproofing the Wires

The flat, three-core PVC-insulated cable connecting the submersible motor to the surface is three meters long. Therefore, make a watertight connection between the free end of the motor cable and the supply cable from the control panel in an artificial lift pump.

3. Take a Look at the Valves

Ensure the well’s valves are closed while the electrical submersible pump is not in use to keep water from leaking back into the well.

4. Testing the Motor’s Rotational Direction

Verify the submersible motor’s rotational direction after connecting the supply cable and motor cable watertight. According to the markings on the cable box, the proper rotational movement is anticlockwise. Now plug the motor into the control box and turn the switch on for a moment. To validate the sand guard’s rotational axis, clean water should pour over it. Then change the direction of rotation by switching any two lead wires in the control panel if the markings on the cable box are incorrect.

5. Controlling for Rotational and Tactical Freedoms

In an electrical submersible pump, make sure the shaft of the pump and motor may freely spin and move up and down.

6. Connecting the Pump to the Submerged Motor

After that, put together the tripod and the chain link and disconnect the submersible pump’s cable guard and filter. Maintain a vertical position of the artificial lift pump using the submersible motor and use a grub screw to attach the connection to the drive shaft or pump shaft. Screw the delivery pipe into the delivery casing after applying the threading compound. Raise the shaft once it’s assembled, and look for wiggle room.

Furthermore, install the connection onto the pump’s motor shaft, and lower the pump until it is flush with the inlet bracket. Finally, suspend the submersible pump from the chain block, and secure the supply hose with the clamp.

7. Installing an Electrical System

In installing an electrical submersible pump, connect the submersible motor’s control panel to the engine with a single cable and then protect the underwater motor with grounding. Insist on a watertight connection at the cable’s end. Afterward, remove any excessive cable length and secure it to the engine’s starter terminals. When deciding on a wire size, keep low-voltage operating in mind.

8. Lowering the Pump Securely

Lastly, connect a T-handle end of a poly rope to the pump’s lug and attach the end of the safety rope to the inner well cap on both ends. Make sure the outer well cover is securely fastened on the pump, and finish connecting the power wires.

Maintenance of Electrical Submersible Pump

There are certain guidelines on how to operate and maintain a facility and how to resolve any difficulties that may develop. After the ESP has been extracted from the well, its components can be disassembled and analyzed for information. It is true whether the structures are salvageable or have suffered a complete collapse. Some guidelines for maintaining a multistage centrifugal pump are discussed below:

a. Check for Indications of Overheating

Check for indications of overheating the multistage centrifugal pump. If there is inadequate water in the well to cool the pump, or if the pump is faulty, the pump may overheat.

b. Create Oil and Start the Motor

It is essential to regularly grease your pump to ensure its smooth operation.

c. Examine the Engine

The pomp’s motor must also inspect often. Ensure that all connections of the artificial lift pump are tight and that the starter is not overheated.

d. Replace the Hoses and Fix the Leaks

The seals and hoses of the electrical submersible pump are susceptible to wear and strain. If they are not periodically inspected, they can cause significant damage once they begin to fail.

Applications of Electrical Submersible Pump

The artificial lift pump is superior to other types because it may be used in various flow rates and depths and produce a significant artificial lift. A multistage centrifugal pump increases output by creating a more substantial bottom pressure than the natural production dynamic.

Moreover, these artificial lift pumps are used for various applications, including drainage, irrigation, water wells, slurry pumping, fire-fighting, sewage pumping, artificial lifts, seawater handling, oil wells, sewage treatment, deep well drilling, mine dewatering, offshore drilling rigs.

- The artificial lift pump provides power for agricultural and industrial irrigation systems

- Flooded areas are pumped out at construction sites

- Sewage and sludge are common uses for these pumps. Pressure and level sensors are installed beneath the sewage levels to control the system.

- A multistage centrifugal pump transports the crude oil to surface processing and storage tanks.

- Oil is piped from deep underground wells to aboveground storage tanks

- Submersible pump cables must be dependable and resistant to the elements if they are to be used in harsh environments. The power cables of the multistage centrifugal pump are suitable for use in both fresh and saline water.

Advantages of ESP

The benefits of an artificial lift pump are mentioned below:

- Installed in straight sections, it can accommodate wells with a maximum inclination of horizontal

- The multistage centrifugal pump allows for higher output despite inevitable water cuts due to pressure checks and secondary recovery

- Being low-noise, low-risk, and low-impact means it can use in offshore and environmentally sensitive locations without causing too much disruption

- Artificial lift pumps can withstand high GOR fluids, high temperatures, and corrosive acid gases found in good settings.

- The electrical submersible pump has the capacity for large volumes, allowing for adaptation to changing fluid characteristics and flow rates over the well’s operational lifetime

Disadvantages of ESP

The disadvantages of multistage centrifugal pumps are mentioned below:

- The well’s curvature limits its usability during deployment and landing.

- Particles in production must keep to a minimum; fluids containing even trace amounts of sand and solids can significantly affect the system.

- When a motor’s seals erode, water might seep inside and stop it from working until they’re fixed. The pump’s construction makes repairs tricky.

- Equipment with moderate to high output rates necessitates casings with large outside diameters (more than 4.5 inches).

- When calculating the tension and deflection of a part, manufacturers must take dogleg severity into account to guarantee correct assembly and functionality.

Conclusion

When selecting a pumping system, engineers and operators increasingly discover multistage centrifugal pump is the optimum option for downhole and surface applications. The electrical submersible pump industry is developing more durable pumps to make ESP systems more practical under conditions of high solids flow. To significantly extend the lifespan of artificial lift pumps, ongoing research focuses on enhancing the dependability of both individual components and integrated systems, as well as creating improved algorithms for operating surveillance and control.

Frequently Asked Questions (FAQs)

Q1: What are the primary reasons a multistage centrifugal pump stops functioning?

A: There are typically five leading causes for an artificial lift pump to stop working. Among these are issues associated with heat and overload, fluid pressure, motor seals, power surges, and stable voltage.

Excellent Write-up, Anup Kumar