Petroleum refining is a complex process that transforms crude oil into valuable products like gasoline, diesel, jet fuel, heating oil, and various petrochemicals. This article will delve into the intricacies of crude oil refining, detailing the processes involved, the technologies utilized, and the environmental considerations associated with the industry.

What is Crude Oil

Crude oil is a naturally occurring, unrefined petroleum product composed of hydrocarbon deposits and other organic materials. It varies in composition depending on its source, influencing its refining process. The key components include:

- Alkanes (paraffins)

- Cycloalkanes (naphthenes)

- Aromatics

- Asphaltenes (heavy compounds)

Crude oil is classified into various categories, including light, medium, and heavy crude, with different refining implications.

What is Petroleum Refining?

Petroleum Refining is defined as the industrial process of production of useful petroleum products from crude oil. Crude oil in its raw form is a dark and sticky liquid which is not useful. To get usable products from crude oil, it needs to be refined. The plant where the useful products are separated from crude oil is known as a petroleum refinery. In this article, we will explore more about the process of Petroleum Refining-the crude oil refining processes.

How is Petroleum Refined? | What are the stages of oil refining?

Crude oil or petroleum consists of various hydrocarbons. The crude oil refining process breaks the crude oil down into various components to make useful new products. This petroleum refining is a very complex process and requires highly expensive industrial facilities. The basic crude oil refining process steps involved in all petroleum refining for the production of usable products are

- Distillation/Separation

- Atmospheric Distillation

- Vacuum Distillation

- Conversion

- Cracking

- Reforming

- Alkylation

- Polymerization

- Isomerization

- Coking

- Visbreaking

- Treatment, and

- Blending

Crude Oil Distillation Process in Petroleum Refining

The first process in the crude oil refining process steps is the distillation process inside a fractionation distillation column. The crude oil from the storage tanks is processed through desalters to remove the excess salt. It is then heated to a temperature of about 4000C in a crude oil heater and then routed to the Crude Distillation Unit or CDU.

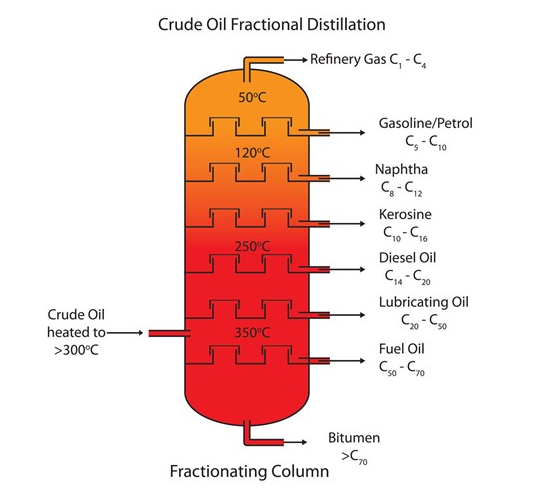

The main principle of distillation is to vaporize a liquid by heating it at its boiling point and then recondensing and collecting. This same principle is used to separate different compounds from crude oil inside the fractionation distillation column. A temperature gradient is maintained throughout the height of the column. The lower boiling, high volatile hydrocarbons are separated at the top of the column while less volatile, higher boiling products are separated towards the bottom of the column. A reboiler supplies heat at the bottom of the distillation column and the top is cooled by an overhead condenser. So, temperature decreases as the height of the fractionation column increases.

The boiled crude oil (liquid/gas mixture) at the bottom of the distillation column creates its vapor which rises through the vertical column passing through the holes in the distillation trays. As temperature decreases when gas rises through the tower, certain hydrocarbon components condense once one component cools below its boiling point. This separation occurs at different temperatures at different height levels and is collected through the trays. Different boiling-point cuts of different hydrocarbons allow them to be separated out in a single distillation process. The typical Crude oil distillation cuts are presented in Table 1 below:

| Hydrocarbon Fraction | Boiling Point Cut/Distillation Range (0C) |

| Gases (C1-C4) | <=50 |

| Gasoline/Petrol (C5-C7) | 50-100 |

| Naphtha (C8-C11) | 80-200 |

| Kerosene (C11-C12) | 170-280 |

| Light Diesel (C13-C17) | 220-320 |

| Heavy Diesel (C18-C25) | 290-350 |

| Atmospheric Residue (C25+) | 350-390 |

Refer to Fig. 1, which shows the compounds of crude oils separated at different temperatures in a fractionation distillation column.

Conversion Processes in Crude Oil Refining

In this process, residual oils, fuel oils, and light ends are converted to high-octane gasoline, jet fuel, and diesel fuel. Processes like cracking, coking, visbreaking, etc. are used to break large petroleum molecules into smaller ones.

Cracking in Petroleum Refining

Cracking during the crude oil refining process is a very important process where heavy hydrocarbon molecules from the crude oil are broken down into lighter shorter molecules. There are three cracking processes that are used in petroleum refineries. They are

- Thermal Cracking: Uses intense heat to break down the heaviest hydrocarbon molecules into smaller ones. Usually used to convert residual oil to fuel oil, petrol, diesel, and naphtha.

- Hydro Cracking: This process breaks down the larger molecules of gas oil, kerosene, and naphtha and produces petrol. The Hydrocracking process consists of using hydrogen in the presence of a catalyst at high pressure at around 4000C. This process also removes impurities like sulfur, nitrogen, and metal traces.

- Catalytic Cracking: In the catalytic cracking process, the gas oil or residual oil is broken down into petrol and diesel using intense heat in the presence of a catalyst. This method produces high-quality products compared to other cracking methods.

Reforming in Crude Oil Refining

The reforming process in Petroleum refining increases the production volume of gasoline from each barrel of crude oil. The reforming process basically rearranges the hydrocarbon molecules of similar carbon atoms and naphtha molecules to convert them into gasoline molecules.

The Alkylation or Catalytic Polymerisation process in crude oil refining converts propene and butene molecules into high-octane hydrocarbons by combining them in the presence of an acid catalyst. This process combines smaller hydrocarbons, such as isobutane and olefins, in the presence of an acid catalyst to produce high-octane gasoline components. Alkylation is vital for enhancing the octane rating of fuels.

The Isomerisation process in petroleum refining converts straight-chain hydrocarbons to branched chains which improves hydrocarbon quality. Isomerization rearranges hydrocarbon structures to improve octane ratings. For example, converting normal butane to isobutane enhances fuel quality.

Treating in Crude Oil refining Process

Treating in petroleum refining processes stabilizes and upgrades petroleum products by removing less desirable products and contaminants or objectionable elements. Products like sulfur, nitrogen, oxygen, salts, dissolved metals, etc are usually present which must be removed to improve the petroleum quality. Various processes used in treating are hydrodesulfurization, hydrotreating, chemical sweetening, desalting, deasphalting, hydrogen sulfide scrubbing, and acid gas removal.

The selection of a proper treatment method is dependent on various factors like:

- the nature of the petroleum fractions,

- amount and type of impurities in the fractions to be treated,

- the extent to which the process removes the impurities, and

- end-product specifications.

The treating process can be an intermediate stage in the crude oil refining process, or the products can be treated just before sending the finished product to storage. Various treating materials include acids, alkalis, oxidizing, solvents, and adsorption agents.

Key treatment processes include:

Hydrotreating

Hydrotreating uses hydrogen to remove sulfur, nitrogen, and oxygen from petroleum fractions. It is critical for meeting environmental regulations regarding sulfur content in fuels.

Desulfurization

Specific desulfurization processes are employed to lower sulfur levels, essential for producing ultra-low sulfur diesel (ULSD).

Sweetening

Sweetening processes remove sour compounds (mercaptans and hydrogen sulfide) from products, improving odor and stability.

Petroleum Blending Process in Crude Oil Refining

Blending is the last step in the petroleum refining process and is quite complicated. The blending process involves the optimal mixing of various petroleum components to achieve the final finished product requiring specific octane specifications. The final cost of the product is also decided based on the proper blending of the components. The blending processes in crude oil refining are very important to achieve desired properties like viscosity, flashpoint, pour point, octane number, etc. Different processes are used to blend components like:

- In-line blending through a manifold system

- Batch blending in tanks

- Onboard blending into marine vessels

Usually, four product blending pools are typical in a refinery. They are:

- LPG Pool for blending saturated C3s and C4s.

- Gasolene Pool: Most important and complex blending pool to produce premium and regular gasolene products by blending appropriate amounts of n-butane, reformate, light naphtha, alkylate and light cracked naphtha.

- Gas Oil/Diesel Pool to blend Kerosene, slurry, LGO, and LVGO.

- Fuel oil/Bunker Oil Pool to blend LVGO, slurry, and cracked residue.

Products from Crude Oil Refining Process

The various usable end products that are produced after petroleum refining in a refinery are:

- Light distillates

- C1 and C2 components

- Gasoline (petrol)

- Light naphtha

- Liquified petroleum gas (LPG)

- Heavy naphtha

- Middle distillates

- Automotive and railroad diesel fuels

- Kerosene

- Residential heating fuel

- Other light fuel oils

- Heavy distillates

- Wax

- Lubricating oils

- Heavy fuel oils

- Asphalt

- Others

- Coke (similar to coal)

- Elemental sulfur

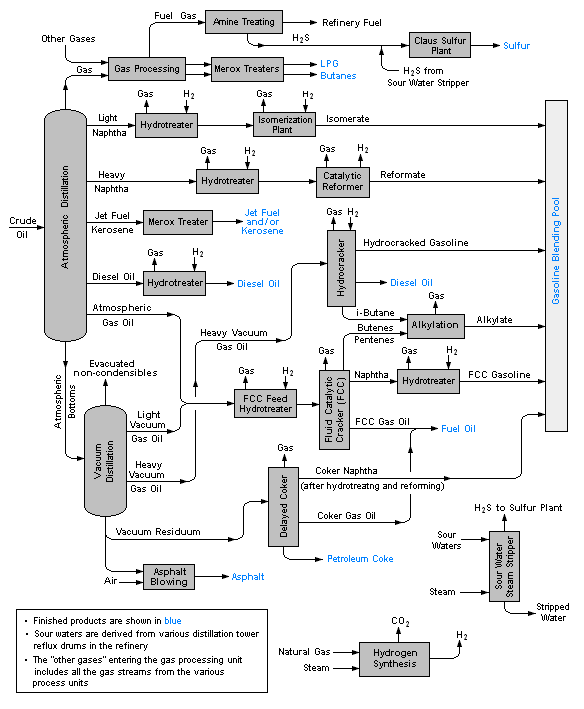

The image in Fig. 2 below shows a schematic flow diagram of the petroleum refining processes in a crude oil refinery.

Online Courses on Petroleum Refining

To learn more about the petroleum refining process steps, the following three online courses are highly recommended:

- Petroleum refining demystified – Oil & Gas industry

- Petroleum Refining – Complete Guide to Products & Processes

- Petroleum Refinery: Simplified

These online petroleum refining courses will guide you step-by-step in processes like Distillation, Isomerization, Alkylation, Reforming, Hydrofining, and Fluid Catalytic Cracking. You will learn how the main petroleum products like LPG, gasoline, kerosene, diesel fuel, heating oil, heavy fuel, asphalt, lubricants, etc are made.

Petroleum refining is a multifaceted process essential to modern society. Understanding the intricacies of crude oil refining, from distillation to blending, highlights the technological and economic complexities involved. As the world shifts toward sustainability, the refining industry must adapt, embracing innovations and prioritizing environmental stewardship.

Nice article. Can i get pdf copy ?

Anup I just read your report on piping it is wonderful . If you can share the detailed copy that will be great. Also I’m involved in some funds raising for a oil and gas client if we can be in touch that will be great

This is a very good article. I am a High School Geography teacher and one of the topics I have to tackle is Petroleum in the World. This article has helped me a lot and I have gained so much information which will help me when teaching my students on this topic.