Power piping plays a crucial role in the operation and performance of various industrial systems associated with power generation systems. These systems involve the transportation of steam, compressed air, and other high-pressure fluids necessary for power generation, manufacturing, chemical processing, and more. Properly designed and installed power piping systems are essential for ensuring safety, efficiency, and reliability in industrial facilities. In this article, we will delve into the significance of power piping and explore the key considerations in its design.

What is Power Piping?

ASME defines power piping as the piping which is found in electric power generating stations, industrial and institutional plants, geothermal heating systems, and central and district heating and cooling systems. The power piping system is designed based on the ASME B31.1 code.

Importance of Power Piping

Power piping is the backbone of numerous industrial processes that heavily rely on high-pressure fluids. Its significance can be highlighted in the following areas:

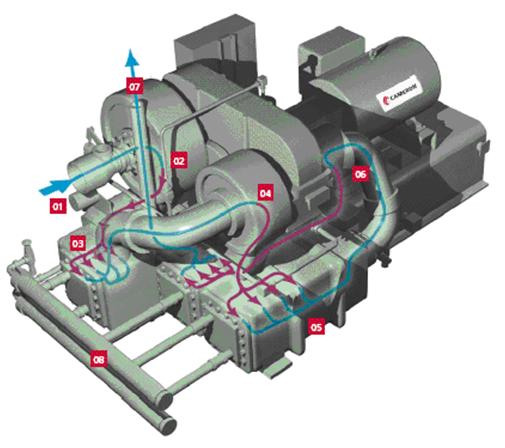

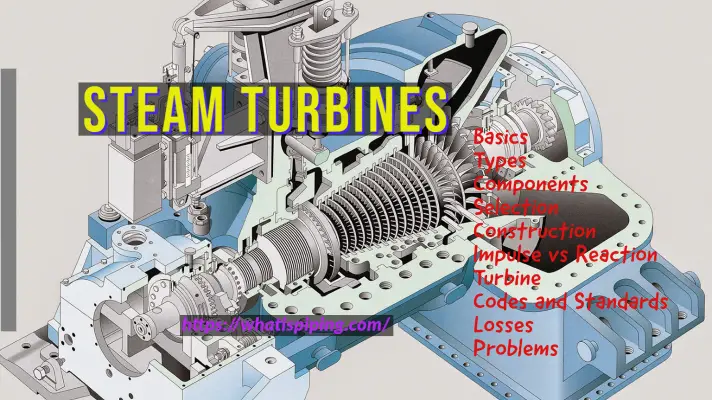

- Power Generation: In thermal power plants, power piping carries steam from boilers to turbines, facilitating the generation of electricity. It also transports various cooling fluids in nuclear power plants.

- Manufacturing: Industries such as steel, cement, and paper rely on power piping for compressed air, steam, and other high-pressure media that drive machinery and equipment.

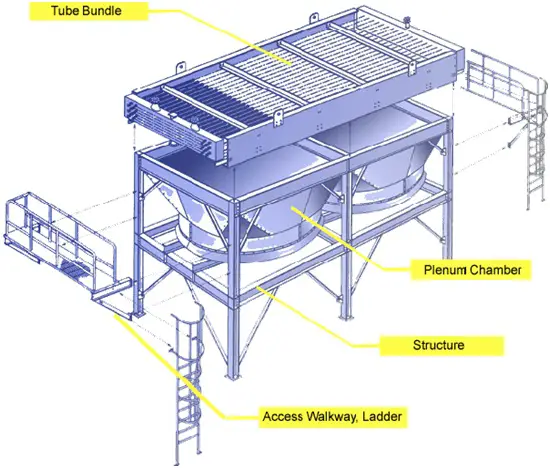

- HVAC Systems: In commercial and industrial buildings, power piping circulates high-pressure fluids to manage heating, ventilation, and air conditioning systems.

Design Considerations for Power Piping

The design of power piping systems demands meticulous planning and adherence to the ASME B31.1 code to ensure safety, longevity, and optimal performance. Below are the key considerations to take into account during the design phase:

- Code Compliance: Power piping must comply with international standards such as ASME B31.1. These codes define design, construction, inspection, and testing criteria to guarantee the integrity of the system.

- Material Selection: Choosing the right materials for power piping is vital. Factors like fluid type, pressure, temperature, and environmental conditions impact material selection. Common materials include carbon steel, stainless steel, alloy steel, and non-metallic materials like plastic and fiberglass-reinforced piping.

- Stress Analysis: Conducting pipe stress analysis is critical to ensure that the piping system can withstand operating conditions and potential transient events without failure. Advanced computer simulations help engineers identify stress concentrations and ensure proper support and flexibility.

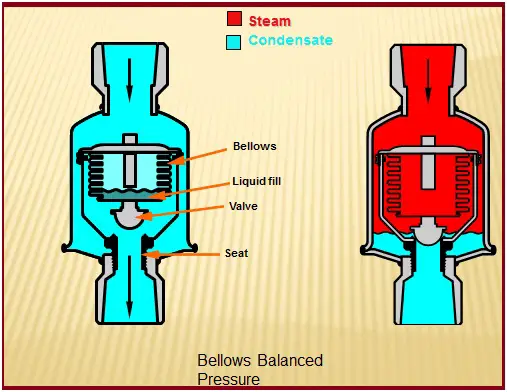

- Safety Measures: Implementing safety features such as pressure relief valves, rupture discs, and pressure regulators mitigates the risk of overpressure incidents, safeguarding personnel and equipment.

- Welding and Joining: The welding and joining processes must adhere to industry standards to maintain the structural integrity of the system. Skilled welders, non-destructive testing (NDT), and rigorous inspections are essential for secure connections.

- Corrosion Protection: High-pressure fluids can lead to corrosion, reducing the lifespan of power piping. Employing appropriate coatings, cathodic protection, or using corrosion-resistant materials can minimize this risk.

- Expansion Joints: Power piping systems experience thermal expansion and contraction during operation. Incorporating expansion joints accommodates these movements and prevents excessive stress on the piping components.

Power Piping Codes and Standards

ASME B31.1 is the main code that is followed for guidelines of the design, material selection, testing, and construction of power piping systems. There are many other codes, standards, and specifications that are followed to properly design each component of the power piping system. Table 126.1-1 of ASME B31.1 lists all such codes. Some of the notable codes and standards associated with power piping are listed below:

| Code/Standard/Specification | Title |

|---|---|

| AISC Publication | Manual of Steel Construction Allowable Stress Design |

| American National Standard Z223.1 | National Fuel Gas Code (ANSI/NFPA 54) |

| API-5L | Line Pipe |

| API-570 | Piping Inspection Code: In-Service Inspection, Rating, Repair, and Alteration of Piping Systems, Third Edition |

| ASCE/SEI 7 | Minimum Design Loads and Associated Criteria for Buildings and Other Structures |

| ASME-B1.1 | Unified Inch Screw Threads |

| ASME-B1.13M | Metric Screw Threads — M Profile |

| ASME-B1.20.1 | Pipe Threads, General Purpose (Inch) |

| ASME-B1.20.3 | Dry-seal Pipe Threads (Inch) |

| ASME-B16.1 | Gray Iron Pipe Flanges and Flanged Fittings — Classes 25, 125, and 250 |

| ASME-B16.3 | Malleable Iron Threaded Fittings |

| B16.4 | Gray Iron Threaded Fittings |

| B16.5 | Pipe Flanges and Flanged Fittings |

| B16.9 | Factory-Made Wrought Buttwelding Fittings |

| B16.10 | Face-to-Face and End-to-End Dimensions of Valves |

| B16.11 | Forged Fittings, Socket-Welding and Threaded |

| B16.14 | Ferrous Pipe Plugs, Bushings, and Locknuts With Pipe Threads |

| B16.15 | Cast Bronze Threaded Fittings, Classes 125 and 250 |

| B16.18 | Cast Copper Alloy Solder-Joint Pressure Fittings |

| B16.20 | Metallic Gaskets for Pipe Flanges — Ring Joint, Spiral Wound, and Jacketed |

| B16.21 | Nonmetallic Flat Gaskets for Pipe Flanges |

| B16.22 | Wrought Copper and Copper Alloy Solder Joint Pressure Fittings |

| B16.24 | Cast Copper Alloy Pipe Flanges and Flanged Fittings — Class 150, 300, 400, 600, 900, 1500, and 2500 |

| B16.25 | Butt Welding Ends |

| B16.26 | Cast Copper Alloy Fittings for Flared Copper Tubes |

| B16.34 | Valves — Flanged, Threaded, and Welding End |

| B16.36 | Orifice Flanges |

| B16.42 | Ductile Iron Pipe Flanges and Flanged Fittings — Classes 150 and 300 |

| B16.47 | Large Diameter Steel Flanges |

| B16.48 | Steel Line Blanks |

| B16.50 | Wrought Copper and Copper Alloy Braze-Joint Pressure Fittings |

| B18.2.1 | Square and Hex Bolts and Screws — Inch Series |

| B18.2.2 | Square and Hex Nuts (Inch Series) |

| B18.2.3.5M | Metric Hex Bolts |

| B18.2.3.6M | Metric Heavy Hex Bolts |

| B18.2.4.6M | Hex Nuts, Heavy, Metric |

| B18.21.1 | Lock Washers (Inch Series) |

| B18.22M | Washers, Metric Plain |

| B18.22.1 [Note (1)] | Plain Washers |

| B18.31.1M | Metric Continuous and Double-End Studs |

| B18.31.2 | Continuous Thread Stud, Double-End Stud, and Flange Bolting Stud (Stud Bolt) (Inch Series) |

| B31.3 | Process Piping |

| B31.4 | Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids |

| B31.8 | Gas Transmission and Distribution Piping Systems |

| B31E | Recommended Practices for the Prevention of Water Damage to Steam Turbines Used for Electric Power Generation — Fossil-Fueled Plants |

| B31J | Stress Intensification Factors (i-Factors), Flexibility Factors (k-Factors), and Their Determination for Metallic Piping Components |

| B31P | Standard Heat Treatments for Fabrication Processes |

| B31T | Standard Toughness Requirements for Piping |

| B36.10M | Welded and Seamless Wrought Steel Pipe |

| B36.19M | Stainless Steel Pipe |

| BPVC | Boiler and Pressure Vessel Code |

| TDP-1 | Recommended Practices for the Prevention of Water Damage to Steam Turbines Used for Electric Power Generation — Fossil Fueled Plants |

Differences between Power Piping and Process Piping

The major general differences between power piping and process piping are provided in Table-2 below:

| Aspect | Power Piping | Process Piping |

|---|---|---|

| Purpose | Transports high-pressure fluids for power generation and utility applications. | Carries various fluids used in industrial processes like chemical manufacturing and oil refining. |

| Fluid Type | Typically involves steam, compressed air, and other high-pressure media. | Involves a wide range of fluids, including gases, liquids, and multiphase mixtures. |

| Pressure Rating | High-pressure systems, often exceeding 1000 psi (6.89 MPa) and more. | May include high, medium, or low-pressure systems, depending on the process requirements. |

| Temperature Range | High-temperature applications, commonly above 250°F (121°C). | Varies depending on the process, ranging from low to high temperatures. |

| Codes and Standards | ASME B31.1 – Power Piping Code is commonly used. | ASME B31.3 – Process Piping Code is widely applied. |

| Safety Factors | Emphasis on structural integrity and safety due to high pressures and temperatures. | Safety considerations are still important but may focus more on the process and materials. |

| Design Complexity | Often involves simpler designs with fewer connections. | More complex designs with multiple connections, branch lines, and process-specific considerations. |

| Material Selection | Commonly carbon steel, stainless steel, and alloy steel. | Diverse material choices, including plastics, fiberglass, and corrosion-resistant alloys. |

| Testing and Inspection | Rigorous testing and inspection requirements due to the criticality of power generation. | Inspection standards may be more flexible, depending on the process and its impact on safety. |

| Expansion and Flexibility | Less emphasis on expansion joints due to limited thermal expansion. | May require more expansion joints to accommodate thermal movements. |

| Maintenance and Shutdowns | Shutdowns for maintenance often scheduled based on plant operations. | Shutdowns are scheduled based on the process requirements and maintenance needs. |

| Industry Application | Power plants, utility systems, and energy production facilities. | Chemical, petrochemical, oil and gas, and other process industries. |

| Risk of Overpressure Incidents | High-pressure systems pose a significant risk of overpressure events. | Still a concern, but the risk can vary depending on the process and pressures involved. |

If you are looking for major differences between the power piping code (ASME B31.1) and the process piping code (ASME B31.3), then you may click here.

Conclusion

Power piping forms the lifeline of various industrial applications, enabling the transportation of high-pressure fluids critical for power generation, manufacturing, and chemical processes. The proper design and implementation of power piping are essential for maintaining safety, efficiency, and reliability in industrial operations.

Engineers must pay meticulous attention to code compliance, material selection, stress analysis, safety measures, welding, and corrosion protection during the design and construction phases. By doing so, they can ensure that power piping systems function optimally and safely, contributing to the smooth operation of industrial facilities worldwide.

Online Courses on Piping Design

If you wish to dig deeper and learn more about elements of piping design and engineering then the below-mentioned online courses will help you to do so:

- Designing Piping Systems: Pipe Fittings Flanges Valves

- Piping Isometrics demystified through practical examples

- Flow of fluids through piping systems , valves and pumps

- The Complete Course on Piping Components for Oil&Gas Career

- Piping Design Engineering & Piping Isometrics Masterclass

- PG Diploma in Piping Design Engineering

HI

I WANT TO LEARN POWER PIPING