A pressure-reducing valve is a self-operating valve that is used to reduce any excess pressure in a system. Sometimes this valve is also known as pressure reducing regulator. The basic function of pressure-reducing valves is to reduce higher pressure into lower. They are commonly used in water, steam, and oil & gas industries. A Pressure Reducing Valve can be defined as a self-acting automatic control valve for reducing a higher unregulated inlet pressure to a constant, reduced outlet pressure regardless of the fluctuations in the upstream water pressure. In this article, we will learn about the functions, types, applications, and advantages of pressure-reducing valves.

Functions of Pressure Reducing Valves

A pressure-reducing valve is able to control pressure through the fully automatic self-contained operation without the necessity of an external power source. The main functions of a pressure-reducing valve are:

- In steam systems, pressure-reducing valves are used to get precise control of downstream pressure. These valves automatically adjust the valve opening and adjust the pressure to keep it constant during pressure fluctuations.

- Properly selected pressure-reducing valves can be used for water hammer protection under defined conditions.

- They can also be used as bypass valves for saving the system during power failures.

- Pressure-reducing valves are capable of taking rapid action by immediate sensing and adjusting based on the downstream pressure.

Types of Pressure Reducing Valves

A pressure-reducing valve in a steam system works by balancing the steam pressure with a spring. Most of the modern pressure-reducing valves are manufactured using this basic concept. Based on the mechanism of controlling the valve opening, pressure-reducing valves are classified into two types:

- Direct acting pressure reducing valve and

- Pilot-operated pressure-reducing valve.

Direct-acting pressure-reducing valve:

Direct-acting pressure-reducing valves are ideal for small loads where precise pressure control is not required. They are manufactured in a compact size, cheap, and very easy to install. However, they usually have more variation from the set pressure as compared to their pilot-operated counterpart.

Direct-acting pressure-reducing valves are designed for point-of-use installation. This is the simplest type of pressure-reducing valve that operates with either a flat diaphragm or convoluted bellows. It does not need an external sensing line downstream to operate as it is self-contained. The accuracy of direct-acting PRVs is typically (+/-) 10% of the downstream set point.

In direct-acting pressure-reducing valves, the movement of the adjustment spring aids in the valve opening directly. The spring compression creates an opening force on the pressure-reducing valve which increases the flow. As pressure builds downstream, equalizing occurs by feeding the downstream pressure to the underside of the adjustment spring where its upward force counter-balances against the spring compression. The spring compressive force is limited to allow sufficient spring sensitivity to equalize with downstream pressure changes. This causes a simple pressure control through a valve orifice. However, high flow rates can cause pressure variation.

Pilot Operated pressure reducing valve:

Pilot-operated pressure-reducing valves are normally used for larger loads requiring close pressure control. They provide a faster response to load variation and are suitable for a wider range of flow rates as compared to the direct-acting types. They are larger in size and costly.

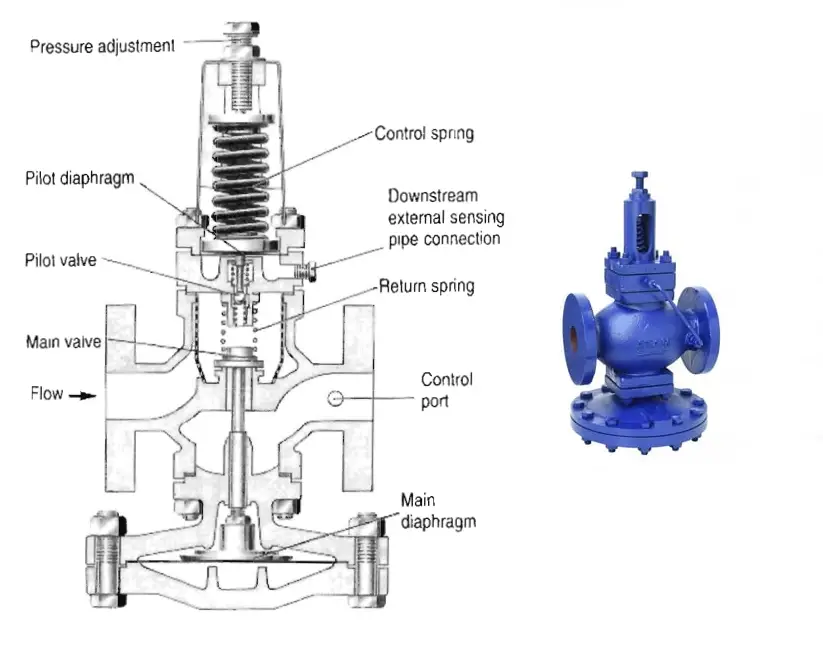

A pilot-operated pressure-reducing valve uses a pilot valve to load a piston or diaphragm that increases the downward force used to open a larger main valve. This helps in larger flow capacity with a lower pressure variation. By balancing the force between the adjustment spring and the secondary pressure, the opening and closing of the pilot valve are controlled. This pilot valve purposely delivers pressure to the main valve piston or diaphragm. The downward force created by this pilot flow pressure is amplified by the area of the piston or diaphragm that enables the opening of a much larger main valve providing the ability for very high flow rates.

Due to this amplification, a small change in the opening on the pilot valve results in a large change in flow and downstream pressure through the main valve. Therefore, a little change in adjustment spring force on the pilot accomplishes a quick response over a wide range of steam flow rates. The main advantage of a pilot-operated pressure-reducing valve is the quick response and tight downstream pressure control.

There are two types of pilot operated pressure reducing valves:

- Internally piloted piston operated that incorporates two valves-a pilot and main valve-in one unit. It provides an accuracy of +/- 5%.

- Externally piloted where double diaphragms replace the piston operator of the internally piloted design. this type of pressure-reducing valve provides an accuracy of +/- 1%.

The image in Fig. 1 shows the components of pilot operated pressure-reducing valve.

Applications of Pressure-Reducing Valves

Self-acting pressure-reducing valves are used in the following services:

Air or gas services: Both direct-acting and pilot-operated pressure-reducing valves for air and gas services are used in compressed air systems, power tools, pneumatic control systems, and control valves for industrial gas storage and distribution systems. The selection of the type of pressure-reducing valve for these services is based on the accuracy of control required.

Water services: Pressure-reducing valves find wide application in domestic and industrial water distribution services and fire protection systems. In general, direct-acting pressure-reducing valves are preferred for these services. During high-demand scenarios, maintaining system pressures becomes very difficult. Pressure-reducing valves are used in those lines which can effectively control the pressure downstream to an acceptable limit.

Steam services: The majority of the pressure-reducing valves are used in steam applications involving direct steam supply, steam engines, and turbines.

Other Services: Pressure-reducing valves find their applications in the following:

- Bearing lubrication systems in heavy industrial equipment and rolling mills.

- In hydraulic presses to control ram pressure.

- To control the pressure in fuel-oil systems.

- To reduce pressure in sterilizers, humidifiers, unit heaters, and small process equipment

Advantages of Pressure Reducing Valves

The main advantages of a pressure-reducing valve are:

- No requirement for an external power source.

- Separate measuring elements or feedback controllers are not required.

- Simple design with low cost.

- High reliability and easy maintainability

- External leakage and source of high friction are eliminated by the absence of stem packing.

- Fast response

Pressure Reducing Valve vs Pressure Relief Valve

The main differences between a pressure-reducing valve and a pressure-relief valve are

1.0 Pressure-reducing valves maintain almost constant pressure at the downstream side of the valve. So, this valve is used only to maintain or reduce the higher pressure. Whereas pressure relief valves are used to protect equipment and systems from high pressure when the system or equipment pressure exceeds the set limit.

2.0 Pressure-reducing valves operate continuously in the line whereas pressure-relief valves pop up only when the set pressure limit is exceeded.

3.0 In a pressure-reducing valve the pilot line senses the outlet pressure whereas in a pressure-relief valve the pilot line senses the inlet pressure.

4.0 In normal working conditions, the pressure-reducing valve will be in the open position but the pressure-relief valve remains in a closed position.

Thanks for continuing giving useful knowledge. Hats off.

My query:-

1) What is difference between PRV and Control Valve?

2) Are both same?

3) Can we say Pressure Relief Valve and Safety Valve are same?

Interesting!

Hello, thanks for you information.

You have aditional information over:

“Properly selected pressure reducing valves can be used for water hammer protection under defined conditions”

Regards

Pedro

It is very important to know every bit of Pressure Reducing Valves because it is a technical term. I think technically knowing these things becomes more important.

So, thanks for sharing these views.

This was very helpful thank you for sharing your knowledge.