Both Stainless Steel and Galvanized Steel are versatile and widely used materials in various industries due to their strength, durability, and corrosion resistance. However, each of them has its unique properties and applications. In this blog post, we will explore the major differences between Stainless Steel and Galvanized Steel.

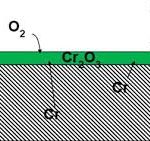

What is Stainless Steel?

Stainless steel is a corrosion-resistant alloy composed of iron, chromium, and other elements such as nickel and molybdenum. The chromium content in stainless steel forms a protective layer on its surface, known as a passive film, which prevents rust and corrosion. This makes stainless steel highly resistant to stains, oxidation, and corrosion, even in harsh environments. It is commonly used in applications requiring hygiene, such as kitchen appliances, medical equipment, and the construction industry.

What is Galvanized Steel?

Galvanized steel is regular carbon steel coated with a layer of zinc through a process called galvanization. This protective coating is achieved by immersing the steel in a bath of molten zinc or by electroplating it. The zinc coating provides galvanized steel with excellent corrosion resistance, as the zinc sacrificially corrodes before the underlying steel is affected. Galvanized steel finds extensive use in outdoor applications, construction, automotive parts, and agricultural equipment.

Differences between Stainless Steel and Galvanized Steel

| Parameter | Stainless Steel | Galvanized Steel |

|---|---|---|

| Corrosion Resistance | Stainless steel is highly corrosion resistant | Galvanized steel has good corrosion resistance, but is not as effective as stainless steel |

| Appearance | The appearance of stainless steel is reflective and shiny | The appearance of galvanized steel is dull and matte with a spangled texture |

| Maintenance | Requires minimal maintenance | Requires periodic maintenance to prevent rusting |

| Cost | More expensive than galvanized steel | Less expensive than stainless steel |

| Strength | Generally stainless steel is stronger than galvanized steel | Galvanized Steel has similar strength to regular carbon steel |

| Weldability | Stainless Steel has good weldability | Good weldability, but the zinc coating may affect the welding process |

| Environmental Impact | Recyclable and eco-friendly | The zinc coating can have environmental implications if not properly disposed of |

| Applications | Kitchen appliances, medical equipment, construction | Outdoor applications, construction, automotive parts, agricultural equipment |

Which is better, Galvanized Steel or Stainless Steel?

The answer depends on the specific application and requirements. Stainless steel offers superior corrosion resistance, making it an ideal choice for environments prone to moisture, chemicals, or high temperatures. It is well-suited for applications where hygiene and aesthetics are crucial, but it comes at a higher cost.

On the other hand, galvanized steel provides good corrosion resistance, especially in outdoor environments. It is more cost-effective than stainless steel and is commonly used in applications where strength, durability, and moderate corrosion resistance are required. However, in highly corrosive environments, galvanized steel may not provide the same level of protection as stainless steel.

What lasts longer, Galvanized Steel or Stainless Steel?

Stainless steel generally has a longer lifespan compared to galvanized steel due to its superior corrosion resistance properties. The protective passive film on stainless steel prevents rust and corrosion, allowing it to maintain its integrity and appearance for an extended period. Galvanized steel, while durable, is subject to eventual degradation as the zinc coating sacrificially corrodes over time. However, with proper maintenance and periodic inspection, both types of steel can have long lifespans.

Which is Stronger: Stainless Steel or Galvanized Steel?

When it comes to strength, it is important to consider the specific grades and types of galvanized and stainless steel being compared. In general, stainless steel tends to be stronger than galvanized steel.

Stainless steel is known for its high tensile strength, which means it can withstand higher levels of tension or pulling forces without deforming or breaking. The exact strength of stainless steel can vary depending on its alloy composition and the specific grade used. Certain grades of stainless steel, such as 304 or 316, are commonly used for their superior strength properties.

On the other hand, galvanized steel typically has a similar strength to regular carbon steel. The galvanization process involves coating carbon steel with a layer of zinc, which primarily provides corrosion resistance rather than significantly affecting its strength. The zinc coating does not substantially change the base steel’s mechanical properties.

It’s worth noting that the strength of steel can also depend on other factors such as the manufacturing process, heat treatment, and any additional alloying elements present. Therefore, it’s important to consult the specifications and standards relevant to the specific grades and types of steel being compared.

Which is Heavier: Galvanized Steel or Stainless Steel?

The density of stainless steel typically ranges from 7.7 to 8.0 grams per cubic centimeter (g/cm³) or 7700 to 8000 kilograms per cubic meter (kg/m³). It’s important to note that different grades of stainless steel can have slightly different densities. For example, austenitic stainless steel, such as the commonly used grade 304, has a density of around 8.0 g/cm³.

On the other hand, galvanized steel, being regular carbon steel with a zinc coating, has a density similar to that of carbon steel. The density of galvanized steel typically ranges from 7.6 to 7.8 g/cm³ or 7600 to 7800 kg/m³.

From the density difference itself, we can see that stainless steel is generally heavier than galvanized steel. The weight difference between the two is primarily due to the differences in their composition and density.

Which has Better Thermal Conductivity: Stainless Steel or Galvanized Steel?

Stainless steel and galvanized steel have different thermal conductivity properties. Stainless steel is known for its relatively low thermal conductivity compared to other metals. It is considered a poor conductor of heat. The thermal conductivity of stainless steel can vary depending on the specific grade and composition, but it generally ranges from 14 to 19 watts per meter-kelvin (W/(m·K)). This lower thermal conductivity makes stainless steel useful in applications where heat transfer needs to be controlled or minimized.

Galvanized steel, being primarily regular carbon steel with a zinc coating, has similar thermal conductivity to carbon steel. The thermal conductivity of galvanized steel can vary depending on the specific grade and thickness of the zinc coating. However, it is generally in the range of 50 to 60 W/(m·K). This higher thermal conductivity makes galvanized steel a better conductor of heat compared to stainless steel. Hence, stainless steel has a relatively low thermal conductivity, while galvanized steel has a higher thermal conductivity.

Choosing Between Stainless Steel and Galvanized Steel

Choosing between stainless steel and galvanized steel depends on several factors, including the specific application requirements, budget, aesthetic preferences, and environmental considerations. Here are some key points to consider when making a decision:

- Corrosion Resistance: If the application involves exposure to moisture, chemicals, or harsh environments, stainless steel is generally the preferred choice. It offers excellent corrosion resistance and is less prone to rust and degradation compared to galvanized steel.

- Strength and Durability: Stainless steel tends to be stronger and more durable than galvanized steel, especially when considering certain grades and types. If the application requires high strength and long-term structural integrity, stainless steel may be the better option.

- Cost: Galvanized steel is generally more cost-effective than stainless steel. If budget constraints are a significant factor, galvanized steel may be a suitable choice, especially for applications where moderate corrosion resistance is sufficient.

- Aesthetics: Stainless steel has a shiny, reflective appearance, making it popular in applications where aesthetics are important, such as kitchen appliances or architectural features. Galvanized steel has a dull, matte finish with a spangled texture. Consider the desired visual appeal when choosing between the two.

- Weldability: Both stainless steel and galvanized steel are generally considered to have good weldability. However, the zinc coating on galvanized steel can affect the welding process and may require additional precautions. Consult with a welding specialist to determine the feasibility and requirements for welding the chosen steel type.

- Environmental Considerations: Stainless steel is recyclable and considered more environmentally friendly compared to galvanized steel. The zinc coating on galvanized steel can have environmental implications if not properly disposed of or recycled.

It’s important to assess the specific requirements and constraints of your application and consult with professionals or experts in the field. They can provide guidance based on their knowledge and experience to help you make an informed decision.

Conclusion

In summary, stainless steel and galvanized steel are two distinct types of steel with different characteristics and applications. Stainless steel offers exceptional corrosion resistance, while galvanized steel provides good protection at a more affordable cost. The choice between the two depends on factors such as the environment, budget, aesthetics, and required durability. It is essential to consider these factors when selecting the appropriate steel type for a specific application.