GRP / GRE / FRP / HDPE piping modeling in START-PROF is as easy as for steel piping. Your job is only to select the appropriate code and choose the material. That’s all!

Difference between GRE/GRP/FRP and Steel

The main differences between GRP / GRE / FRP piping to steel piping are:

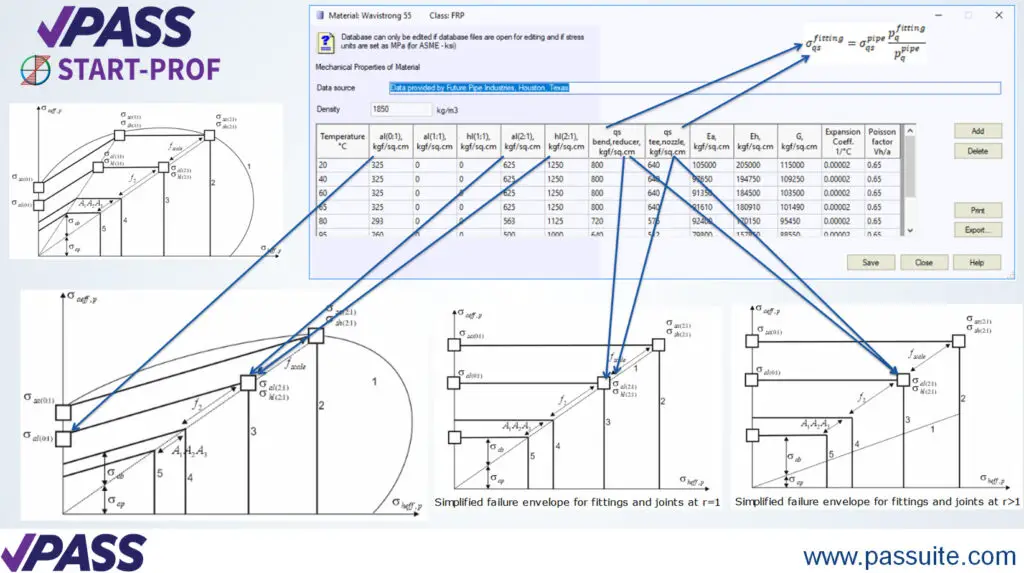

The material is orthotropic. The stress values in axial as well as hoop direction need to be considered during analysis. Mechanical properties needed for analysis differ from steel piping: Ea – Elasticity modulus in the axial direction, Eh – Elasticity modulus in the hoop direction, G – Shear modulus, vh/a – Poisson ratio hoop/axial, va/h – Poisson ratio axial/hoop. Material properties are different for each vendor, so please ask the manufacturer for the values needed for stress analysis in the database.

Linear expansion for GRP / GRE / FRP piping is much greater than for steel piping. Pressure elongation is significant (Bourdon effect), and thermal expansion is also great. Due to uneven heating of pipe wall thickness, the real thermal expansion is lower than thermal expansion for the full temperature range. To consider this piping behavior thermal expansion is multiplied by the temperature range factor which is usually considered 0.85.

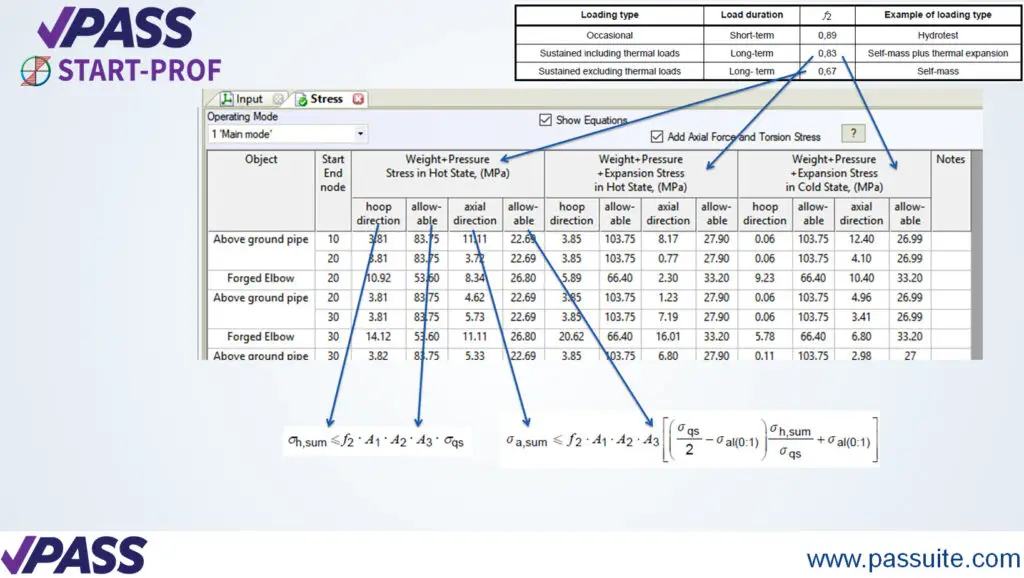

A long-term failure envelope is used instead of single allowable stress. See the material database for more details. Allowable stresses depend on load type factor f2, temperature factor A1, chemical resistance factor A2, and fatigue factor A3. A different envelope is used for pipes and fittings.

Modeling of GRP / GRE / FRP / Reinforced HDPE Piping using PASS/Start-Prof

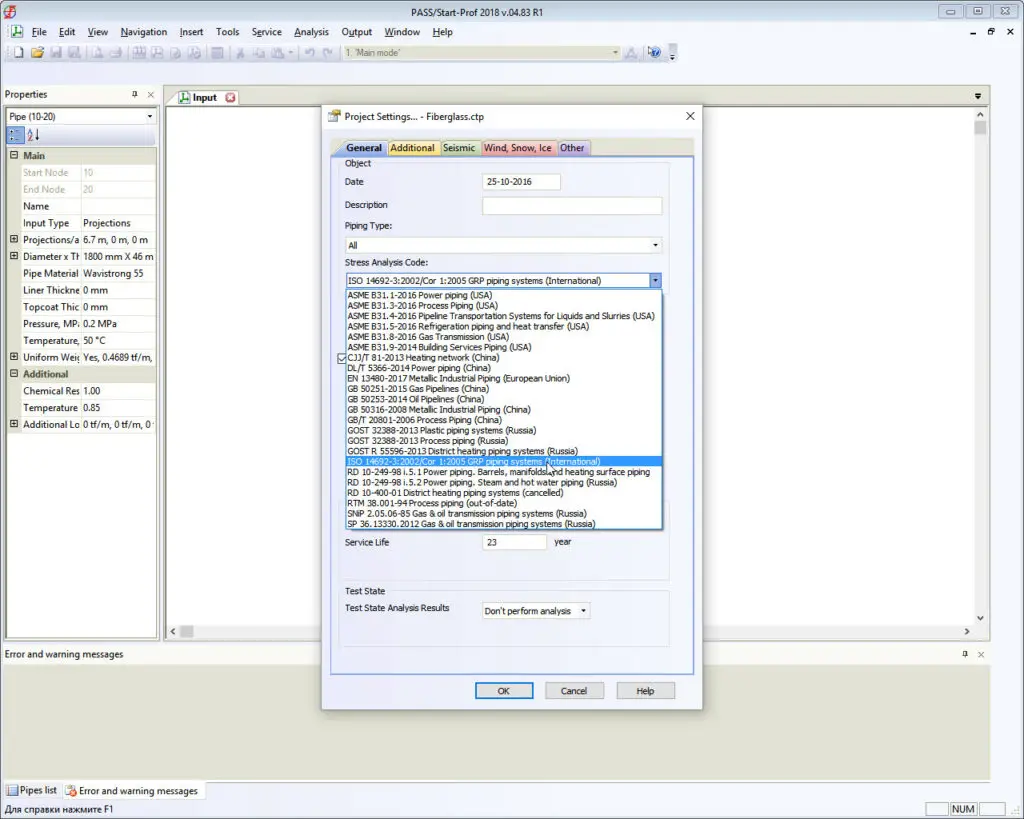

To model GRP / GRE / FRP piping choose ISO 14692 code. This code is also suitable for modeling reinforced HDPE or other plastic piping:

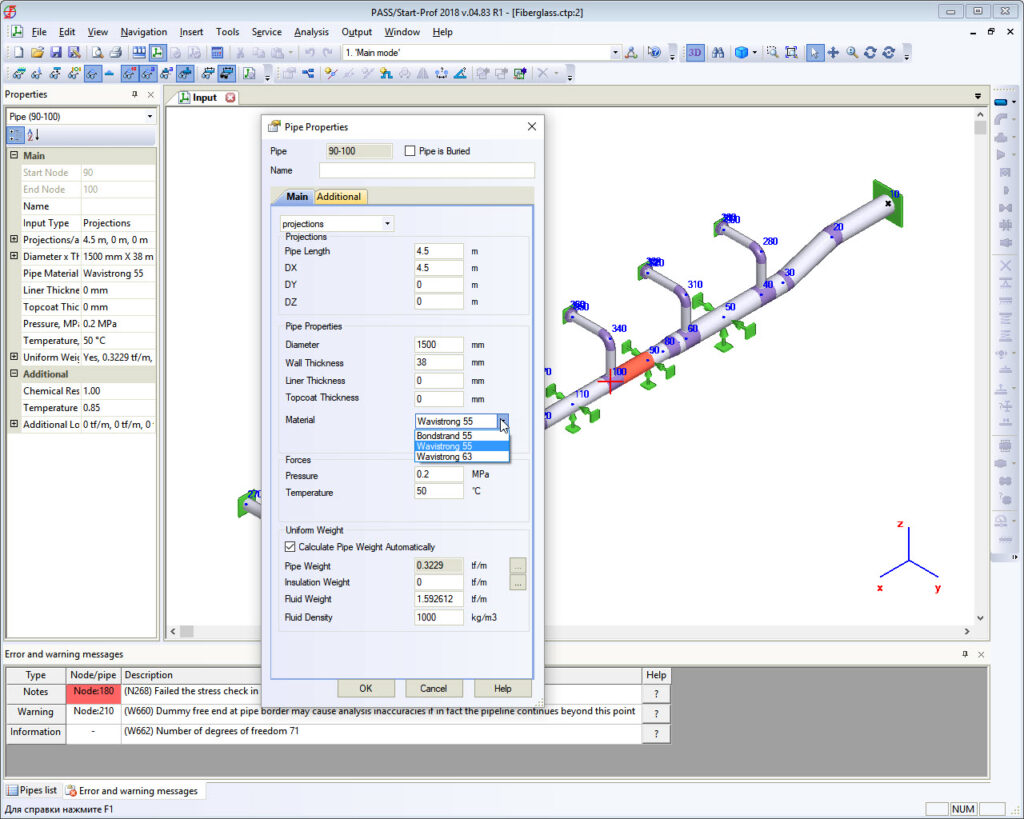

Then select material from the database:

That’s all. All other job is the same as steel piping.

The material Database contains all material properties. If there’s no material you need in the database, please ask your vendor to fill the table and add it to the database manually. Future pipe industries and NOV already provided needed data and it is included in the START-PROF database.

All load cases for the ISO 14692 code will be created automatically. Just draw piping. After analysis, you get results according to ISO 14692 code.

Also, we did a job for the vendor of MRPP pipes to add material properties into the START-PROF database for 50-year service life, and now START-PROF is used for stress analysis of MRPP piping.

MRPP – an HDPE pipe, reinforced by a rigid steel carcass made of a welded wire.

Stress Analysis Methodology

The complete video explaining the stress analysis methodology using Start/Prof is given below for your quick reference.

Download the FRP piping example file. See how to open the piping model file.

Online Video Course of FRP/GRP/GRE Pipeline Stress Analysis using Caesar II

If you are interested in learning FRP/GRE/GRP Piping Stress Analysis using Caesar II software, you can have a look at the following online video course

we are interested