In this article, we will compare START-PROF and Caesar II functions. In START-PROF all pipes, fittings, and nodes are objects. Each object has its properties. For example, you can place bend objects into node objects. You can place a pipe or rigid element between two node objects. You can place bend, tee, reducer, valve, and flange objects into node objects.

Material Database

The material database contains the flag “maximum f=1.2” for materials where it can be applied.

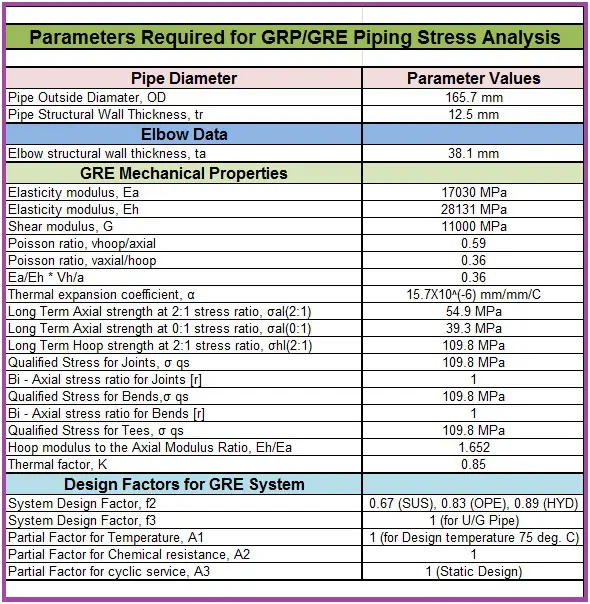

FRP/GRP/GRE Material Properties

A3 and System design factors are calculated automatically where needed. al() and hl() already multiplied by temperature factor A1 in the database. All material properties are stored in the material database, and all pipe and fitting properties are stored in the pipe and fitting dialog windows.

The database contains all data needed for FRP/GRP/GRE analysis. Just select the material and then work like it’s steel piping. See Video about FRP/GRP/GRE stress analysis.

HDPE Material Properties

No analog in Caesar II. The database contains all data needed for the HDPE piping analysis. Just select the material and then work like it’s steel piping. See Video about the HDPE piping analysis.

Pipe Modeling

Different temperatures, pressures, etc. (see “L” button) can be different in different operation modes. Pipe uniform weight can be calculated depending on material density. Weld quality factors W got from the database automatically.

Start to consider high pressure for ASME B31.3-2016 Ch.IX automatically (different wall thickness check, occasion load factor k=1.2, different allowable calculation), not just removing liberal stress.

Additional properties of the pipe looks different depending on the selected code. Here shown B31.1, B31.4, B31.8, ISO 14692, Plastic Piping:

Bends Modeling

START-PROF shows SIF and k-factors for all fittings (bends, tees, reducers, joints) right in the fitting properties dialog box and in the stress table

Elbow Modeling

By default, all bend properties got from the matching pipe. But you can change its material, weight, wall thickness, etc.

ASME B16.9 and all ASME B31 codes don’t regulate the bend, tee, and reducer wall thickness. Only the pipe wall thickness is regulated. So many people think that the elbows and other fittings have the same or almost the same wall thickness as the matching pipe. But in most cases, the real bend, tee, reducer body wall thickness is greater than the matching pipe wall thickness with the same Schedule.

For elbows, the real wall thickness can be 10%-40% greater than the matching pipe. Because bends must have greater wall thickness to hold the same pressure as the connected straight pipe.

Manufacturers usually produce the bends with a greater wall thickness than matching pipe, but we can get real bend wall thickness only after contacting the manufacturer or even measuring it after delivery.

According to the ASME B31 and other ASME B31-based codes bend flexibility factor depends on real bend wall thickness, not on matching pipe wall thickness.

To solve this problem we added a special feature in PASS/START-PROF software that allows calculating the approximate “real” bend wall thickness on the fly according to ASME B31.3 304.2.1 and the same requirements in other ASME B31 and EN 13480 codes. Just push the button “C” near the “Wall Thickness” field and it will be calculated according to the code requirements.

Miter Bends

Non-Standard Bends

For non-standard bends, the user can apply SIFs and k-factors manually.

Other Bends

No analog of such elements in Caesar II

- Long radius bend – section manufactured through pipe bending using a large radius, usually R>40DN. Does not have initial forces and stresses. Used in long pipelines

- Prestressed long radius bend – elastically bent pipe section with a large radius of R>1000DN (natural curve). Unlike a big radius bend, an elastic bend has initial stress. Used in long pipelines

- Miter joint (widely spaced miter bend) – single miter joint that is used for modeling the widely spaced miter bends of a standalone element

Plastic/FRP Bends

Tees

Welding Tee

The START-PROF tee model is complex and contains internal hidden nodes. The tee run is automatically modeled as the pipe with a wall thickness that can be greater than the connected pipe (tn). That’s why START-PROF has “L” and “H” fields. Flexible connections are inserted on the header and branch if needed (if the user selected ASME B31J code or ASME BPV SIII div 1 class 1 NB 3686 method). No side software is needed to use ASME B31J, it’s embedded.

1 – rigid element, 2 – tee header with user-specified wall thickness,

3 – pipe connected to tee header with a different wall thickness

SIF and k-factors are calculated automatically for all standard tees.

Fabricated Tee, Stub-in

Non-Standard Tee

For non-standard tees, the user can specify SIF and k-factors for header and branch: out-of-plane, in-plane, torsion, and axial.

Weldolet, Sweepolet, Extruded

Each type of tee has only the properties that are needed for analysis according to the selected code.

Plastic/FRP Tee

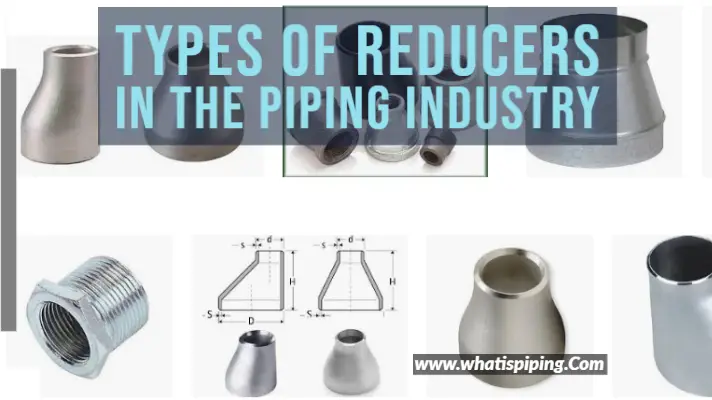

Reducers

Concentric Reducer, Eccentric Reducer

A reducer is a node object, not a pipe element. You can delete it and the geometry will not be changed.

Other Elements

Joints

Valves

A valve is a node object. Not pipe. You can delete it and geometry will not be changed. Modeled as a rigid element with specified weight.

Rigid Element

A rigid element is a “special” pipe object

Ballasting Weight

It is a special object used for modeling ballasting on underwater buried pipelines.

Flange Pair

Flange pair modeled as a rigid element. A leakage check can be done.

Restraints

START-PROF has several “standard” supports that are most often used. And “Nonstandard Restraint” for everything else. Also, START-PROF allows specifying allowable loads. If the support load is greater than allowable the table cell will be colored red and warning messages appear in the errors and warnings window.

Sliding Support:

Guide Support:

START-PROF Guide support consists of vertical and horizontal restraints. Allow setting the gap and friction factor. Allows to define allowable loads

Variable Spring Hanger/Support

The hanger table for spring selection is defined in project settings. START-PROF has a variable spring database that contains springs from several manufacturers. The database will be expanded in the future.

START-PROF has two types of springs: Hangers and Supports. Rod lengths can be specified for hangers and friction factors for supports. If the operation load or stiffness will be left blank, the software will select it automatically. During selection, the software suggests when spring should be replaced by constant spring. After replacement, it will be selected automatically. But the designer should make a decision because constant springs are more expensive.

Constant Spring Hanger/Support

START-PROF has a constant spring database and allows to the selection of correct springs automatically. If vertical force is left blank, then it will be selected

Anchor

Hinged Anchor

Hinged Anchor is used to cut the model into separate parts and for some other purposes. Allows to define allowable loads

Rigid Hanger/Stand

Non-Standard Restraint

Non-standard restraint allows you to create any type of restraint

Loads

Node Forces/Moments

START-PROF has a slightly different ideology based on Operation Mode Editor ideology.

Additional weight loads are used for all operation modes cases including seismic.

Non-weight loads are used for all operation modes excluding seismic.

Additional force-based loads are used only in specified load cases, that is usually occasional (relief valve, water hammer, slug flow, etc.).

Uniform Loads

Uniform loads have the same ideology as node loads, see above. Loads in G’s are automatically calculated in START-PROF by a static seismic load generator.

Displacements

In START-PROF no need to create CNODE and connect the node with displacements. Just add the anchor and add the “deformation” into it.

Expansion Joints:

Complex expansion joint models can be created in START-PROF, but it is not needed. START-PROF has standard expansion joint models. Allowable axial, rotation and lateral deformation are checked by the software automatically. The expansion joint report is shown below:

Axial Bellows:

START-PROF has expansion joint database

Axial Slip Joint:

Axial One-time Compensator

This type of expansion joint is widely used in buried district heating networks to perform the cold spring effects.

Gimbal:

Lateral:

Non-Standard:

Wind, Show, Ice, Seismic, Wave Loads:

Wind, Snow, and Ice Loads:

Wind, Snow, and Ice loads can be generated automatically. No Snow and Ice loads generator in Caesar II

Seismic Loads:

Wave Loads:

There are no wave loads in START-PROF yet.

Load Case Editor = Operation Mode Editor:

START-PROF has a high-level Operation Mode Editor, based on templates. That allows doing the same things as Load Case Editor but in a more fast and easy to understand manner.

Other Features:

START-PROF always considers Bourdon Effect (Translation & Rotation). The occasional load factor is taken according to the selected code and chosen in the operation mode editor. The SIF multiplier for sustained stress is always according to the selected code.

See ASME B31.3 302.3.5 equation (1с). If selected, then the maximum value of stress range factor f can be 1.2 for materials with the enabled option “Maximum f=1.2” in the material database, otherwise, the maximum value always f=1.0.

ASME B31J:

To use more accurate SIF and k-factors just turn on this switch (see below). All calculations and model modifications will be done automatically on-the-fly. No need to use any additional software (B31J Essentials, FEATools).

Units Convention:

Units can be converted at any time on-the-fly. Before analysis, and after analysis. No need to convert the whole model.

Underground (Buried) Piping Analysis:

See Video about buried piping analysis with START-PROF.

There’s no underground pipe modeler in START-PROF. The Soil springs are added automatically each time you run an analysis. You can change the model and run analysis immediately, no need to open a backup copy of the model without soil springs and run an underground pipe modeler again. START-PROF is very fast and easy.

Creep in High-Temperature Piping:

Creep Effect (stress relaxation and self-cold-springing effect) is considered for high-temperature piping in START-PROF. Not just for operating mode, but also for cold mode. The cold mode is the most dangerous for high-temperature piping due to the self-cold springing effect.

Wall Thickness Check:

START-PROF has a special module START-ELEMENTS that allows checking of wall thickness or allowable pressure for pipes, bends, tees, reducers, caps, and flanges. Also before piping analysis START-PROF checks the wall thickness of all pipes and fittings to satisfy pressure requirements for all operating modes.

Pipe Stability (Buckling) Analysis:

START-PROF has several functions to analyze different types of buckling: Upheaval Buckling of Buried Pipeline, Upheaval Buckling of Buried Long-radius Bend, Lateral Buckling of Above-ground Pipe, Vacuum Piping Local Wall Buckling due to external pressure and due to external pressure, axial force and moment

Convergence Problems:

START-PROF has no problems with Iterative convergence. There are no settings that the user must change to achieve convergence. Everything is done automatically.

User Interface Functions:

You can change the properties of one object or group of objects very easily. You can select a part of piping and copy & paste, mirror, rotate, split it. Insert node on the pipe or bend, Move along the pipe or bend node, delete node(just select node, and click DEL button).

You can easily change the properties of multiple objects (bends, tees, pipes, etc.) using the properties float window. START-PROF has all the needed functions to work with independent piping segments.

Analysis result reports are smart and interactive: Code Stress Report, Spring Selection Report, Expansion Joint Report, Flange Leakage Report, Insulation Stress Report, Internal Forces, Support Loads Report, Local Wall Buckling Report, and Node Displacements Report. All reports can be exported into Excel, Word, txt, and HTML.

START-PROF has a smart errors and warnings window that all engineering warnings: Pressure failure, buckling failure, support lift off, Spring hanger variable range >25%, spring hanger load greater than allowable in all operating modes, sustained or fatigue stress failure, etc. Not just only stress failure.

Graphic deformation shows hot/cold and install position, deformation position is simple and easy to understand by end users.

Project Tree:

In the project tree, you can see the temperatures, pressures, etc, color diagram, select the needed group of an object and change its properties, delete, copy, etc. Also in START-PROF, you can see all other object properties like bends, tees, reducers, etc.

PDMS Interface:

START-PROF has free PDMS and E3D interface: See Video