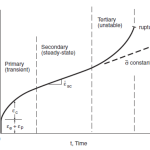

Shear Modulus is defined as the ratio of shear stress to the corresponding shear strain within a material’s proportional limit. Also known as modulus of rigidity and rigidity modulus, the shear modulus is denoted by “G” and can be experimentally determined from the slope of the shear stress (τ) vs shear strain (γ) curve. The more the value of the shear modulus or modulus of rigidity, the more rigid the material is. The shear modulus values of engineering materials are determined by torsional tests. It is a measure of a material’s resistance to deformation under shear stress.

Shear Modulus Units

The SI unit of modulus of rigidity or shear modulus is the Pascal (Pa). However, it is popularly expressed in gigapascals (GPa). The unit of shear modulus in the English system is a thousand pounds per square inch (KSI). Its dimensional form is M1L−1T−2.

Shear Modulus Formula

On the application of a shear force on a body, it deforms laterally. So, the shear modulus is basically a measure of the material’s ability to resist transverse deformation. Large shear forces can create a flow in the material. Mathematically, the formula for shear modulus can be expressed as follows:

Shear Modulus, G=Shear Stress (τ)/Shear Strain (γ)

Now Shear stress= Shear Force (F)/ Area (A) and Shear Strain= Change in Length (Δ) in the lateral direction/Original length(L). Hence

The formula for Shear Modulus, G=FL/AΔ

The relationship of Shear Modulus (G) with Young’s modulus (E) and Poisson’s ratio (μ) is given below:

E=2G(1+μ) or G = E/(2(1+μ)

Characteristics of Shear Modulus or Modulus of Rigidity

- Modulus of rigidity is a material property and remains constant for a material at a specific temperature.

- The shear modulus is independent of the geometry of the material.

- With an increase in temperature, the modulus of rigidity decreases.

- A high value of modulus of rigidity means it will maintain its shape and a large force will be required to deform it, and a low value of shear modulus signifies the material is soft or flexible.

- Fluids (Liquids and Gases) have the minimum value of rigidity modulus (0) and they started flowing with a little application of shear force.

- Diamond has the maximum value of shear modulus (478 GPa).

- Shear Strength is the maximum value of shear stress that a material can withstand without fracture or failure.

Shear Modulus of Steel and Other Materials

The shear modulus of carbon steel is 77 GPa and the same for stainless steel is 77.2 GPa. The modulus of rigidity of water is considered zero. The modulus of rigidity values at room temperature for other common materials are tabulated below:

| Material | Shear Modulus or Modulus of Rigidity in GPa | Material | Shear Modulus or Modulus of Rigidity in GPa |

| Aluminum Alloys | 25-27 | Tin | 18 |

| Aluminum | 24-28 | Titanium, Grade 2 | 41 |

| Beryllium Copper | 48 | Titanium, Grade 5 | 41 |

| Brass | 40 | Titanium, 10% Vanadium | 42 |

| Bronze | 44.8 | Tungsten | 161 |

| Cadmium | 19 | Wood, Douglas Fir | 13 |

| Nickel | 76 | Zinc | 43 |

| Cast Iron | 41 | Z-nickel | 76 |

| Chromium | 115 | Steel, Cast | 78 |

| Concrete | 21 | Steel, Cold-rolled | 75 |

| Copper | 45 | Plywood | 0.62 |

| Glass | 26.2 | Polycarbonate | 2.3 |

| Glass, 96% silica | 19 | Polyethylene | 0.12 |

| Inconel | 79 | Rubber | 0.0006 |

| Iron, Ductile | 63 – 66 | Structural Steel | 79.3 |

| Iron, Malleable | 64 | Monel metal | 66 |

| Kevlar | 19 | Nickel Silver | 48 |

| Lead | 13.1 | Nickel Steel | 76 |

| Magnesium | 16.5 | Nylon | 4.1 |

| Molybdenum | 118 | Phosphor Bronze | 41 |

| Diamond | 478 | Wood | 4 |

| Chalk | 3.2 | Granite | 24 |

Importance of Shear Modulus in Engineering

Modulus of Rigidity or Shear Modulus plays a crucial role in various engineering applications, particularly in structural and mechanical engineering. Here are some key reasons why the shear modulus is important:

- Material Strength: The shear modulus is an indicator of a material’s strength and stiffness under shear loading conditions. Materials with higher shear modulus values are generally stronger and more resistant to deformation when subjected to shear stress. This property is essential in designing structures and components that can withstand applied loads without failure.

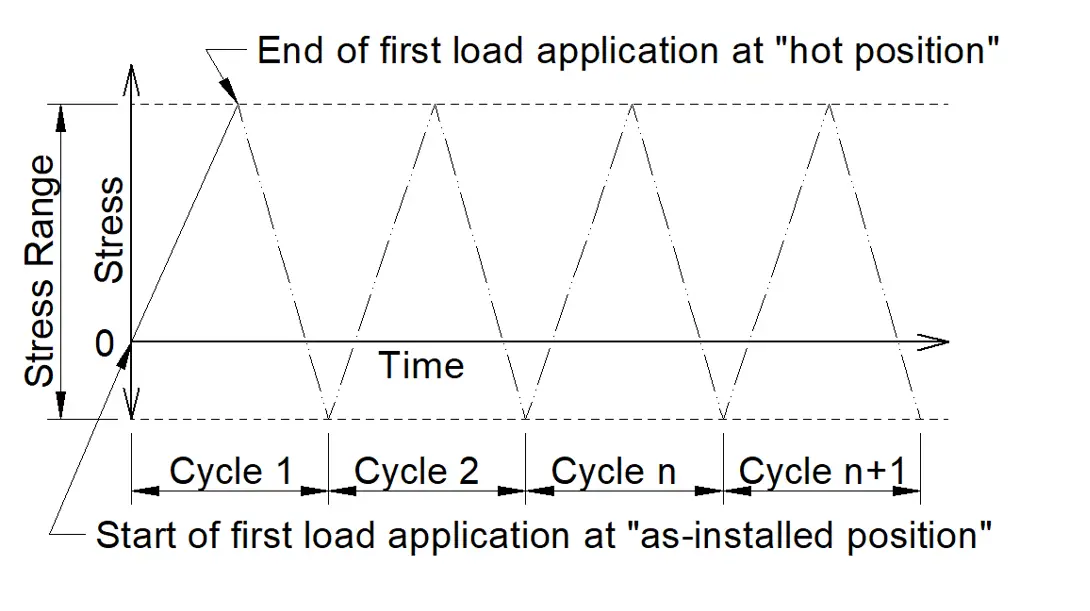

- Elastic Deformation: The shear modulus determines the amount of elastic deformation a material undergoes when subjected to shear stress. It defines the relationship between shear stress and shear strain in the elastic region of the material’s stress-strain curve. Understanding this relationship is critical for predicting the behavior of materials under loading conditions and ensuring that structures remain within their elastic limits to avoid permanent deformation.

- Material Selection: Engineers use the shear modulus to compare the mechanical properties of different materials and select the most suitable material for a particular application. For example, in the design of mechanical components, choosing materials with appropriate shear modulus values can ensure that the components meet performance requirements while minimizing weight and cost.

- Structural Analysis: The shear modulus is essential in structural analysis and design, particularly in determining the stiffness and stability of various structural elements, such as beams, columns, and shafts. It influences parameters such as deflection, bending stress, and torsional rigidity, which are critical considerations in the design of safe and efficient structures.

- Material Behavior Prediction: Knowledge of the shear modulus allows engineers to predict how materials will respond to different types of loading, including shear, torsion, and bending. This information is invaluable in designing structures and components that can withstand various types of mechanical stresses encountered during operation.

- Material Characterization: The shear modulus is a key parameter used in material characterization and testing. Experimental techniques such as torsion testing and shear wave propagation methods are employed to measure the shear modulus of materials accurately. These measurements provide valuable data for material selection, quality control, and research purposes.

Differences between Shear Modulus and Young’s Modulus

Both Young’s modulus and shear modulus are measures of a material’s stiffness, they apply to different types of stress and deformation. Young’s modulus is concerned with linear deformation under tensile or compressive stress, whereas shear modulus is concerned with angular deformation under shear stress.

Here’s a tabulated summary highlighting the main differences between Young’s modulus (also known as the modulus of elasticity in tension or compression) and shear modulus (also known as the modulus of rigidity):

| Aspect | Young’s Modulus | Shear Modulus |

|---|---|---|

| Definition | Measure of a material’s resistance to linear deformation under tensile or compressive stress | Measure of a material’s resistance to shear deformation under shear stress |

| Symbol | E | G or S |

| Types of Stress | Tensile or Compressive Stress | Shear Stress |

| Types of Deformation | Linear (stretching or compressing) | Angular (twisting or shearing) |

| Formula | 𝐸=StressStrainE=StrainStress | 𝐺=Shear StressShear StrainG=Shear StrainShear Stress |

| Units | Pascals (Pa) | Pascals (Pa) |

| Material Behavior | Reflects resistance to stretching or compressing | Reflects resistance to shearing or twisting |

| Application | Used in the design and analysis of structures under tensile or compressive loads | Used in the design and analysis of structures under shear loads |

If you still have doubts about shear modulus or rigidity modulus, then I recommend the following video lecture: