In my last article on stress analysis of tank piping, I described the effect of tank bulging. Click here to refresh yourself on the effect of storage tank bulging. In this article, I will describe the effect of storage tank settlement on stress analysis of piping systems connected to large tanks.

Why does settlement occurs for tanks but not for other equipment?

Other equipment’s diameter is usually small (up to 3m). Therefore it is possible to design its foundation with large rafts (say 10 m) to minimize or have an insignificant settlement.

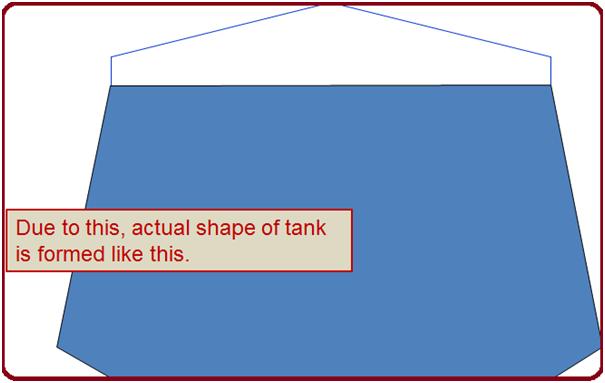

Whereas storage tank diameters are generally large, of the order of 10 m to 60 m. Due to this, it is impractical to design its foundation with a raft, which would be much bigger than this. Many times it has a ring foundation with soil compacted within this concrete ring.

How much settlement is to be considered?

The amount of settlement depends on the location of the tank. The amount of settlement is normally mentioned in the soil investigation reports or geo-technological investigation reports.

IN THE CASE OF SAND:

The majority of the total settlement occurs during the hydrostatic test of the tank (before the piping is connected). This is generally permanent.

… Typically 60%

The balance of 40% of the settlement, occurs after the piping is connected to the storage tank nozzle. And the piping system needs to be designed properly with this settlement effect.

IN THE CASE OF CLAY:

Progressive settlement.

The settlement is more at the center of the storage tank, and typically 50% at the edge of the tank.

Since our nozzles and tank roof are connected/supported on the shell, which is on the outer edge of the atmospheric storage tank, we need to consider the settlement at the outer edge of the tank.

Following Data to be obtained from civil for each tank (for each project)

- Total long-term settlement.

- The settlement value that will occur during the construction and hydro test of the tank.

- Recovery (if any) following construction and hydro test of the tank.

- The further settlement, after the hydro test of the tank, (at the edge of the tank).

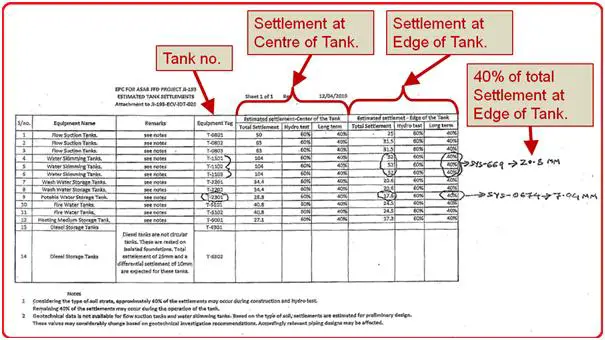

Sample Data from civil for each tank for a typical project is shown in Fig. 1 for understanding.

- It contains each Tank number.

- Settlement at the Centre of the Tank.

- Settlement at Edge of Tank.

Then out of the total settlement at Edge, 40% of the total settlement is what we consider in piping stress analysis.

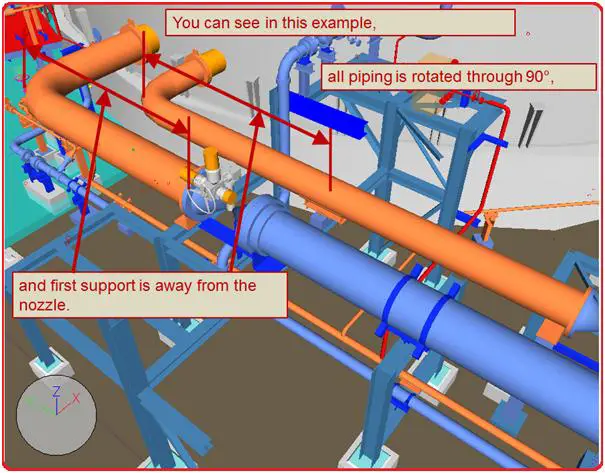

Pipe routing guidelines (Fig. 2) to minimize the effect of tank settlement:

To reduce the effect of tank settlement on piping:

- First support shall be kept sufficiently away from the tank nozzle.

- Large-diameter piping combined with large tank settlement may call for use of spring support.

However, the use of spring support shall be avoided because accidental draining of the line will cause an excessive upward force on the piping and tank nozzle.

So, if spring support is used

- WNC (Weight with No Content) load case shall be mandatory for liquid lines. In fact, for all liquid lines with spring support, (whether it is connected to the tank or any other line), a WNC run shall be mandatory. In the case of the tank, all lines connected to the tank will be carrying liquid only.

- The spring hanger setting should be adjusted in such a way, that the nozzle load is within the limit in the normal operating case, as well as in the WNC case.

- That is set spring support for loads lower than what is required. This will increase the nozzle load in the normal operating case but will reduce the load in the WNC case.

Click here to learn about storage tank piping layout considerations.

how to include buldging and settlement in caesar ii.

Currently I work in tank farm project. Is it safe to hydrotest the tank with piping connected to tank nozzle with line blind. We considered 25mm settlement during design. In order to reduce idle man hours by subcon our company asking engineering to confirm if possible or not. Thanks in advance.

Very good