A thermocouple is a type of temperature sensor that measures temperature through the voltage generated when two different metals are joined together. The two metals are usually referred to as thermoelements, and they are typically made of different types of metals or alloys, such as copper and constantan, or iron and constantan.

When one end of the thermocouple is exposed to a higher temperature than the other, a temperature gradient is created across the two thermoelements, causing a voltage to be generated. This voltage is proportional to the temperature difference between the two ends of the thermocouple and can be measured with a voltmeter.

Thermocouples are commonly used in industrial applications to measure temperature in harsh environments, such as high-temperature furnaces, where other types of temperature sensors may fail. They are also used in household appliances like ovens and water heaters.

Applications of a Thermocouple

Thermocouples have a wide range of applications across various industries, including:

- Temperature measurement in industrial processes: Thermocouples are commonly used for temperature measurement in a wide range of industrial processes, including metallurgy, power generation, chemical processing, and food processing.

- Automotive industry: Thermocouples are used in automotive engines to monitor temperature and ensure that the engine is operating at the correct temperature range.

- Aerospace industry: Thermocouples are used in aircraft engines, rockets, and space vehicles to monitor temperature and ensure that critical components are not overheating.

- Medical equipment: Thermocouples are used in medical equipment to monitor the temperature of patients during surgery, and to measure the temperature of incubators for newborns.

- Household appliances: Thermocouples are used in gas-powered household appliances, such as ovens, water heaters, and furnaces, to monitor temperature and ensure safe operation.

- Environmental monitoring: Thermocouples are used in weather stations and environmental monitoring equipment to measure temperature in the air, water, and soil.

Other applications include

- Food Production

- Extruders

- Furnace

- Gas Appliances

- High-Pressure Boiler

Overall, thermocouples are widely used because of their durability, accuracy, and ability to measure temperature in harsh environments.

How Does a Thermocouple Work?

A thermocouple works on the principle of the Seebeck effect, which states that when two different metals are joined together at two different temperatures, a voltage is produced that is proportional to the temperature difference.

A thermocouple consists of two dissimilar metal wires, or thermoelements, that are joined at one end to form a junction. When the junction is exposed to a temperature difference, a voltage is generated across the length of the thermocouple wire. This voltage is measured using a voltmeter and is related to the temperature difference between the hot and cold junctions by a mathematical formula that varies depending on the types of metals used in the thermocouple.

The accuracy of a thermocouple depends on several factors, including the types of metals used, the temperature range being measured, and the sensitivity of the measuring instrument. To improve accuracy, the thermocouple wires are typically calibrated against a known temperature reference.

Thermocouples are commonly used in industrial applications where they need to operate in high-temperature environments, such as furnaces, kilns, and gas turbines. They are also used in household appliances, such as ovens and water heaters, to monitor temperature and ensure safe operation.

Selection of a Thermocouple

Selecting the right thermocouple for a specific application depends on several factors, including the temperature range of the application, the environment in which the thermocouple will be used, the accuracy required, and the cost.

Here are some important considerations to help select a thermocouple for a specific application:

- Temperature range: The temperature range of the application will determine which types of thermocouples are suitable. For example, Type K thermocouples can measure temperatures up to 1,200°C, while Type S thermocouples can measure temperatures up to 1,600°C.

- Environmental conditions: The environment in which the thermocouple will be used is also an important consideration. For example, if the thermocouple will be exposed to corrosive materials or moisture, a thermocouple with a protective sheath may be needed.

- Accuracy requirements: The level of accuracy required for the application will also determine which type of thermocouple is suitable. For applications that require high accuracy, a Type R or Type S thermocouple may be necessary.

- Response time: The response time of the thermocouple is important in applications where temperature changes rapidly. For example, a fast-responding thermocouple may be necessary for a furnace where the temperature changes quickly.

- Cost: The cost of the thermocouple is also an important consideration. Some types of thermocouples are more expensive than others, so the cost must be balanced against the other factors when selecting a thermocouple for a specific application.

Overall, selecting the right thermocouple for a specific application requires careful consideration of several factors. Consulting with a thermocouple supplier or manufacturer can help ensure that the best thermocouple is selected for the application.

Components of a Thermocouple

The main components of a thermocouple are:

- Thermoelements: These are the two dissimilar metal wires that are joined together at one end to form the measuring junction of the thermocouple. The thermoelements generate a voltage that is proportional to the temperature difference between the hot and cold junctions.

- Protective sheath: This is an optional component that encloses the thermoelements and protects them from the environment. The sheath can be made of a variety of materials depending on the application, such as stainless steel, Inconel, or ceramic.

- Connection head: This is the enclosure that connects the thermocouple to the instrumentation. It is usually made of aluminum or cast iron and provides a terminal block for connecting the thermocouple wires to the instrumentation wires.

- Extension wires: These are the wires that connect the thermocouple to the measuring instrument. The wires are made of the same materials as the thermocouple thermoelements but can be less expensive and less accurate than the thermocouple itself.

- Measuring instrument: This is the device that measures the voltage generated by the thermocouple and converts it into a temperature reading. The measuring instrument can be a digital multimeter, a temperature controller, or a data logger, depending on the application.

Overall, the components of a thermocouple work together to accurately measure temperature in a variety of industrial and scientific applications.

Types of Thermocouples

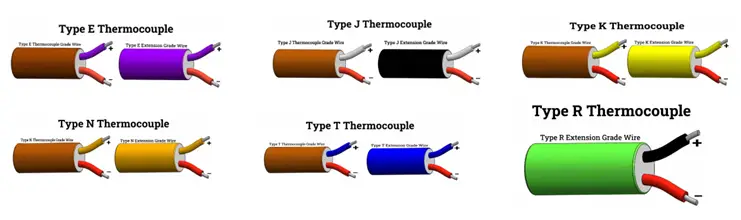

There are several types of thermocouples, each with different temperature ranges and characteristics. The most common types of thermocouples (Refer to Fig. 1 below) are:

Type K Thermocouple

Type K thermocouple is a type of thermocouple that is commonly used for temperature measurement in a variety of applications. It consists of two wires made of different alloys, chromel (90% nickel and 10% chromium) and alumel (95% nickel, 2% manganese, 2% aluminum, and 1% silicon), that are joined together at one end to form a junction. The junction is typically enclosed in a protective sheath made of metal or ceramic material.

Type K thermocouples have a wide temperature range of approximately -200°C to 1,372°C (-328°F to 2,502°F) and are commonly used in applications such as furnace and oven temperature control, gas turbine exhaust monitoring, and in the automotive industry. They have a sensitivity of approximately 41 µV/°C and are known for their high accuracy and stability over a wide temperature range.

One of the advantages of Type K thermocouples is their low cost and widespread availability, which makes them a popular choice for many industrial and scientific applications. However, they may not be suitable for use in certain extreme environments, such as high-temperature applications above 1,000°C (1,832°F), or in corrosive or high-pressure environments, where other types of thermocouples may be more suitable.

Type J Thermocouple

Type J thermocouple is a type of thermocouple that is commonly used for temperature measurement in a variety of applications. It consists of two wires made of different alloys, iron, and constantan (55% copper and 45% nickel), that are joined together at one end to form a junction. The junction is typically enclosed in a protective sheath made of metal or ceramic material.

Type J thermocouples have a temperature range of approximately -210°C to 760°C (-346°F to 1,400°F) and are commonly used in applications such as food processing, industrial heating and cooling, and scientific research. They have a sensitivity of approximately 50 µV/°C and are known for their high accuracy and stability over a wide temperature range.

One of the advantages of Type J thermocouples is their high output voltage, which makes them a popular choice for low-temperature applications such as cryogenics and refrigeration. They are also resistant to oxidation and have a long lifespan, making them a reliable choice for many industrial and scientific applications.

The color coding for Type J thermocouples is white for the positive wire and red for the negative wire. It is important to note that the color coding for thermocouples may vary slightly depending on the country or region, and it is recommended to refer to the manufacturer’s documentation or industry standards to ensure proper identification and use of the thermocouple.

Type T Thermocouple

This thermocouple is suitable for use in low-temperature applications, with a temperature range of -270°C to +400°C. It has good accuracy but is less commonly used than Type K and Type J.

Type T thermocouples have a temperature range of approximately -270°C to 400°C (-454°F to 752°F) and are commonly used in applications such as cryogenics, food processing, and pharmaceutical industries. They have a sensitivity of approximately 43 µV/°C and are known for their high accuracy and stability over a wide temperature range.

One of the advantages of Type T thermocouples is their high stability and low drift, making them a popular choice for high-precision temperature measurements. They are also relatively immune to the effects of thermal shock, vibration, and corrosion, making them a reliable choice for many industrial and scientific applications.

The color coding for Type T thermocouples is blue for the positive wire and red for the negative wire. It is important to note that the color coding for thermocouples may vary slightly depending on the country or region, and it is recommended to refer to the manufacturer’s documentation or industry standards to ensure proper identification and use of the thermocouple.

Type E Thermocouple

Type E thermocouple is a type of thermocouple that is commonly used for temperature measurement in a variety of applications. It consists of two wires made of different alloys, chromel (90% nickel and 10% chromium) and constantan (55% copper and 45% nickel), that are joined together at one end to form a junction. The junction is typically enclosed in a protective sheath made of metal or ceramic material.

Type E thermocouples have a temperature range of approximately -270°C to 1,000°C (-454°F to 1,832°F) and are commonly used in applications such as food processing, scientific research, and environmental monitoring. They have a sensitivity of approximately 68 µV/°C and are known for their high accuracy and stability over a wide temperature range.

One of the advantages of Type E thermocouples is their high accuracy at low temperatures, which makes them a popular choice for low-temperature applications such as cryogenics and refrigeration. They are also resistant to oxidation and have a long lifespan, making them a reliable choice for many industrial and scientific applications.

The color coding for Type E thermocouples is purple for the positive wire and red for the negative wire. It is important to note that the color coding for thermocouples may vary slightly depending on the country or region, and it is recommended to refer to the manufacturer’s documentation or industry standards to ensure proper identification and use of the thermocouple.

Type N Thermocouple

This thermocouple is suitable for use in high-temperature applications. It has good accuracy and is often used in aerospace and nuclear applications. It consists of two wires made of different alloys, Nicrosil (84% nickel, 14.2% chromium, and 1.4% silicon) and Nisil (95% nickel and 5% silicon), that are joined together at one end to form a junction. The junction is typically enclosed in a protective sheath made of metal or ceramic material.

Type N thermocouples have a temperature range of approximately -270°C to 1,300°C (-454°F to 2,372°F) and are commonly used in applications such as furnace temperature monitoring, aerospace, and automotive industries. They have a sensitivity of approximately 39 µV/°C and are known for their high accuracy and stability over a wide temperature range.

One of the advantages of Type N thermocouples is their resistance to oxidation at high temperatures, which makes them a popular choice for high-temperature applications. They are also relatively immune to the effects of thermal shock, vibration, and corrosion, making them a reliable choice for many industrial and scientific applications.

The color coding for Type N thermocouples is orange for the positive wire and red for the negative wire. It is important to note that the color coding for thermocouples may vary slightly depending on the country or region, and it is recommended to refer to the manufacturer’s documentation or industry standards to ensure proper identification and use of the thermocouple.

Type R Thermocouple

It consists of two wires made of different alloys, platinum, and rhodium, that are joined together at one end to form a junction. The junction is typically enclosed in a protective sheath made of metal or ceramic material.

Type R thermocouples have a temperature range of approximately 0°C to 1600°C (32°F to 2912°F) and are commonly used in applications such as furnaces, gas turbine exhaust, and other high-temperature environments. They have a sensitivity of approximately 10 µV/°C and are known for their high accuracy and stability over a wide temperature range.

One of the advantages of Type R thermocouples is their high-temperature stability, which makes them suitable for use in harsh and extreme environments. They also have a high resistance to oxidation at high temperatures, which makes them suitable for use in applications where other thermocouples may fail due to oxidation.

The color coding for Type R thermocouples is black for the positive wire and green for the negative wire. It is important to note that the color coding for thermocouples may vary slightly depending on the country or region, and it is recommended to refer to the manufacturer’s documentation or industry standards to ensure proper identification and use of the thermocouple.

Type S Thermocouple

Type S thermocouple is a type of thermocouple that is similar to Type R thermocouple, but is typically used in even higher-temperature applications. It consists of two wires made of different alloys, platinum, and rhodium, that are joined together at one end to form a junction. The junction is typically enclosed in a protective sheath made of metal or ceramic material.

Type S thermocouples have a temperature range of approximately 0°C to 1600°C (32°F to 2912°F) and are commonly used in applications such as aerospace, furnace control, and power plant boilers. They have a sensitivity of approximately 10 µV/°C and are known for their high accuracy and stability over a wide temperature range.

One of the advantages of Type S thermocouples is their high-temperature stability and accuracy, which makes them suitable for use in harsh and extreme environments. They also have a high resistance to oxidation at high temperatures, which makes them suitable for use in applications where other thermocouples may fail due to oxidation.

The color coding for Type S thermocouples is black for the positive wire and orange for the negative wire. It is important to note that the color coding for thermocouples may vary slightly depending on the country or region, and it is recommended to refer to the manufacturer’s documentation or industry standards to ensure proper identification and use of the thermocouple.

Type B Thermocouple

Type B thermocouple is a type of thermocouple that is composed of two different alloys, platinum-rhodium, and platinum-rhodium (30% Rh-6% Rh and 94% Pt-6% Rh), which are joined together to form a junction. This type of thermocouple is commonly used in high-temperature applications, such as in the chemical and petrochemical industries, power plants, and furnaces, where temperatures can exceed 1700°C (3092°F).

Type B thermocouples have a very high-temperature range and are known for their high accuracy and stability at high temperatures. They are also highly resistant to oxidation, which makes them suitable for use in harsh and corrosive environments. However, they are relatively expensive compared to other types of thermocouples, and their sensitivity is lower than other types.

The color coding for Type B thermocouples is white for the positive wire and red for the negative wire. It is important to note that the color coding for thermocouples may vary slightly depending on the country or region, and it is recommended to refer to the manufacturer’s documentation or industry standards to ensure proper identification and use of the thermocouple.

Type C Thermocouple

“Type C” refers to a tungsten-rhenium thermocouple. This type of thermocouple is not commonly used in industrial or commercial applications but is sometimes used in high-temperature research and in laboratory equipment.

Tungsten-rhenium thermocouples have a temperature range of approximately 0°C to 2,300°C (32°F to 4,172°F) and are known for their high accuracy and stability at high temperatures. They are often used in applications such as materials testing, vacuum furnace temperature measurement, and high-temperature research.

The wires of a tungsten-rhenium thermocouple are usually made of tungsten-rhenium alloy and are joined at the measurement junction. The thermocouple wires are often encased in a ceramic or metal sheath for protection. It is important to note that tungsten-rhenium thermocouples are not interchangeable with other types of thermocouples and require special handling and calibration procedures.

Overall, the selection of the appropriate thermocouple type for a particular application depends on several factors, including temperature range, accuracy, and cost.

Color Coding of Thermocouples

Color coding is a standardized method of identifying and distinguishing different types of thermocouples based on the color of the wires used in their construction. The color coding system varies depending on the type of thermocouple but typically consists of a pair of wires, one of which is positive and the other negative. The colors of the wires are used to identify the type of thermocouple, as well as to indicate which wire is positive and which is negative.

Here is a summary of the color coding for some of the most common types of thermocouples:

- Type K: Positive wire: Yellow Negative wire: Red

- Type J: Positive wire: White Negative wire: Red

- Type T: Positive wire: Blue Negative wire: Red

- Type E: Positive wire: Purple Negative wire: Red

- Type R: Positive wire: Orange Negative wire: Green

- Type S: Positive wire: Orange Negative wire: Red

- Type B: Positive wire: Red Negative wire: Blue

It is important to note that the color coding for thermocouples may vary slightly depending on the country or region. It is also recommended to refer to the manufacturer’s documentation or industry standards to ensure proper identification and use of the thermocouple.

Uses of Thermocouples in the Oil and Gas Industry

Thermocouples have several important applications in the oil and gas industry, including:

- Temperature monitoring in refineries: Thermocouples are used to monitor the temperature of various processes in refineries, such as distillation, cracking, and hydrotreating. Accurate temperature measurement is important for optimizing process efficiency and ensuring product quality.

- Downhole temperature measurement: Thermocouples are used in oil and gas wells to monitor the downhole temperature. This information can be used to optimize production and improve recovery rates.

- Gas turbine exhaust temperature monitoring: Thermocouples are used to monitor the exhaust temperature of gas turbines used in oil and gas production. Accurate temperature measurement is important for optimizing turbine efficiency and reducing emissions.

- Oil and gas pipeline temperature monitoring: Thermocouples are used to monitor the temperature of oil and gas pipelines to ensure that the product is flowing within safe temperature limits. This is important for maintaining pipeline integrity and preventing accidents.

- Flare stack temperature monitoring: Thermocouples are used to monitor the temperature of flare stacks used in oil and gas production. Accurate temperature measurement is important for ensuring safe operation and compliance with environmental regulations.

Overall, thermocouples are critical for accurate temperature measurement in various processes and equipment used in the oil and gas industry.

Design Codes and Standards for Thermocouples

There are several design codes and standards that govern the use and design of thermocouples. Some of the most commonly used standards are:

- ASTM E230-03: This standard specifies the tolerances for thermocouple wires, which are used to manufacture thermocouples.

- ASTM E1129: This standard provides guidelines for the calibration of thermocouples, including methods for determining the temperature-emf relationship and the uncertainty associated with the calibration process.

- ANSI/ISA-51.1: This standard provides guidelines for the selection, installation, and use of thermocouples in industrial applications.

- IEC 60584: This standard provides guidelines for the selection, installation, and use of thermocouples in a variety of applications.

- ASME PTC 19.3 TW: This standard provides guidelines for the use of thermocouples in power plant applications, including design, installation, and calibration.

- NIST SP 250-23: This standard provides guidelines for the calibration of thermocouples using fixed-point cells and interpolation techniques.

Overall, the design codes and standards for thermocouples provide guidelines for the selection, installation, calibration, and use of these devices in a variety of industrial and scientific applications. Adhering to these standards helps ensure that thermocouples are accurate, reliable, and safe to use.

Thermocouple Failures

There are several factors that can cause a thermocouple to fail, including:

- Oxidation and corrosion: The thermocouple wires are usually made of different metals, which can corrode or oxidize over time, especially in harsh environments. This can cause a reduction in the thermocouple’s output voltage, leading to inaccurate temperature readings.

- Contamination: If the thermocouple junction or wires are contaminated with foreign materials, such as dirt or oil, this can affect the accuracy of the temperature reading.

- Mechanical stress: If the thermocouple wires or junction are subjected to excessive mechanical stress, such as bending or twisting, this can cause the wires to break or the junction to shift, leading to inaccurate temperature readings.

- High temperatures: If the thermocouple is exposed to temperatures higher than its maximum operating range, this can cause the wires to melt or the insulation to break down, leading to failure.

- Aging: Over time, the thermocouple wires can age and become more brittle, which can cause them to break or degrade, leading to a loss in accuracy.

- Electrical interference: If the thermocouple wires are exposed to electrical interference, such as from nearby power lines or equipment, this can cause interference in the thermocouple’s output signal, leading to inaccurate temperature readings.

Overall, proper installation, use, and maintenance of the thermocouple can help to minimize these failure factors and extend the lifespan and accuracy of the device.

How to Read a Thermocouple?

To read a thermocouple, you will need a thermocouple meter or a device that is capable of measuring the small voltage produced by the thermocouple. Here are the steps to read a thermocouple:

- Turn on the thermocouple meter or device and allow it to warm up for a few minutes before taking measurements.

- Connect the thermocouple to the meter or device according to the manufacturer’s instructions. The positive and negative wires must be connected correctly, or the readings may be inaccurate.

- Insert the thermocouple probe into the material or environment that you want to measure the temperature of. Make sure that the probe is in good contact with the surface of the material or environment.

- Wait for a few seconds to allow the thermocouple to stabilize and take a reading from the meter or device. The reading will display the temperature in the units of your choice, such as Celsius or Fahrenheit.

- Record the reading and repeat the process as necessary to obtain multiple readings or to monitor changes in temperature over time.

It is important to note that thermocouples may require calibration periodically to ensure accurate readings. Calibration should be performed by a qualified technician or calibration laboratory. Additionally, it is important to follow safety precautions when using thermocouples, especially in high-temperature environments, to avoid injury or damage to equipment.

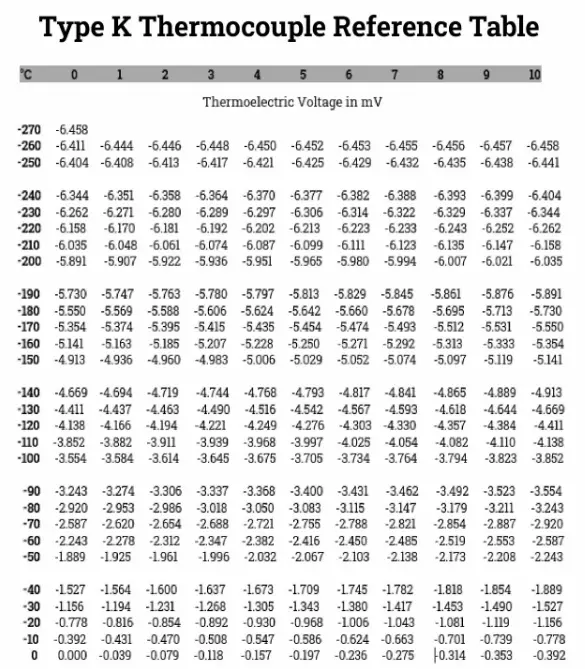

What is the meaning of the Thermocouple Reference Table?

A thermocouple reference table is a chart or table that provides a list of the temperature-to-voltage conversion values for a specific type of thermocouple at different temperatures. The reference table is based on the thermoelectric properties of the two metals used in the thermocouple, which produce a voltage that is proportional to the temperature difference between the hot junction and the cold junction.

The reference table is essential for accurately measuring temperatures using a thermocouple because it allows the user to convert the voltage output of the thermocouple into a temperature reading. The table typically includes the voltage output for the thermocouple at various temperatures, along with the corresponding temperature values in Celsius or Fahrenheit.

Different types of thermocouples have different reference tables, as the voltage output of each type of thermocouple varies based on the specific metals used in its construction. It is important to use the correct reference table for the specific type of thermocouple being used to ensure accurate temperature measurements. Fig. 2 provides a typical thermocouple reference table for type-k thermocouples.

Thermocouple for Water Heater

Type J thermocouples are commonly used for water heaters. This is because Type J thermocouples have a relatively low-temperature range and can measure temperatures up to around 750°C (1382°F), which is sufficient for most water heater applications. They also have good accuracy and stability at low temperatures, which is important for measuring the temperature of the water.

In addition, Type J thermocouples are inexpensive, widely available, and easy to replace if necessary, making them a popular choice for water heater manufacturers and maintenance professionals.

It is important to note that other types of thermocouples, such as Type K or Type T, may also be used for water heater applications depending on the specific requirements of the application. It is always recommended to consult the manufacturer’s documentation or industry standards to ensure proper selection and use of the thermocouple for a specific application.

Reference and Further Study

- https://www.iqsdirectory.com/articles/thermocouple.html