What if Underground Piping Continuation is Unknown?

It is necessary to specify the correct boundary conditions while modeling main pipeline stations: valve station, pig launcher, pump and compressor station etc. Sometimes engineers use anchor or hinged anchor (rest+guide+limit stop in other software) at the points of connection to the main pipeline. This trick work for above ground piping, but doesn’t work for buried main pipelines. The wrong model of pig launcher station is shown below.

Download this piping model file. See how to open the piping model file

For a very long buried pipeline the anchor is not enough to achieve enough safety margin. Even if temperature difference between installation and operation temperature is very small 10-40 degrees, then temperature expansion can be up to 100 mm due to huge length. Such a big displacements can damage the piping inside the station.

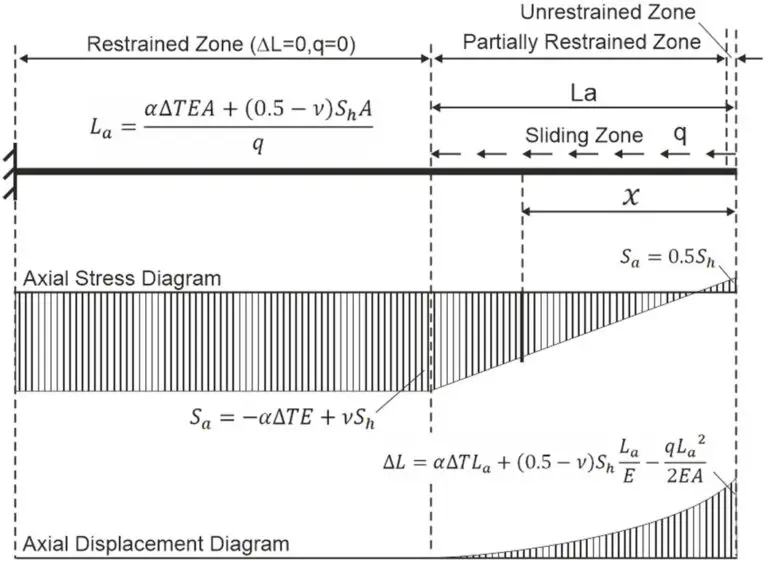

To correctly model the temperature expansion model must include the part of main pipeline with a length greater than La. Where La is a sliding zone length, also called virtual anchor length. In sliding zone pipe moves along it’s axis. But in restrained zone pipe doesn’t move. The maximum displacement umax will be a constant for any length of pipeline greater than La. For more information about this, please refer this arcticle.

To correctly model the temperature expansion of main pipeline, just add the pipe with length greater than La value (see picture below).

La value can be found by three ways:

- Using Manual Calculations

- Using Start-Elements Procedure

- Using step-by-step pipeline length increasing

Using Manual Calculations

The equation for “La” is given on the picture above

Using Start-Elements Procedure

Start-Elements is a special part of PASS/START-PROF software that allows to calculate wall thickness of pipes, bends, tees, reducers, spacing between the supports, stability analysis and much more.

Calculation of virtual anchor length (sliding zone length) in Start-Elements looks like this:

Using Step-by-Step Pipeline Length Increasing

To select the pipe length just add the pipe with some initial length. For example 100 m. Then run analysis and check stresses or support loads. Then increase the pipe length, for example to 150 m and run analysis again. If stresses or support loads become greater, then you need to increase the pipe length again and repeat analysis. Continue increasing of the pipe length until the stresses or support loads become almost the same as at previous analysis. It means that the pipe length already greater than La. START-PROF analysis is a very fast and allows to run analysis several times per short period of time, so this method is easiest.

Then the correct model is ready, maybe you will need to add U-, Z- or L-shape pipe loops to compensate the temperature expansion of connected main pipeline that is shown by dotted arrow on the picture below.

Please see the related video at 24:20, like, share and follow our channel: