Fluid Flow is generally measured inferentially by measuring velocity through a known area. With this indirect method, the flow measurement is the volume flow rate ”Q” stated in its simplest terms.

Volume flow rate (Q)

It is expressed as a volume delivered per unit time and typical units are gallons/min, m3/hr, and ft3/hr.

Q = A * V

Where: A is the cross-sectional area of the pipe & V is the fluid velocity.

Mass or weight flow rate

Expressed as mass or weight flowing per unit time. Typical units are kg/hr, Ib/hr.

This is related to the volume flow rate by F = p * Q

where

- F = Mass or Weight flow rate.

- p = mass density or weight density.

- Q = volume flow rate

Factors affecting Flow in Pipes

- Velocity (V) of the fluid.

- The friction of the fluid in contact with the pipe.

- Viscosity (µ) of the fluid.

- The density of the fluid.

The most important flow factors can be correlated together into a dimensionless parameter called the Reynolds number. It describes the flow for all velocities, viscosities, and pipeline sizes.

In general, it defines the ratio of velocity forces driving the fluid to the viscous forces restraining the fluid, or:

RD = VDρ/µ

D=Diameter ;

Fluid Flow in Pipes

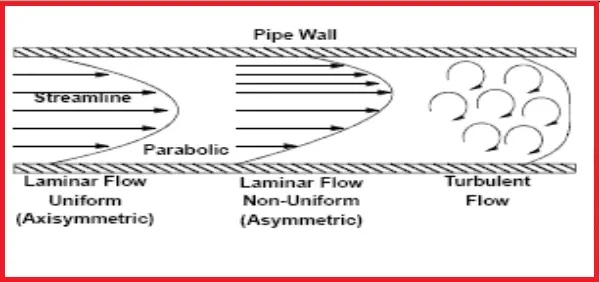

At very low velocities or high viscosities, RD (Reynolds Number) is low and the fluid flows in smooth layers with the highest velocity at the center of the pipe and low velocities at the pipe wall where the viscous forces restrain it. This type of flow is called laminar flow and is represented by Reynolds numbers below 2,000. One significant characteristic of laminar flow is the parabolic shape of its velocity profile

At higher velocities or low viscosities, the flow breaks up into turbulent eddies where the majority of flow through the pipe has the same average velocity. In the “turbulent” flow the fluid viscosity is less significant and the velocity profile takes on a much more uniform shape.

Turbulent flow is represented by Reynolds numbers above 4,000. Between Reynolds number values of 2,000 and 4,000, the flow is said to be in transition.

Measurement of Fluid Flow inside a Pipe

The type of device used often depends on the nature of the fluid and the process conditions under which it is measured.

Flow is usually measured indirectly by first measuring a differential pressure or a fluid velocity. This measurement is then related to the volume rate electronically.

Flow meters can be grouped into the following generic types:

- Head Type Flow Meters– Orifice Plates, Venturi, Flow Nozzles, Pitot Tubes, etc.

- Target Flow Meters.

- Positive Displacement Type Flow Meters such as Nutating Disc, Rotating Valve, Oval Gear, Oscillating Piston, Roots (Rotating Lobes), Rotating Impeller, etc.

- Velocity Type Flow Meters such as Turbine Meters, Electromagnetic Flow Meters, Vortex Flow Meters, Ultrasonic Flow Meters, etc.

- Mass Flow Meters such as Thermal Mass Flow Meters, Coriolis Mass Flow Meters, etc

All the above flow meter types will be explained in my future articles.

Flow Fundamentals

Accurate Measurement Requires the Right Meter Choice for the Application

Newtonian fluid

A Newtonian fluid is defined as a fluid that, when acted upon by applied shearing stress, has a velocity gradient that is solely proportional to the applied stress. Petroleum products and most mixtures of particles in petroleum products are Newtonian fluids.

The accuracy of flow meters is based on the steady flow of a homogenous, single-phase Newtonian fluid, and for turbine and ultrasonic meters a defined velocity profile does not alter the coefficient in long, straight runs of pipe.

Raynolds Number

A dimensionless parameter expressing the ratio between the inertia (driving) and viscous (retarding) forces.

It is given by the formulas:

Re = 2214 x BPH / (D x n)

Or

Re = 351 x M3/hr / (D x n)

where: The flow rate is in BPH barrels/hour (or M3/hr); D is the diameter of the meter in inches and n is the kinematic viscosity of the fluid.

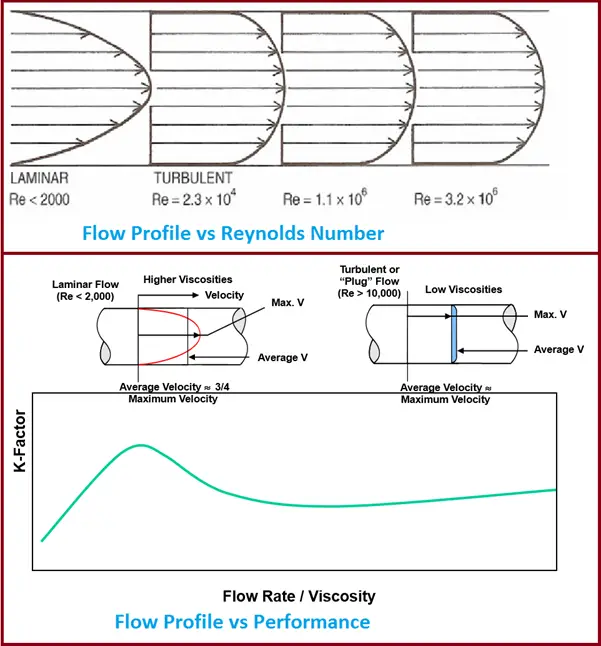

Fig. 2 below shows the curves for flow profile vs Reynolds number and Flow profile vs Performance

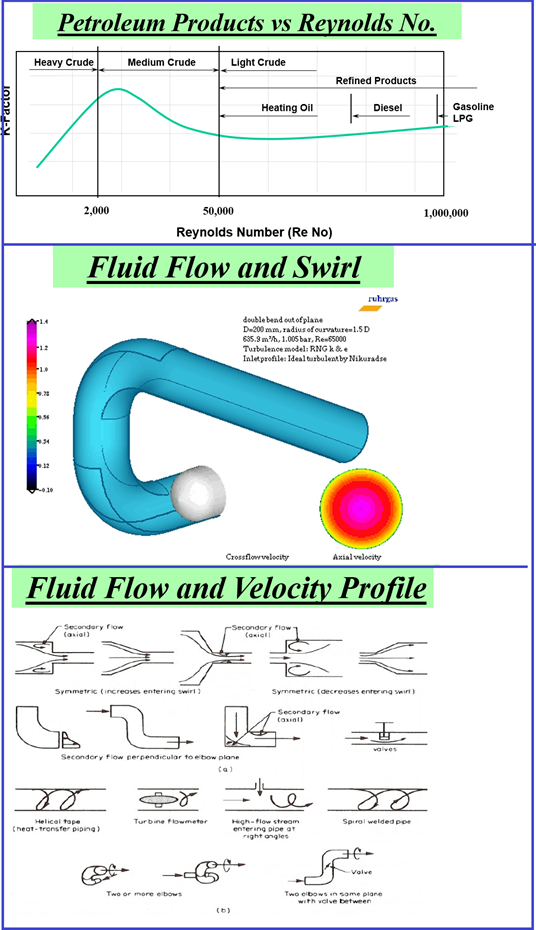

Figure 3 shows various curves/profiles related to Fluid Flow.

how can i get steady uniform velocity through out the cross section of the pipe without changing the flow parameters much.

Great and helpful content. Any content on Sludge Flow?