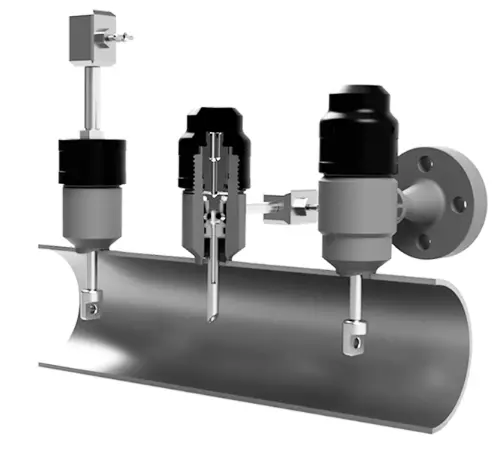

Access fittings are used in operating piping and pipeline systems. To insert or remove corrosion probes, bio-probes, erosion probes, chemical injection fittings, sacrificial and impressed current anodes, electrical resistance probes, corrosion coupons, hydrogen probes, thermowell, linear polarization probes, etc. a special type of fittings known as access fitting is used. In this article, we will learn about various types of access fittings used in pipe and pipeline systems.

What are Access Fittings?

Access fittings are special pipe fittings that can be installed under full process conditions providing internal access to production plant vessels and pipework. So, the use of access fittings avoids any kind of costly system shutdowns for obtaining various vital information like corrosion data. They are high-pressure fittings and are available for a rating of up to 10,000 psi.

Applications of Access Fittings

Access fittings find applications in various industries. Some of the sectors where access fittings are used are:

- Oil & Gas

- Chemical and Petrochemical

- Heavy Manufacturing

- Cooling Systems

- Process Sampling Systems

- Sand monitoring Systems

- Pipeline Systems, etc.

Chemical injection equipment uses access fittings to inject a wide range of chemicals like Corrosion Inhibitors, Dewaxers, Biocides, Neutralizing Agents, Boiler Water, Oxidants, Demulsifiers, Oxygen Scavengers, Flocculants, etc.

Access Fittings Styles

Access fittings are available in various styles as listed below:

- Welded

- Buttweld

- Socketweld

- Flareweld

- Flanged

- API Flange

- ANSI Flange

- Threaded (NPT)

Special access fittings using Graylok or Techlok connectors are also available commercially.

Components of Access Fitting

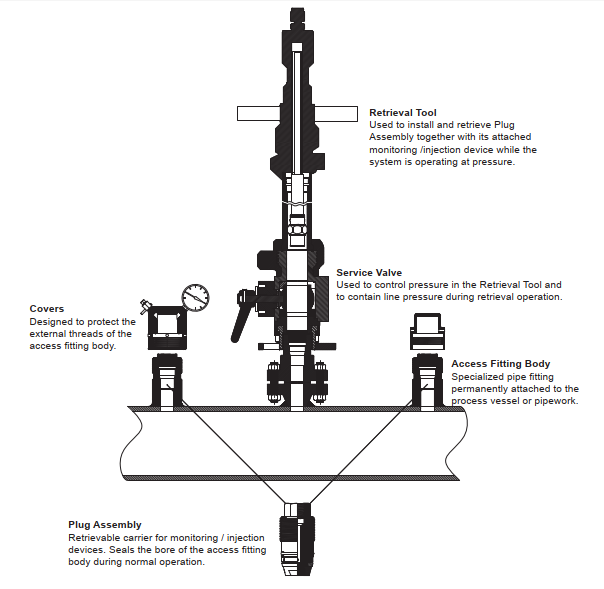

The assembly of access fitting has three main parts. They are:

- Protective cover to protect the external threads of the access fitting body.

- Plug-It is the carrier of the installed device. May be solid or hollow depending on the application. The plug assembly screws into the body of the access fitting and seals the fitting bore to contain line pressure.

- Access Fitting Body-the specialized pipe fitting which is permanently attached to the process plant vessel or pipework.

To perform the online installation and retrieval of the plug assembly, components like retrieval tools and service valves are required. The service valve contains the line pressure when the plug assembly is removed. Maintaining a number of access fitting assemblies are possible using one service valve and one retrieval tool.

Solid vs Hollow Plug Assembly for Access Fittings

Access fittings can be installed with a solid or hollow plug assembly. For example, Access fittings for corrosion coupon and chemical injection fittings use a solid plug assembly, whereas hydrogen probes, bio-probes, and corrosion probes use hollow plug assemblies. The main difference between them is that the hollow plug assembly allows the probe to directly pass through the plug.

Access Fittings for Chemical Injection

For chemical injection, the access fittings are installed on top of piping at locations of high turbulence. They usually have a tee connection with an isolation valve where the chemical injection line is tied in. The tee is generally an NPT thread, flanged connection, or a Nipolet. To avoid the risk of accidental damage, the tee pipe of the chemical injection fitting is aligned with the pipe axis. The injection fitting is supported by the main pipe where it is installed.

Corrosion Coupons

Corrosion coupons are an effective way to detect and track corrosion over time. this is one of the simplest corrosion monitoring techniques. In this method, the corrosion coupon is exposed to a process environment for a predecided duration and then remove for analysis. The basic analysis is weight measurement i.e, the weight loss of the corrosion coupon due to corrosion. Corrosion coupons are also known as Weight loss coupons. They are generally available in the following types:

- Strip type coupons

- Multi-disc coupons

- Ladder strip coupons

- Flush disk coupons