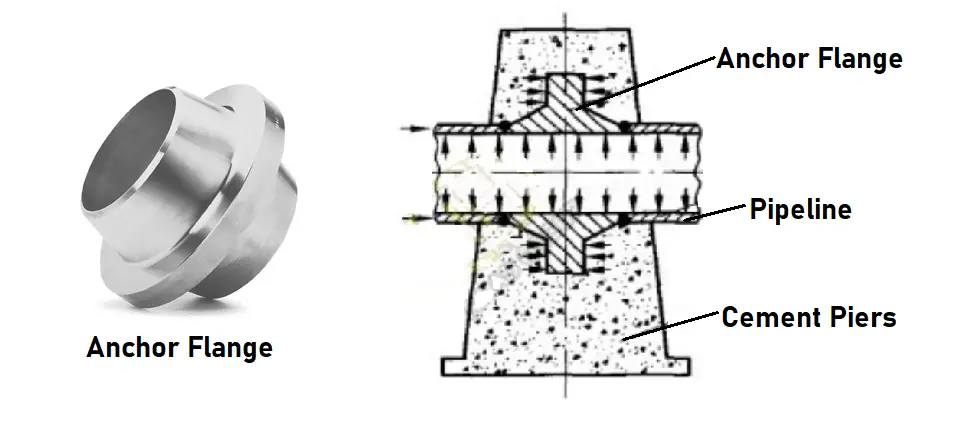

An Anchor flange is a forged fitting that looks like a weld neck flange with shape. It resembles a pipe flange but acts as an anchor in pipelines. This is the reason they are popularly known as Anchor Flange. Anchor flanges are embedded inside reinforced concrete blocks and are specifically used in pipelines to limit the thermal expansion/contraction forces and thrust forces. The weight of an anchor flange is usually estimated according to two weld neck flanges of the same size.

Uses of Anchor Flanges

Anchor flanges in pipelines are installed in various ways. Some of the typical locations for installing anchor flanges are:

- points of directional change

- suction and discharge laterals of the pumping station at a river crossing

- connections to equipment at meter run

- to secure subsea piping and risers to the platform structure

Anchor flanges immobilize the pipe at predetermined locations decided by pipeline stress engineers and transfer built-up stresses to external structures. The use of anchor flanges protects equipment and valves from very high stresses that could be generated due to the temperature and pressure of the line.

Features of an Anchor Flange

The concrete that embeds the anchor flange must be designed considering the loads for the worst operating scenario. Normal practice is to calculate the anchor flange loads using pipe stress analysis software.

Anchor flanges are supplied with end weld bevels that match the pipeline wall thickness. Widely used materials for anchor flanges are SA 105 and high-yield stress such as SA 694, F52, F60, F65, and F70. In general, the sizes of anchor flanges range up to 42”, however, larger custom sizes can be available. Each anchor flange is designed following the rules mentioned in ASME VIII Div.1 with the data taken from the process datasheet supplied by the customer.

For large-diameter, high-pressure, and long-distance oil and gas pipelines, anchor flanges act as important supporting members. They are normally placed underground or buried.

An anchor flange is a type of flanged axisymmetric ring body. Both sides of the flange are symmetrical flange necks. The ends of the two flanged necks are each welded to the end of the pipe and embedded in the anchor pile. The two flanges are connected by bolts, combined with existing technology, the gasket is removed, and the flange is connected to the gas transmission pipeline by welding to create an integral flange, which is fixed by the flange body and the anchor pile. Can be used for pipeline connection repair.

Anchor Flange Dimensions

Dimensions of anchor flanges are obtained from ASME B16.5. The anchor flange dimensions vary with respect to the pressure class and size of the pipeline. In general, all dimensions including thickness increases when the pressure class increases for the same size of the pipeline. Again, the anchor flange dimensions increase with respect to the increase in pipeline sizes for the same pressure class.

Ordering Information for Anchor Flanges

The following information must be provided while ordering an anchor flange.

- Nominal pipeline size and wall thickness

- Pipeline material details

- Design code

- Design temperature and pressure

- Corrosion allowance

- Installation temperature

- Allowable concrete bearing stress

- Maximum axial load

- Other applicable moments and load information

Hi Sir

Hi Sir,

How do you model anchor flange in CAESAR II and what all parameters are concerned..?