Piping Engineering is not a standalone activity. To successfully finish all engineering aspects piping engineer needs to depend on other disciplines in terms of input and output. While designing a piping system, many inputs are required from other disciplines and at the same time inputs are given to other disciplines too. There are also a few outputs generated by piping that is required for the procurement, erection, and fabrication of the piping system. This article will list a few such inputs and outputs to give the readers an idea in brief.

Inputs to Piping Discipline

- Requirements from the client: Plot area and location, statutory requirements, special requirements, software to be used, etc.

- Process licensor: Project design basis, design code, plot plan, PFDs (Process Flow Diagram), P&IDs (Piping and Instrumentation Diagram), PDS (Process Data Sheet), process description, equipment list, line list, site data, licensor, capacity, etc.

- Process information: Process data sheet showing overall dimensions, supporting arrangement, all nozzles location, size, rating, etc. for equipment.

- Civil/Structural layout, drawing: Effluent & drain sewer layouts and manhole location.

Civil drawings (plan and elevation) for the facilities within the unit like the instrumentation control room, electrical substation, and laboratory.

Pipe racks and technological structure foundation drawings.

Civil drawings for platforms.

Tank settlement data. Soil Properties. - Instrument drawing:

Tray width requirement on pipe rack/sleepers.

Instrumentation hook-up drawing.

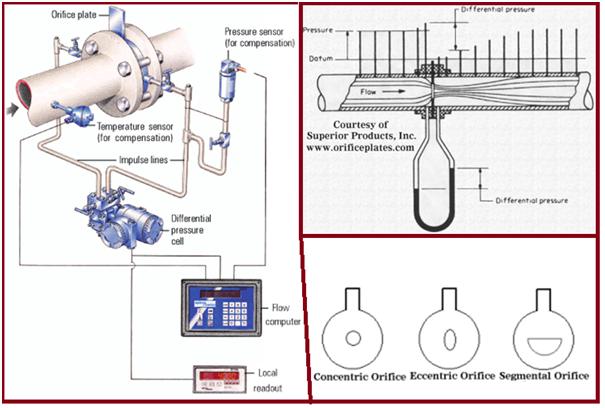

Instruments drawings for control valves, safety valves, inline instruments, etc. - Electrical layout:

Tray width requirement on pipe rack/pipe sleepers and cable trenches width in units/off-site.

Electrical cable tray layout. - Mechanical (Static/Rotary/Package) layout:

Mechanical datasheets for equipment like columns, vessels, tanks, etc. Layout drawing of package items showing auxiliary equipment. - HVAC (Heating, Ventilation, and Air conditioning): Layouts showing the HVAC duct size and the location.

Outputs from Piping Discipline:

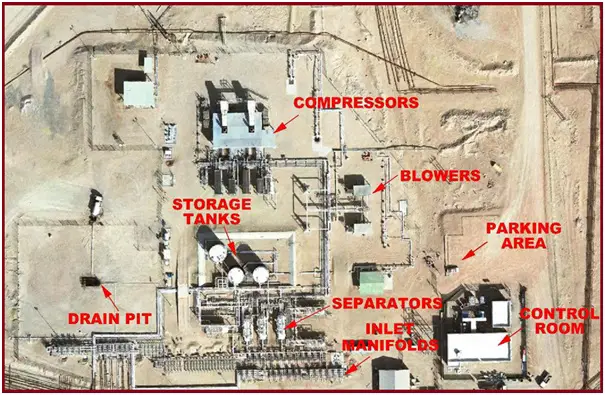

- Overall plot plan showing the location of various units, tank farms, offsite, package units, non-plant buildings, roads, culverts, pipe racks, sleepers, etc.

- PMS (Piping Material Specification)& VMS (Valve Material Specification).

- Equipment general arrangement drawing/layouts indicating the location of all the equipment within the unit, platforms, ladders, overhead crane elevation, monorail location, and cutouts for piping.

- Pipe rack general arrangement drawing & structures for equipment support

- Piping general arrangement drawing/Layouts showing all the piping and equipment.

- Piping Bill of Materials (BOM) with technical evaluation and technical bid analysis (TBA).

- Piping stress analysis report for the critical lines.

- Support loading for critical lines for structure design.

- A drawing showing the vessel cleat locations for pipe supports and platform/ladder.

- Layout for underground services.

- Piping isometrics with the bill of material.

- Support location plan, support schedule, and pipe support drawings.

- Purchase specifications for insulation, painting, wrapping, and coating.

- Material handling study.

It’s a very good initiative and helping people to develop a career in piping

What documents required while making piping equipment layout. for eg. distance between two equipments.

What are piping output to interdisciplinary

Hi Sir,

Iam working as a piping checker. I need piping checker rules and responsibilities. Please explain to me.

Thanks