ASTM A106 is an international (American) specification of carbon steel pipe. ASTM A106 is a widely used standard specification for seamless carbon steel pipes used for high-temperature service. The specification covers pipes from NPS 1/8 (DN6)to NPS 48 (DN 1200). All pipes under ASTM A106 are suitable for bending, welding, and other forming operation. A106 is also known as SA106.

Grades of ASTM A106 Materials

Depending on the chemical composition (mainly Maximum Carbon percentage) of A106 material, there are three grades of ASTM A106 materials. They are:

- A106 Grade A, having a maximum of 0.25% carbon.

- A106 Grade B, having a maximum of 0.30% carbon, and

- A106 Grade C, having a maximum of 0.35% carbon.

In the chemical composition of the different grades as mentioned above, the percentage range of manganese also varies slightly with respect to grade. A106 Grade A usually has 0.27 to 0.93% manganese while A106 Grade B and C generally have 0.29 to 1.06% Manganese. The maximum percentage of other elements like phosphorus, sulfur, silicon, copper, chromium, molybdenum, nickel, vanadium, etc are usually the same in all three grades of ASTM A106 carbon steel material. However, ASTM A106 provides a note of caution for these other elements saying the total combined percentage of all these other materials shall not exceed 1%.

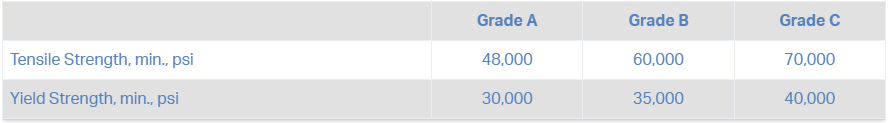

As the maximum carbon percentage of different grades of A106 material varies in chemical composition, so vary their mechanical strengths. While A106-A has a minimum yield strength of 30 KSI (205 MPa) and A106-B has a minimum yield strength of 35 KSI (240 MPa), the other grade A106-C has the largest minimum yield strength of 40 KSI (275 MPa). In a similar way, the tensile strength also varies. Both tensile and yield strength increase when we move on from Grade A to Grade C but at the same time, the percentage elongation reduces.

Difference Between A106 Grade A, B, and C

The main difference between ASTM A106 Grade A, B, and C are their maximum carbon percentage in the chemical composition and corresponding change in mechanical properties like tensile and yield strength, elongation, etc as discussed above.

Properties of A106

In general, A106 pipes have the following properties:

Density: 7800 – 8000 kg/m3

Elastic Modulus: 190 GPa (27557 KSI) – 210GPa (30458 KSI)

Poisson’s Ratio: 0.27 – 0.30.

Difference between ASTM A106 and ASTM A53

Both A106 and A53 are carbon steel pipes having wide applications. However, there are some differences between ASTM A106 and ASTM A53 pipe materials. The major differences that differentiate A106 pipe material from A53 pipes are provided in the following table:ASTM A106 ASTM A53 ASTM A106 pipes are seamless pipes. On the other hand, ASTM A53 pipes can be seamless or welded. As per chemical analysis, A106 has silicon in its chemical composition. ASTM A53 pipes do not have silicon in their composition. A106 pipes are generally costlier than A53 pipes. A53 pipes are usually cheaper than A106 pipes. A106 pipes are usually used for high-temperature pressure applications. A53 pipes are usually not applied for high-temperature applications.

Difference between A106 and SA106

As a piping engineer, you must have heard that some are referring to the pipe as A106 while some are referring to SA106. So, a question always arises in our mind, “what is the difference between A106 and SA106 pipe materials”?

In general, there is no difference between pipe material A106 and SA106. The only difference is in their material standards. ASTM standard uses the callout A whereas the ASME standard uses the SA callout for pipe materials. The 2013 edition of the ASME II material chapter has confirmed that SA106 is consistent with ASTM A106. So basically, SA106 is a grade of American ASME while A106 is the grade of ASTM.

Is ASTM A106 killed carbon steel?

Yes, all three grades of ASTM A106 carbon steel seamless pipe materials are killed carbon steel.

Difference between A106-Gr. B and A333-Gr. 6

The main difference between A106 Gr B and A333 Gr 6 is that A333-6 is an LTCS material whereas A106-B is CS material. The lower temperature at which A106 Gr B pipe material can be subjected without impact testing and stress ratio checking is -28.90C (For thickness up to 12.7 mm as per table 323.2.2A of ASME B31.3 ) Whereas A333 Gr 6 material is already proven for use up to a temperature of -460C (Refer Table A-1M). Moreover, A106-B pipes are seamless whereas A333-6 pipes can be seamless or welded.

Hi Anup sir,

I’m following your blog more than a year. What is killed carbon steel?

Hi Anup,

Presume A106-B is subjected to impact testing, is A106-B able to go even lower temperature than A333-6 which is -46 degC ? In terms of economics, which one is more expensive simply say both used at -40degC ?

Hi. I am looking for information about the strain resistance. I am involved in a project in which the contractor is looking to put NPT threads on this pipe and hang it to 700m to use as tremie pipe in a deep borehole. I am concerned the threads will not hold. Would appreciate any leads on the specifications or how to calculate that.

thanks