To cater to heavy-duty industries such as oil and gas, petrochemical, and power generation, engineering materials must possess exceptional strength, durability, and resilience to withstand harsh environments and extreme conditions. One such material that has stood the test of time and has earned a reputation for its outstanding mechanical properties is ASTM A516. In this article, we delve into the world of ASTM A516 material, exploring its composition, properties, and diverse applications, and understanding why it is considered a vital pillar of strength in various industrial sectors.

What is ASTM A516?

ASTM A516 is a specification that defines the requirements for carbon steel plates used in moderate and lower temperature service. The material is widely known for its excellent weldability and notch toughness, making it ideal for pressure vessels, boilers, and storage tanks where reliable performance is crucial. ASTM A516 is commonly used in industrial settings to ensure the safe containment of gases and liquids under varying temperatures. Note that SA 516 is the ASME designation of the same material A516.

Grades of ASTM A516

Steel plates under ASTM A516 specification are graded based on their minimum tensile strength. There are four grades of A516 material.

- ASTM A516 Gr 55 having a minimum tensile strength of 55 ksi

- ASTM A516 Gr 60 having a minimum tensile strength of 60 ksi

- ASTM A516 Gr 65 having a minimum tensile strength of 65 ksi, and

- ASTM A516 Gr 70 having a minimum tensile strength of 70 ksi

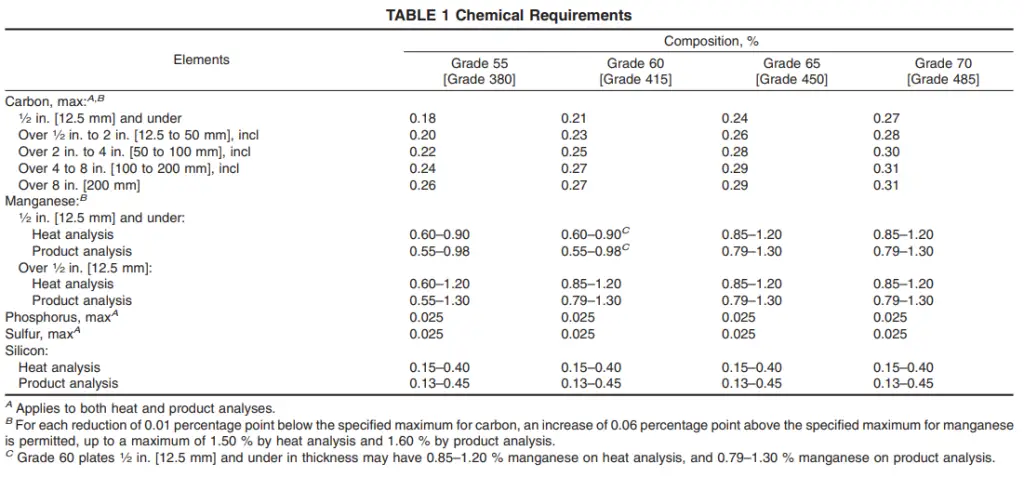

Chemical Composition of ASTM A516 Material

The key characteristic of ASTM A516 is its composition, which primarily includes carbon, manganese, phosphorus, sulfur, silicon, and elements like copper, nickel, chromium, and molybdenum in trace amounts to enhance specific properties.

- Carbon Content: The carbon content in ASTM A516 steel ranges from 0.18% to 0.31%, ensuring that the material remains strong and resilient without being too brittle. The carbon content in A516 material increases when the grade increases from A516 grade 55 to A516 grade 70.

- Manganese: With manganese content of 0.6-1.30%, ASTM A516 gains improved formability and strength, crucial for resisting deformation under high-stress conditions.

- Phosphorus and Sulfur: These elements are maintained at low levels, typically less than 0.025%, to enhance the material’s ductility and prevent brittleness.

- Silicon: In ASTM A516, silicon is limited to 0.15% to 0.45%, imparting better oxidation resistance and aiding in deoxidation during the steelmaking process.

- Trace Elements: The presence of trace elements like copper, nickel, chromium, and molybdenum contributes to increased corrosion resistance and better mechanical properties at low temperatures.

Refer to Fig. 1 below that provides the chemical compositions of ASTM A516 material based on grades.

Mechanical Properties of ASTM A516 Material

Mechanical properties of ASTM A516 are given in the following table:

| Parameter | A516 Grade 55 [Grade 380] | A516 Grade 60 [Grade 415] | A516 Grade 65 [Grade 450] | A516 Grade 70 [Grade 485] |

|---|---|---|---|---|

| Tensile strength, ksi [MPa] | 55–75 [380–515] | 60–80 [415–550] | 65–85 [450–585] | 70–90 [485–620] |

| Yield strength, min, ksi [MPa] | 30 [205] | 32 [220] | 35 [240] | 38 [260] |

| Elongation in 8 in. [200 mm], min, % | 23 | 21 | 19 | 17 |

| Elongation in 2 in. [50 mm], min, % | 27 | 25 | 23 | 21 |

Applications of A516 Material

ASTM A516 material finds widespread application in various heavy industries due to its exceptional mechanical properties and adaptability to different environmental conditions. Some of its key applications include:

- Pressure Vessels: ASTM A516 steel is primarily used in the construction of pressure vessels, which store and transport pressurized gases and liquids. These vessels are common in chemical processing plants and power generation facilities.

- Boilers: Boilers in power plants require materials capable of withstanding high-pressure steam at elevated temperatures, making ASTM A516 a natural choice for their construction.

- Storage Tanks: The material’s superior toughness and resistance to corrosion make it an ideal choice for storage tanks that house a wide range of substances, such as crude oil, chemicals, and liquefied gases.

- Piping Systems: ASTM A516 is used in the fabrication of pipes and tubing, ensuring the reliable conveyance of fluids and gases within industrial processing plants.

ASTM A516-Gr 60 vs ASTM A516-Gr 70

ASTM A516 Gr 60 and ASTM A516 Gr 70 are two different grades of carbon steel plates specified by the American Society for Testing and Materials (ASTM). These grades are designed to be used in moderate and lower temperature service, primarily in pressure vessel, boiler, and storage tank applications. Both grades are widely utilized in various heavy industries due to their excellent mechanical properties and weldability.

ASTM A516 Gr 60:

Tensile Strength: The tensile strength range for ASTM A516 Gr 60 is between 60 to 80 ksi (415 to 550 MPa). This means that the material has a minimum yield strength of 60 ksi and a maximum tensile strength of 80 ksi.

Yield Strength: ASTM A516 Gr 60 has a minimum yield strength of 32 ksi (220 MPa), which indicates the point at which the material will permanently deform under tension.

Elongation: The minimum elongation in 8 inches (200 mm) for ASTM A516 Gr 60 is 21%, and for 2 inches (50 mm), it is 25%. Elongation represents the ability of the material to stretch before breaking.

ASTM A516 Gr 70:

Tensile Strength: The tensile strength range for ASTM A516 Gr 70 is between 70 to 90 ksi (485 to 620 MPa). This indicates that the material has a minimum yield strength of 70 ksi and a maximum tensile strength of 90 ksi.

Yield Strength: ASTM A516 Gr 70 has a minimum yield strength of 38 ksi (260 MPa), showing its ability to withstand a certain amount of stress before permanent deformation.

Elongation: The minimum elongation in 8 inches (200 mm) for ASTM A516 Gr 70 is 17%, and for 2 inches (50 mm), it is 21%.

Comparing ASTM A516 Gr 60 and ASTM A516 Gr 70, it is evident that Gr 70 has higher tensile strength and yield strength than Gr 60. This difference makes Gr 70 more suitable for applications that require higher mechanical properties, especially in situations where higher pressure and stress levels are anticipated. On the other hand, Gr 60 is a cost-effective option for applications with less demanding mechanical requirements.

In summary, ASTM A516 Gr 60 and ASTM A516 Gr 70 are both valuable materials with specific mechanical properties, allowing engineers and fabricators to select the most suitable grade for their particular industrial applications based on the required strength and service conditions.

Conclusion

ASTM A516 material has become an indispensable part of heavy industries where strength, resilience, and safety are of paramount importance. Its widespread usage in pressure vessels, boilers, storage tanks, and piping systems demonstrates its ability to endure the most challenging environments. As technology continues to advance, ASTM A516 steel remains a pillar of strength, assuring the smooth and safe operation of critical industrial processes. Its legacy of reliability and durability continues to make it a preferred choice in various applications, setting a benchmark for other engineering materials to follow.

I hope you can help me. I recently was given a box with some round steel objects. They are labeled and all say Grade 55 ALONG with ASTM number 516-72. I am trying to find out that they are used for. I did some research and found mention of milling process of steel. I have a picture I can send. I would very much appreciate any help you can render.