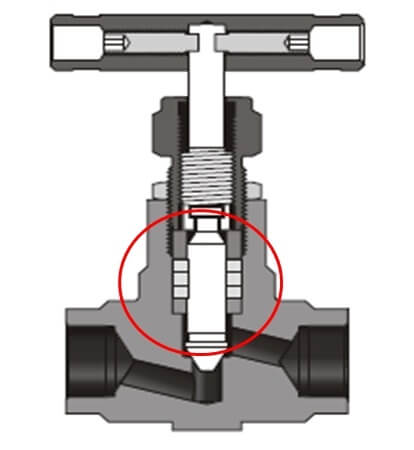

In a piping system, There are a lot of ways to isolate the flow. Many types of valves and blinding systems are available for this. But the use and purpose of the Needle valves are very different. Needle valves are sometimes referred to as Plunger valves. This helps piping professionals to perfectly control and regulate fluid flow and pressure. The Needle valve got its name because of its narrow needle-like plug and port arrangement. The needle valves are small in size but fluid flow controlling is of exceptional accuracy.

Needle valves are linear motion valves, Which are used in instrument systems for throttling small volumes. A needle valve is a manual valve that is used where continuous throttling is required for flow regulation. Needle valves are somehow similar to globe valves in design with the biggest difference of sharp needle-like disks of this. The needle valve has an isolation system with very precise which is attended by the fine movement of the shaft, which enables the gearbox to move the piston tube in a sliding motion for opening and closing position. In this article, we will help you to understand the following:

- What is a Needle valve?

- Symbols and uses of Needle valves

- Parts of Needle valves

- Working Principle of Needle valve

- Advantages and Disadvantages of Needle valves

What is a Needle Valve?

A needle valve is a type of valve that can be used to regulate or complete the isolation of the fluid. The unique feature of the valve is the structure of a small plunger with the shape of a Needle. The plunger features a small handle to operate the easy and precise operation of the valve. When fully attached, the extended end of the valve fits exactly into the seat, a part of the appliance that is being regulated. In case of the valve is opened by mistake, then also space between and needle and the seat is so less, that a minimal amount of substance will be allowed to pass through it.

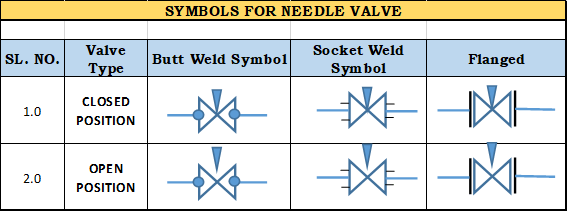

Needle Valve Symbol

Like Every pipe fitting and Special Item, the Needle valve has its own symbology system. Common Needle Valve Symbol is shown in Fig. 2.

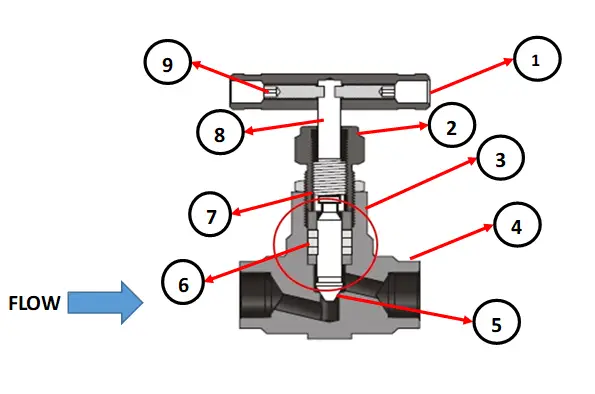

Parts of a Needle Valve

Needle valves consist of three major parts, the valve body and seat, the stem and stem tip, and the packing and bonnet. The stem incorporates fine threads to allow micrometer-like needle adjustment relative to the seat.

Referring to the above image and corresponding marked serial numbers name of parts of the needle valve is as below:

- Valve handle

- Nut

- Bonnet

- Valve body

- Seat

- O-ring

- Packing

- Stem

- Handle screw

The needle valve body is normally made up of Brass, Bronze, Stainless Steel, or any other alloy materials. Valve seats are usually manufactured from PVC, CPVC, Plastic, PTFE, or Thermoplastic Materials.

Depending on the position of the needle, needle valves are available in three basic configurations.

- as a simple screw-down valve (T-type needle valve)

- oblique needle valve (angle pattern) that offers a more direct flow path, and

- controlled outlet flow at a right angle to the main flow.

Needle valves normally provide Z- or L-shaped flow path through the body.

Application of Needle Valves

Wherever precise flow measurement is the required role of the needle valve comes into play. In comparison with a diaphragm valve, a Needle valve can handle more differential pressure.

Needle valves find their application in almost every industry wherever control or metering of steam, gas, oil, air, water, or other non-viscous liquids is needed. Needle valves are widely used in Power generation, Zoological sciences, Cooling, Instrumentation control, and Gas and liquid dispensation industries.

In slurries and viscous media, the needle valve is avoided as a small orifice can easily be blocked by thick material or solids.

Role of Needle Valves

The major roles that a needle valve performs are

- Flow control

- In pump start

- Pressure regulation

- Turbine by-pass

- Flow discharge

- Air regulation

- Reservoir inlet

Use of a Needle Valve

A needle valve finds its wide uses in the following applications:

- All analog field instruments are installed with a needle valve to control the flow movement.

- Needle valves help in situations where the flow needs to stop gradually.

- The needle valve can be used as an on/off and throttle valve.

- This can be used where metering applications are required such as steam, air, gas, oil, or water.

- A needle valve is helpful with sample points in piping where a very little flow rate is required.

- This valve can be used on gas bleeder lines.

- Needle valves are used in automated combustion control systems in which accurate flow regulation is required.

- It is used with constant pressure pump governors in order to reduce the fluctuation in the pump discharge

Types of Needle Valve

Depending on the operation style, three types of needle valves are available in the market. They are:

- Manually operated threaded needle valve

- Motorized Needle Valve: Use an electric or pneumatic actuator for operation.

- Angle Needle Valve: Turn the output by 90 degrees instead of in-line.

Working Principle of Needle Valves

Needle valves can be operated either manually or automatically. Manually operated needle valves use a handwheel to open or close their disc. When Handle is turned in a clockwise direction its plunger lifts to open the valve and allow fluid to pass through. When the Handle is turned in an Anti-clockwise direction the plunger moves closer to the seat to decrease the flow rate and finally intercepts the flow of fluid.

Automated needle valves are connected to the hydraulic motor or an air actuator that helps to automatically open and close the valve. The motor or actuator will help to adjust the position of the plunger according to the timer or external data fed into the system, that is gathered during monitoring.

Both manually and automatically operated needle valves provide precise control of fluid flow rate. The handwheel is accurately threaded which means it takes multiple turns to adjust the position of the plunger from the seat. As a result, the needle valve can help better in regulation the flow rate in the system.

Needle Valve Design Standards

Frequently used needle valve design standards governing the valve design and selection are:

- ASME B16.34

- BS 7174 P4

- MIL-V-24586

- PIP PNDMV09N

Needle Valve Selection

The parameters that affect the selection of the right needle valve are

- Valve Material: Depends on the application

- Temperature and Pressure rating

- Size of the Valve, Port, and Orifice Size

Advantages of Needle valve

The main advantages that a needle valve serves are

- With the help of this valve flow control at a very low rate with higher accuracy is possible.

- Needle valves are smaller in size. So, there is no issue of space during its installation.

- Throttling even with less volume of fluid is possible with this valve.

- Flow rates can be adjusted precisely.

- Its operation is easier.

Disadvantages of Needle valve

A few drawbacks of needle valves are

- There is a high-pressure loss in the needle valve because of the high restriction of fluid flow.

- They can be used only for low-flow rate piping systems.

- There can be damage to the seat and needle if the fluid has solid particles.

- It is not possible to say if it is in an open or closed position just by examining the handle position.

- Immediate opening or closing is not possible in these types of valves. Immediate operations can damage the seat of the need valve.

Ball Valve vs Needle Valve

The main differences between a ball valve and a needle valve are tabulated below:

| Ball Valve | Needle valve |

| Ball valves use a Spherical ball for valve operation | Uses a needle to open and close the valve |

| Ball valves are Quarter turn Valve | Needle valves are Linear motion valve |

| Ball valves have Poor flow control | Needle valves have precision flow control |

About the Author

A major part of this article is written by Mr. Vaibhav Raj, a Piping Engineer by profession, currently working with a leading MNC as an Asst. Manager (Piping). To date, He successfully executed four Oil and Gas Projects in India with various clients Like EIL, RIL, SHELL, and RSPL. He is the lead author of the blog “ALL About PIPING“.

Interesting

Hi Anup,

I have few questions regarding the design of needle valves.

How does the shape of needle (sharp/blunt) affect the force/friction required to fully open/close the valve.

What are the different components that affect the turning torque of the handle. Is there some simple way to estimate it.