Safety and Reliability is the most important factor in construction and engineering. Bolting is a widely used component in piping engineering. So, the choice of bolting materials can make or break a structure. These small mechanical fasteners play a critical role in holding together everything from towering skyscrapers to intricate machinery. And in piping engineering, bolts find wide applications in bolted joints. They are the unsung heroes of structural integrity, ensuring that the pieces of a puzzle fit snugly together and withstand the test of time. In this blog post, we will explore the world of bolting materials, finding their types, characteristics, and importance in various industries.

Types of Bolting Materials

Bolting materials come in a variety of types, each tailored to specific applications and environments. The choice of material depends on factors such as load-bearing capacity, corrosion resistance, temperature variations, and more. Some common types of bolting materials include:

- Carbon Steel: This is the most common and cost-effective bolting material. It offers good strength and durability, making it suitable for general-purpose applications. However, carbon steel is prone to corrosion, especially in humid or corrosive environments.

- Stainless Steel: Stainless steel bolts are renowned for their exceptional corrosion resistance. They are often used in environments with high moisture content or exposure to corrosive substances. The addition of chromium gives stainless steel its anti-corrosive properties.

- Alloy Steel: Alloy steel bolts are engineered to offer specific mechanical properties, such as high strength or resistance to extreme temperatures. They are commonly used in industries like aerospace and automotive, where precise engineering is crucial.

- Titanium: Titanium bolts are favored when both strength and lightweight properties are essential. They find applications in industries like aerospace and medical equipment manufacturing.

- Brass and Bronze: These materials are known for their corrosion resistance, making them suitable for decorative applications or where a specific aesthetic is desired. They are often used in furniture and architectural elements.

- Nickel Alloys: Bolts made from nickel alloys exhibit exceptional resistance to heat, corrosion, and stress. They are commonly used in chemical processing and oil and gas industries.

All the bolting materials types are presented in Fig. 1 below:

The following table provides the common bolt materials along with the compatible nut materials and applicable temperature range:

| Body Materials | Temperature | Temperature | Bolting Material Specifications | |

| (degrees F) | (degrees C) | |||

| Bolts | Nuts | |||

| Cast Iron | -20 to 410 | -29 to 210 | ASTM A307 Gr B | ASTM A307 Gr 7 |

| Ductile Iron | -20 to 650 | -29 to 343 | ASTM A193 Gr B7 | ASTM A194 Gr 2H |

| Carbon Steel (Grade WCB) | -20 to 800 | -29 to 427 | ASTM A193 Gr B7 | ASTM A194 Gr 2H |

| Carbon Steel (Grade LCB) | -50 to 650 | -29 to 343 | ASTM A193 Gr B7 | ASTM A194 Gr 2H |

| Carbon Moly (Grade WC1) | -20 to 800 | -29 to 427 | ASTM A193 Gr B7 | ASTM A194 Gr 2H |

| 801 to 850 | 427 to 455 | ASTM A193 Gr B7 | ASTM A194 Gr 7 | |

| 1¼Cr-½Mo (Grade WC6) | -20 to 800 | -29 to 427 | ASTM A193 Gr B7 | ASTM A194 Gr 2H |

| 801 to 1000 | 427 to 538 | ASTM A193 Gr B7 | ASTM A194 Gr 7 | |

| 2¼Cr-1Mo (Grade WC9) | -20 to 800 | -29 to 427 | ASTM A193 Gr B7 | ASTM A194 Gr 2H |

| 801 to 1000 | 427 to 538 | ASTM A193 Gr B7 | ASTM A194 Gr 7 | |

| 1001 to 1050 | 538 to 566 | ASTM A193 Gr B16 | ASTM A194 Gr 7 | |

| 5Cr-½Mo (Grade C5) | -20 to 800 | -29 to 427 | ASTM A193 Gr B7 | ASTM A194 Gr 2H |

| 801 to 1000 | 427 to 538 | ASTM A193 Gr B7 | ASTM A194 Gr 7 | |

| 1001 to 1100 | 538 to 566 | ASTM A193 Gr B16 | ASTM A194 Gr 4 | |

| 9Cr-1Mo (Grade C12) | -20 to 800 | -29 to 427 | ASTM A193 Gr B7 | ASTM A194 Gr 2H |

| 801 to 1000 | 427 to 538 | ASTM A193 Gr B7 | ASTM A194 Gr 7 | |

| 1001 to 1100 | 538 to 566 | ASTM A193 Gr B16 | ASTM A194 Gr 4 | |

| Type 304 (Grade CF8) | -425 to 100 | -254 to 38 | ASTM A320 Gr B8 | ASTM A194 Gr 8 |

| 100 to 1500 | 38 to 815 | ASTM A193 Gr B8 | ASTM A194 Gr 8 | |

| Type 347 (Grade CF8C) | -425 to 100 | -254 to 38 | ASTM A320 Gr B8 | ASTM A194 Gr 8 |

| 100 to 1500 | 38 to 815 | ASTM A193 Gr B8 | ASTM A194 Gr 8 | |

| Type 316 (Grade CF8M) | -325 to 100 | -198 to 38 | ASTM A320 Gr B8 | ASTM A194 Gr 8 |

| 100 to 1500 | 38 to 815 | ASTM A193 Gr B8M | ASTM A194 Gr 8M | |

| 3½Ni (Grade LC3) | -150 to –50 | -101 to -46 | ASTM A320 Gr L7 | ASTM A194 Gr 4 |

| -50 to 650 | -46 to 343 | ASTM A193 Gr B7 | With Charpy Test or 8M ASTM A194 Gr 2H | |

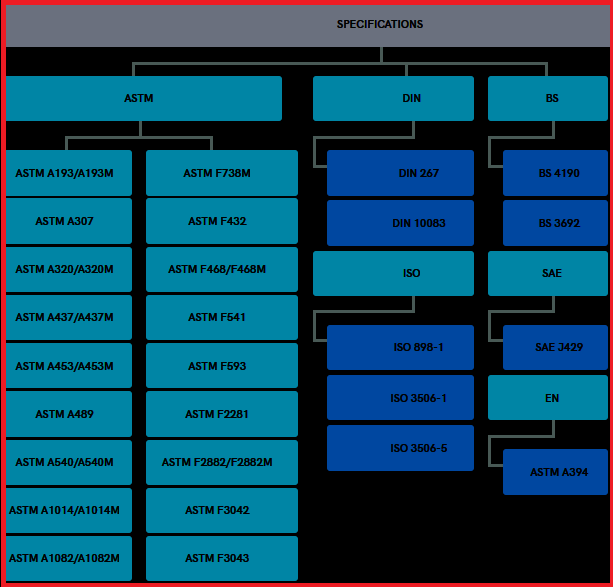

Fig. 2 below shows the detailed specification of bolting materials:

Characteristics and Considerations

When selecting bolting materials, several key characteristics and considerations come into play:

- Strength: The primary purpose of a bolt is to hold components together securely. The strength of the material determines its load-bearing capacity and resistance to deformation.

- Corrosion Resistance: Depending on the environment, bolts may be exposed to moisture, chemicals, or other corrosive agents. Choosing a material with appropriate corrosion resistance is crucial for longevity.

- Temperature Resistance: Some applications involve extreme temperature variations. Bolts should be able to maintain their integrity and strength in such conditions.

- Ease of Installation: Bolts should be easy to install and tighten. Some materials require specific torque specifications for proper installation.

- Cost: The choice of bolting material can significantly impact project costs. While high-performance materials might be ideal, budget constraints often come into play.

- Compatibility: Bolting materials should be compatible with the materials being joined. Galvanic corrosion can occur when dissimilar metals come into contact.

Importance in Various Industries

Bolting materials play a critical role in a wide range of industries:

- Construction: In buildings and infrastructure, bolts ensure that beams, columns, and other structural elements remain securely connected.

- Automotive: Bolts are used throughout vehicles, from engine components to chassis elements, contributing to safety and performance.

- Aerospace: The aerospace industry demands lightweight yet strong materials. Titanium and other alloys are crucial for aircraft components.

- Oil and Gas: In harsh environments, such as offshore drilling rigs, bolts made from nickel alloys are used to withstand corrosive conditions.

- Manufacturing: Machinery assembly relies on bolts to keep moving parts together and ensure operational efficiency.

Bolting Features

Essential bolting features for piping engineering are mentioned here.

Conclusion

Bolting materials might seem like minor components in the grand scheme of construction and engineering, but their significance cannot be overstated. The right choice of material can mean the difference between a structure that stands the test of time and one that falters under pressure. As technology and materials science continues to advance, the world of bolting materials evolves, offering new possibilities for enhanced safety, durability, and performance in various industries. So, the next time you marvel at a towering skyscraper or a precision-engineered machine, remember that the strength of those structures often hinges on the humble bolt.