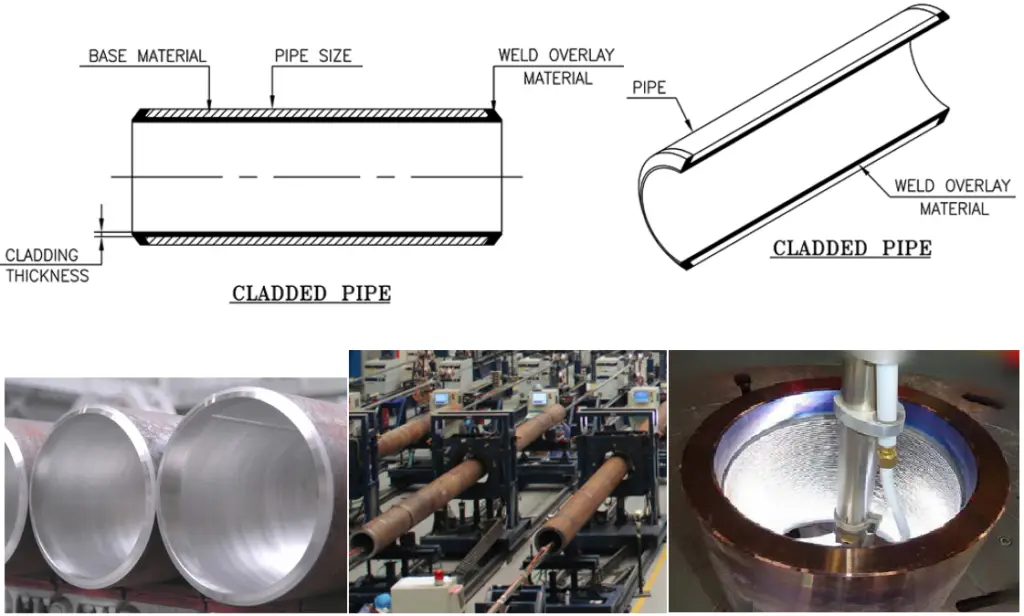

A Cladded Pipe is a steel pipe having a metallurgically bonded Corrosion-Resistant Alloy (CRA) layer on its internal or external surface. The base material is carbon steel or low alloy steel. Clad pipes comply with the most stringent requirements of strength and corrosion resistance. The carbon steel outer pipe (backing steel or base metal) complies with the static requirements of strength and durability, whereas the highly alloyed inside pipe provides protection against corrosion. As more and more pipelines are operated under highly corrosive conditions, the use of CRA-cladded pipe is increasing in the pipeline industry, especially in offshore areas.

Applications of Cladded Pipe

An internal layer of corrosion-resistant alloy (CRA) material, known as a cladding material, is economically suitable as the thinner layer enhances the corrosion-resistant abilities with increasing cost. Because of this, cladded pipe is extensively used in subsea pipelines and natural gas industries for conveying sour oil and gas, saltwater pipelines, water reinjection systems, process pipes in the chemical industry, saltwater pipes, water injection pipelines, inter-field pipelines, riser pipelines, flow lines, power plants, and marine applications.

CRA Materials for Cladded Pipe

An extensive range of stainless steel and non-ferrous alloy materials to suit the temperature requirements can be used as cladded pipe material. In normal industrial applications the following materials are found suitable as cladding materials:

- Stainless Steel SS 304, SS 316, SS 317, SS410,

- Duplex Stainless Steel,

- Alloy Steel 254 SMO 904,

- Incoloy alloy 825, Inconel alloy 59, Inconel alloy 625,

- Hastelloy C-276,

- Hastelloy C-22,

- Hastelloy B3,

- UNS N0 8825, UNS N06625, UNS N04400,

- Alloy 31,

- AL6NX,

- Alloy 20,

- Monel alloy 400,

- Zirconium,

- Titanium, and

- some copper alloys

The cladding material shall conform to ASTM A265, B898, B424, B443, B619, A240, A263, A264, B622, B675, B265, B551, etc. The thickness of the CRA layer is normally 0.25 mm to 6 mm.

Cladding material types and thicknesses can be selected to meet the specified environment.

API 5LD provides basic requirements for CRA cladded line steel pipe.

The main parameters that are considered while selecting a CRA material are:

- Temperature

- Chloride Concentration

- Partial Pressure of CO2 and H2S

- Environment pH

- Presence or absence of Sulphur

Manufacturing of CRA Cladded Steel Pipes

Two common types of pipe cladding processes are available for bonding the CRA cladding pipe layer to the steel pipe:

1. Metallurgical bonding of cladding pipe:

The metallurgical bonding of the cladding can be achieved by various methods like Weld Overlay, explosion bonding, hot rolling, coextrusion, powder metallurgy, etc. Clad plates are utilized as raw materials. However, The main problem with metallurgical bonding is the high costs due to a limited number of suppliers for such a complex and demanding manufacturing process of metallurgical bonding the plates.

Weld Overlay Process

Weld Overlay is the most widely used metallurgical bonding process for pipe cladding. A Weld Overlay is also known as cladding, weld cladding, hard facing, or weld overlay cladding. In this process, one or more metals are joined together via welding to the surface of a base metal (backing steel) as a layer. Surfaces prepared by the weld overlay method can even be highly customized by layering and alloying multiple different materials together.

The weld overlay process is suitable for smaller as well as very large diameter pipe spools, flanges, and fitting. The main benefits that weld overlay pipe cladding provides are:

- The weld overlay process can be applied to complex requirements.

- It provides long life and high-reliability corrosion resistance to harsh environment applications.

- Weld overlay is an economical way to provide excellent corrosion resistance for steel without jeopardizing design thickness.

Other Metallurgical Bonding Processes

For manufacturing cladded pipe by explosion bonding, two dissimilar materials are bonded with the help of pressure and heat produced by the explosion. The clad material is kept on top of the base material and then the explosive material is spread on it. Upon ignition of the explosive, the resultant thrust bonds the clad plate on the base plate underneath. Depending on the job requirements, various combinations of the clad plate and base plate thickness can be bonded.

Roll bonded cladding technique is usually used for the mid-range of pipe sizes (16″ to 24″). Some of the advantages of Roll-bonded metallurgical bonding cladding methods are:

- It provides a better surface as compared with overlay welding.

- Roll-bonded clad plates are an economical alternative to expensive high-alloy solid plates. An optimum combination is arrived at by the mechanical properties of the base material and the corrosion resistance of the cladding material.

- As compared with solid plates, it has thinner wall thicknesses and better workability.

- More homogeneous bonding and a wider range of dimensions compared with explosion cladding.

2. Mechanical bonding of Cladding Pipe:

Mechanical bonding of the CRA pipe and the base steel pipe is performed by using spring back variation using Hydroforming or full-length pipe expander. Hydroforming is more expensive than a full-length pipe expander.

Inspection of CRA Cladded Pipes is done using Ultrasonic Testing Methods.

Difference between Clad and Lined Pipe

Some of the differences between a cladding pipe and a lined pipe are listed below:

| Cladded Pipe | Lined Pipe |

| Metallic material is used for cladding. | For lining, non-metallic material is used. |

| Weld Overlay or explosion bonding process. | Mechanical bonding process with adhesive |

| Suitable for high temperature and pressure applications. | Normally used in low-pressure and temperature applications |

| Complicated fabrication | Easy fabrication because of flanged joints. |

| Economically Costly | Comparatively cheaper. |

What about laying methods ?

Good knowledge shared here. thank fellow

Would you mind sending me a reference book for Piping Stress analysis?

Thanks for sharing your experience and knowledge in short state and quick understanding.

Can anyone recommend a company in Europe for inner cladding with Inconel. No pipes but casings, which means geometry is more tricky than a straight pipe.

Thanks Anup for sharing your valuable knowledge, very well explained..

In one of the projects, our client proposed to us SS 316 cladding instead of solid SS316 to save cost. Never come across SS316 cladding, as all the clients uses In 625 Cladding.Can you share in any of the projects ,where you have used SS cladding in topside piping(offshore) for oil and gas industry?

Please share Pros and cons of SS cladding if any.

What do you think about the CO-X SEAMLESS COEXTRUDED CLAD PIPE?

Many thanks