The energy consumption of the world is increasing day by day. As per the energy requirements for the future, the energy production required will be in big capacity. The high-capacity energy production like Three Gorges, Jebel Ali, and Kashiwazaki-Kariwa will be producing more than 10,000 MW. However, as fossil fuel is non-renewable and is being consumed at a higher rate than produced, it will end up in the next 46 years. At the same time, fossil fuels create a huge level of pollution in the environment. To control pollution and meet the future energy demand the only option is renewable clean energy.

Clean energy is a form of energy that originates from zero-emission renewable sources. When consumed, clean energy does not pollute the atmosphere. Clean energy produces power and energy without producing negative impacts on the environment.

As per the RE100 initiative, where hundreds of big companies have already announced their commitment to get 100% of their power from renewable sources, the energy that emits little to no greenhouse gas emissions and includes renewable and carbon-free sources is more adaptable along with the high requirements. Piping systems of these energy sources are sometimes challenging due to the geographic and energy characteristics, including resources like

- Geothermal Power

- Biomass Power

- Hydropower

- Nuclear Energy

- Hydrogen Energy

- Solar Power

Geothermal Energy

Indonesia is estimated to have about 28 GW of geothermal potential for power generation, located on the Ring of Fire, and is home to more than 200 volcanoes which account for 40 percent of the geothermal potential of the entire world. 41 volcanoes are present over the island, making it a highly active seismic zone, providing abundant geothermal resources. Thus holds the highest potential for energy production. Wayang Windu is the world’s largest flash steam power plant.

Wayang Windu has 227 MW of total installed capacity, due to the high power generation and the geographical features of the land over there often experiences high thermal expansion & contraction, shifts in the ground, changes in elevation, uneven terrain, and also the need to disassemble and relocate the piping system, making construction or expansion of plants, wells and the piping systems that connect them often presenting several challenges and resulted in a complex piping scenario. In permanent welding, the rigid joints would not be able to provide the flexibility to accommodate thermal and seismic movement. To alleviate these problems, grooved mechanical piping was specified, installation of the flexible couplings was less time-consuming than welding and flanged joint, and they provided a small amount of angular and linear movement, meeting the requirements for flexibility and maintainability and offering additional benefits onsite.

Biomass Plants

Ironbridge power plant which is located at the Severn Gorge, UK, is the world’s biggest biomass power plant. As fuels materials like wood chips and palm kernel shells, which offer a more stable alternative. Wood chips will get transported inside the pipelines as water slurries employing this loss on lower heating value would preclude the usage of water slurry pipelines for direct combustions, this biomass delivered through pipelines is suitable for processes that do not produce contained water as vapor (eg. supercritical water gasification).

Renewable natural gases (RNG) and renewable hydrocarbon fuels formed from existing waste streams and renewable and sustainable biomass sources like animal waste, crop residuals, and food waste by various processes such as hydrotreating, pyrolysis, gasification, and other thermochemical and biochemical technologies,

The same chips transported in a heavy gas oil take up as much as 50% oil by weight and result in a fuel that is >30% oil on a mass basis and is about two-thirds oil on a thermal basis.

Production of bends with flow-optimized radii can minimize the pressure loss & reducing the number of welds can increase benefits, RNG makes an important energy tool.

Hydropower

The traditional renewable energy resource is famous due to the geographic features of India and is in use in over 160 countries. In hydroelectric power plant (HPP)projects usually, it will be steeply inclined with rough terrain conditions. To adjust to these conditions grp pipes are used more as they are lighter, thus it will be easier for the transportation and installation of these materials. Operations carried out at high-altitude areas may bring about lower temperatures.

Conventional hydropower generation is highly cost-effective and not feasible in certain areas. Times changed, and steps have developed for making use of hydropower more effectively. Lucid Energy came out with an idea to make it possible by fixing a small turbine in the existing water pipeline doing the trick. They are designed along gravity-fed, pressurized transmission and distribution lines, effluent outfalls, and other pipe conveyance systems. These micro-hydro systems can be positioned in municipal water, wastewater, industrial water, and irrigation systems.

They can operate across a wide range of head and flow conditions inside most common piping materials such as steel, ductile iron, concrete, or any material that can be mated with steel pipe thus they can provide clean and baseload energy, without interference of wind and solar and environmental repercussion. Since most of the piping runs underground.

Nuclear Energy

Other than Hydropower; nuclear energy is by far one of the highest sources of energy production. Even though nuclear energy is renewable, the fuel that is required is not renewable, Nuclear power plants over the world that can produce 1 GW of energy are considered to be the most reliable source of energy. The conditions under which the fission takes place are extremely hostile, and most of them are situated on the coast and use seawater for cooling which calls for special piping resistant to the high corrosiveness of saltwater. means the finest stainless-steel pipes and tubing are required so that they can deal with high temperatures and pressure along with corrosiveness nickel alloys are also been used in the nuclear industry widely as it a widely adaptable element and have a great range of properties such as heat and corrosive resistant.

Apart from that next-generation nuclear power is also a widely discussed topic Concepts so far include nuclear reactors dozens or even hundreds of times smaller and more distributed. also trying to develop offshore nuclear reactors, like the floating platforms the oil and gas industry already uses. They should be able to withstand Category 5 hurricanes.

In the case of power loss during an emergency, the supply of cold seawater would always be available to cool the reactor core as the reactor core submerged beneath the platform.

Hydrogen Energy

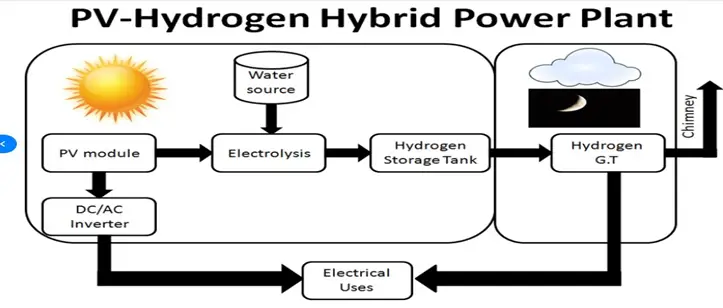

Over the past years, the utilization, research, and demonstration of hydrogen energy has risen and are already widely used in some industries, as for as now so many types of research are ongoing to reduce the barriers present now and also to reduce the costs considering its potential to support clean energy transitions, currently natural gas is considered to be the primary source of hydrogen production. They can also be extracted from fossil fuels and biomass, from water, or a mix of both.

On the other hand, Green hydrogen(H2) is obtained by steam reforming or else by splitting water by electrolysis. The physical and chemical properties of hydrogen are different from those of natural gas, so it is not possible to exchange natural gas for hydrogen in the existing natural gas pipe system. The durability of the existing pipelines is still one of the limiting factors.

As we know hydrogen is highly inflammable and dangerous to compress, and it can also alter traditional steel pipes and welds. Improperly designed pipes, valves, and fittings of these piping systems can cause small leaks and cracks which can lead to the failure of the pressurized gas.

For designing the hydrogen pipeline and piping systems, the ASME B31.12 piping code has been published. Typically carbon steel and sometimes alloys are used in production plants.

For delivering large volumes of hydrogen, existing pipelines are used as the economical option. some of the technical concerns of the pipeline transmission are,

- hydrogen has the potential to embrittle the steel and welds used to fabricate the pipelines

- controlling hydrogen permeation and leaks

- requirement for lower cost, hydrogen compression technology which is more reliable, and more durable.

Using FRP pipelines for hydrogen distribution is a potential solution, also the installation charges for these pipelines are more than 20% less than steel pipelines as they are obtained in sections that are much longer minimizing the welding requirements.