I had already published an article that relates to the most common ferrous materials used in the piping industry. Click here to visit the page. In this article, I will mention the most frequently used non-ferrous piping materials.

Pipes made of Plastic materials | Plastic Piping

In comparison with metallic materials, the use of plastics is limited to relatively moderate temperatures and pressures [230 deg C (450 deg F) is considered high for plastics]. Plastics are also less resistant to mechanical abuse and have high expansion rates, low strengths (thermoplastics), and only fair resistance to solvents. However, they are lightweight, are good thermal and electrical insulators, are easy to fabricate and install and have low friction factors. Since plastics do not corrode in the electrochemical sense, they offer another advantage over metals. The important thermoplastics used commercially are polyethylene, polyvinyl chloride (PVC), fluorocarbons (Teflon, Halar, Kel-F, Kynar), and polypropylene. Important thermosetting plastics are general-purpose polyester glass-reinforced, bisphenol-based polyester glass, epoxy glass, vinyl ester glass, furan, and phenolic glass, and asbestos reinforced. While using non-metallic piping, viz HDPE, PVC, FRP, etc, the designer shall take care of the service, pressure & temperature. The manufacturer’s recommendation shall be taken into account.

Thermoplastic Pipes

The most chemical-resistant plastic commercially available today is tetrafluoroethylene or TFE (Teflon). This thermoplastic is practically unaffected by all alkalies and acids except fluorine and chlorine gas at elevated temperatures and molten metals. It retains its properties up to 260 deg C (500 deg F). Perfluoroalkoxy, or PFA (Teflon), has the general properties and chemical resistance of FEP at a temperature approaching 300 deg C (600 deg F). Polyethylene is the lowest-cost plastic commercially available. Mechanical properties are generally poor, particularly above 50 deg C (120 deg F), and the pipe must be fully supported. Carbon-filled grades are resistant to sunlight and weathering. Polypropylene has a chemical resistance about the same as that of polyethylene, but it can be used at 120 deg C (250 deg F).

Thermosetting plastic Pipes

Among the thermosetting materials are phenolic plastics filled with asbestos, carbon or graphite, glass, and silica. Relatively low cost, good mechanical properties, and chemical resistance (except against strong alkalies) make phenolics popular for chemical equipment. Furan plastics filled with asbestos and glass have much better alkali resistance than phenolic resins. Polyester resins reinforced with fiberglass, have good strength and good chemical resistance except to alkalies. Epoxies reinforced with fiberglass have very high strengths and resistance to heat. The chemical resistance of the epoxy resin is excellent in non-oxidizing and weak acids but not good against strong acids. Alkaline resistance is excellent in weak solutions.

Pipes produced from Rubber and elastomers

Rubber and elastomers are widely used as lining materials. The ability to bond natural rubber to itself and to steel makes it ideal for lining tanks. Natural rubber is resistant to dilute mineral acids, alkalies, and salts, but oxidizing media, oils, and most organic solvents will attack it. Hard rubber is made by adding 25 percent or more sulfur to natural or synthetic rubber and, as such, is both hard and strong. Chloroprene or neoprene rubber is resistant to attack by ozone, sunlight, oils, gasoline, and aromatic or hydrogenated solvents, but is easily permeated by water, thus limiting its use as a tank lining. Nitrile rubber is known for its resistance to oils and solvents. Butyl rubber’s resistance to diluting mineral acids and alkalies is exceptional. Hypalon has outstanding resistance to ozone and oxidizing agents except fuming nitric and sulphuric acids. Fluoroelastomers (Viton-A, Kel-F, Kalrez) combine excellent chemical and temperature resistance.

Medium Alloys

A group of (mostly) proprietary alloys with somewhat better corrosion resistance than stainless steel are called medium alloys. A popular member of this group is 20alloy. Made by a number of companies under various trade names. Durimet 20, and Carpenter 20 are a few names. This alloy was originally developed to fill the need for a material with sulphuric resistance superior to stainless steel. Other members of this group are Incoloy 825 and Hastelloy G-3. These alloys have extensive applications in sulphuric acid systems. Because of their increased nickel and moly contents, they are more tolerant of chloride-ion contamination than standard stainless steel. The nickel content decreases the risk of stress-corrosion cracking and molybdenum improves resistance to crevice corrosion and pitting.

High alloys

The group of materials called high alloys all contain a relatively large percentage of Nickel. Hastelloy B2 contains 61% Nickel & 28% Mo. The alloy has unusually very high resistance to all concentrations of HCL at all temperatures in the absence of oxidizing agents. Other materials of this group are Chlorimet 2 & Hastelloy C-276.

Nickel & Nickel alloy Pipes

The metal is widely used for handling alkalies, particularly in handling and storing caustic soda. Neutral alkaline solutions, seawater, and mild atmospheric conditions do not affect nickel. A large number of nickel-based alloys are commercially available. One of the best known out of these is Monel 400 with 67% Ni and 30 % Copper. This Ni-Cu alloy is ductile and tough. Its corrosion resistance is better than its components, being more resistant than a nickel in reducing environments and more resistant than copper in oxidizing environments.

Pipes from Copper and copper alloys

Copper and its alloys are widely used in chemical processing, particularly when heat and thermal conductivity is very important. The main copper alloys are brasses(Cu-Zn), Bronzes( Cu- Sn), and Cupronickels. Some of the bronzes are very popular in the process industry, like Aluminium and silicon bronzes because they combine good strength with corrosion resistance. Cupronickels have 10-30% nickel and have become very popular because it has the highest corrosion resistance of all copper alloys. This finds its application in heat-exchanger tubing and its resistance to seawater especially outstanding.

Titanium Pipes

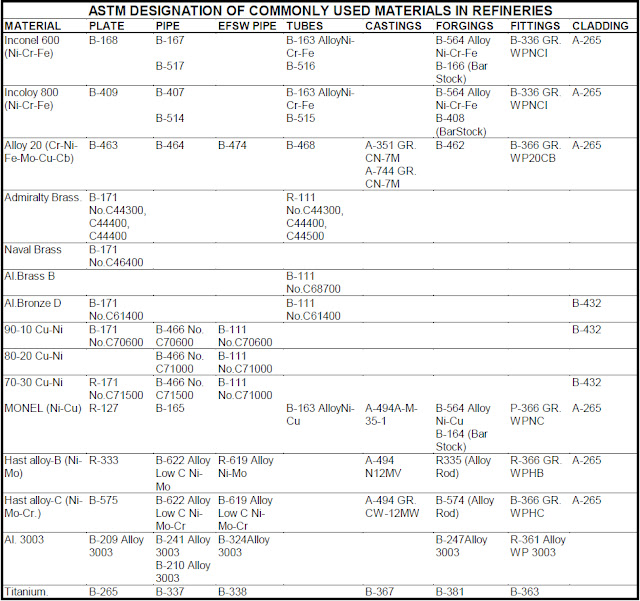

Titanium has become increasingly important as a construction material. It is strong and of medium weight. Corrosion resistance is very superior in oxidizing and mild reducing media. Titanium is usually not bothered by impingement attacks, crevice corrosion, and pitting attacks in seawater. Its general resistance to seawater is excellent. A detailed list of commonly used non-ferrous materials in hydrocarbon industries is given in the following table.

Great post! Nice information keep sharing, Thank you.

It’s really nice and meaningful. it’s really cool blog, Thank you.

Dear anup

please give a blog of lessons learnt in piping layout, stress & materials.which will be helpfull to all.