ANSI Pump and API Pump are two types of Centrifugal pump styles that are used in Chemical Plants, Refineries, and Oil and Gas Industries. They have some distinct differences. This article will compare the major features of both these pumps.

What is an API Pump?

An API Pump is a special type of centrifugal pump that meets the design, inspection, and testing criteria specified by the American Petroleum Institute’s API-610 standard for pumps. In Refineries and Petrochemical Industries, mostly API pumps are used as they provide very good operating experience in handling hydrocarbons (oil, gasoline, Natural gas, and petroleum products) due to their robust design. Generally, They come in many different forms employing a number of pumping mechanisms. Traditionally API pumps are considered very conservative (stringent) and costly.

What is an ANSI Pump?

ANSI Pumps are a type of horizontal, single-stage, end suction centrifugal pump that has an overhung impeller and back pull-out. This type of pump is designed based on the ASME B73.1 standard. Due to their low cost, they are popularly used in chemical industries, refineries, and industrial and mining applications for comparatively less temperature pressure applications. The main advantage of ANSI pumps is their interchangeability across manufacturers and brands.

ANSI Pump vs API Pump

Compared to an API pump, the typical ANSI pump has the following characteristics:

| Criteria | API Pump | ANSI Pump |

| Design Code | API 610 | ASME/ANSI B 73.1 |

| Pump Casing | Thick Casing, more corrosion allowance. In general, designed for 750 PSIG at 500℉. | Thinner Casing, less corrosion allowance. Normally designed for 300 PSIG at 300℉. |

| Nozzle Load | More sensitive to pipe-induced stresses, ANSI pumps allow reduced permissible nozzle load | More sensitive to pipe-induced stresses, hence ANSI pumps allow reduced permissible nozzle load |

| Stuffing Box Size | API pumps have a large Stuffing Box. | Smaller stuffing box size. Unless a large bore option is chosen, an ANSI pump may not be able to accommodate the optimum mechanical seal for a given service. |

| Impeller Design | API pumps feature closed impellers with replaceable wear rings. | ANSI pump impellers are designed and manufactured without wear rings. Many ANSI pump impellers are open or semi-open |

| Mounting Option | Normally, API pumps are center-line mounted | Generally, ANSI pumps are foot-mounted. |

| Application | API pumps are suitable for heavy-duty, much higher temperatures, and pressures | ANSI pumps are usually not suitable for moving thicker and/or viscous fluids. Moderate duty application. |

| Reliability | API pumps are highly reliable | The reliability of ANSI pumps is comparatively less. |

| Cost | High | Comparatively less |

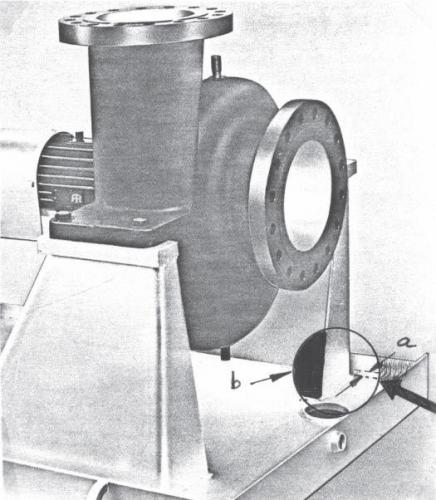

Refer to the attached sketch. In foot-mounted pumps, casing heat tends to be conducted into the mounting surfaces and thermal growth will be noticeable. It is generally easier to maintain the alignment of API pumps since their supports are surrounded by the typically moderate-temperature ambient environment.

Choosing Pump Type: API or ANSI

The decision on API vs. ANSI construction is experience-based and is not governed by governmental or regulatory agencies. However, experienced machinery specialists have their own likes and dislikes based on the experience gathered by them over their long years in the machinery field.

Many highly experienced and reliability-focused machinery engineers would prefer to use pumps designed and constructed according to API 610 for toxic, flammable, or explosion-proof services at on-site locations in close proximity to furnaces and boilers in some of the conditions (rules-of-thumb) that are listed below:

- Head exceeds 106.6 m (350 ft)

- The temperature of pumpage exceeds 149°C (300°F) on pumps with discharge flange sizes larger than 4 inches or 177°C (350°F) on pumps with a 4-inch discharge flange size or less.

- Driver horsepower exceeds 74 kW (100 hp)

- Suction pressure in excess of 516 kPag (75 psig)

- Rated flow exceeds flow at best efficiency point (BEP)

- Pump speed in excess of 3600 rpm.

The author mentions that there have been exceptions made where deviations from the rules-of-thumb were minor, or in situations where the pump manufacturer was able to demonstrate considerable experience with ANSI pumps under the same, or even more adverse conditions.

Finally, the author gives his opinion on choosing either API or ANSI pumps based on the following:

Conventional Wisdom: API-compliant pumps are always a better choice than ANSI or ISO pumps

Fact: Unless flammable, toxic or explosion-prone liquids are involved, many carefully selected, properly installed, operated and maintained ANSI or ISO pumps may represent an uncompromising and satisfactory choice.

The above comparison that is provided in the article is referenced from Heinz P. Bloch’s book “Pump User’s Handbook Life Extension” co-authored with Allan R. Budris.

Few more useful resources for you.

Pump Suction Intake Design with Sample Calculation

Pumps & Pumping Systems: A basic presentation

Stress Analysis of Water Pump Station Piping using Flexible Sleeve Coupling

Types of Pumps used in Process Plants

Cause and Effect of Pump Cavitation

Please send me pump documents.

I’m seeking for a job ,

Good

Simple and very usefull

It’s good to know that the decision between API and ANSI pups is experience-based. My uncle has been wondering which pump to choose for his project. I’ll recommend him to use an API pump.