We daily hear the word CNG! We know CNG is a type of fuel that powers our vehicles and is also an alternative to diesel and petrol. But we really don’t know anything beyond it. In this article, we dig a little deeper and try to understand what CNG is, why it is used, how it is obtained, and what its benefits are.

We try to look from a common man’s perspective and not from a technical angle. Keeping this in mind, I have tried to keep this article very simple and non-technical for common readers. Even a technical person will find this article very useful. So let us get started…

What is CNG?

CNG gas in full form is Compressed Natural Gas. It is a type of natural gas that is compressed under tremendous pressure. Some of the important physical characteristics of CNG are

- Odorless

- Colorless and

- Non Corrosive

Just like other fossil fuels like coal and oil, CNG is formed when decaying plants and animals which are buried under the earth’s surface interact with intense heat and pressure for millions of years.

Two main reasons why CNG is replacing traditional fossil fuels like petrol and diesel are

- CNG is a lot greener than diesel and petrol. Hence it emits very less carbon and other greenhouse gas. It reduces carbon monoxide emissions by 90% to 97%. It reduces environmental pollution significantly. So it is very eco-friendly.

- CNG is cheaper than petrol and diesel which makes it affordable for the common masses. It is also very efficient and easy to use.

It will come to you as a surprise that 98% of natural gas comes from North America.

Origins of CNG

In the mid-eighteenth century, experiments with CNG began. However, in the 1930s, automakers started experimenting with methane gas in their industry. In the 1960s, Columbia Natural Gas of Ohio tried a CNG carrier. The ship was supposed to transport compressed natural gas in vertical pressure columns but the pressure vessels were too expensive. Therefore it was abandoned.

After the 1990s many developing countries around the world like Iran, Brazil, Argentina, China, etc started using CNG for their vehicles. Most of the cars in these countries are powered by CNG. This led to an increase in CNG demand.

However, since 2008, the market for natural gas like CNG and LPG has really grown substantially. The main reason for this growth is increased petroleum prices and the desire to reduce carbon emissions.

You can imagine right now there are over 10 million natural gas-powered vehicles and more than 15,000 CNG refueling stations in 75 different countries.

Properties of CNG

We talked about some of the properties of CNG earlier. But here we shall see them in great detail.

- The state of the CNG is gaseous and it is an odorless, colorless, and tasteless gas. However, a chemical called methyl mercaptan is added to detect gas leaks.

- It is a highly combustible gas and a fossil fuel. It has a low flammability range and high ignition temperature.

- CNG is a mixture of simple hydrocarbon compounds especially Methane (CH4) with small amounts of ethane, butane, pentane, and propane.

- The gas has a high calorific value because it is free of any kind of toxicity.

- The byproducts of CNG after burning are water vapor and carbon dioxide.

- CNG and other natural gases are 60% lighter than air.

- Natural gas is found in rocks beneath the earth’s surface.

- Natural gas can be stored and transported through pipelines.

These were some of the main properties of CNG.

What CNG is Comprised of?

If we go beyond the physical appearance of CNG, we need to know what it is comprised of. I mean to say its chemical composition.

CNG is found in a gaseous state and consists of about 90% to 95% methane or CH4. The remaining 5% to 10% consists of nitrogen, carbon dioxide, helium, or hydrogen sulfide. Unlike LPG (Liquefied Petroleum Gas) which is a liquid comprised of propane and butane.

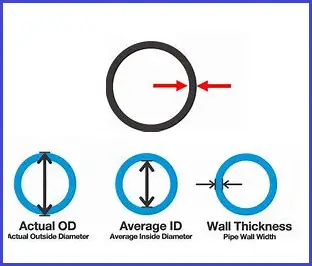

CNG is a natural gas that is compressed under great pressure so that it occupies a lesser volume in your fuel tank or fuel storage. CNG is compressed to a pressure of 200 to 500 kg/cm square or in other countries it can be 3600 pounds per square inch. In the compressed form, CNG occupies less than 1% of its volume at atmospheric pressure.

Although most of the vehicles can use natural gas in liquid as well as gaseous form but most vehicles use in gaseous form compressed to 3000 psi. CNG has an energy density of 53.6 MJ/Kg or 9 MJ/L.

Uses of CNG

CNG is used for both residential as well industrial purposes. Some of its uses are

- As you already know CNG is widely used by the transportation sector for powering cars, trains, ships, and other vehicles.

- The gas is used by end consumers for cooking and heating.

- Dryers use CNG for drying clothes. It is 50% more cost-effective than electricity.

- Some countries also use CNG for generating electricity.

- Manufacturing a huge range of chemicals like acetic acid, ammonia, methanol, butane, propane, ethane, etc. Even fertilizers are made using CNG.

- It is heavily used as chemical feedstock for manufacturing plastic and other commercially important organic chemicals.

- CNG is used in the production of glass, fabric, steel, paint, etc.

- Protein-rich animal and fish feed is produced by feeding CNG.

CNG has applications in both industrial as well as in the home but it is primarily used for transportation.

CNG Process

Generally, a typical CNG process includes 4 phases.

Phase 1: Production

A typical CNG production facility depends upon the quality of the natural gas and reservoir pressure. The production process consists of compression, cooling, dehydration, and most likely Liquefied Petroleum Gas (LPG) separation.

The extent of compression and cooling is going to differ from process to process.

Phase 2: Transportation

There are various CNG transportation processes that have emerged over the years. Some of them are

Coselle CNG Carrier – Creating a large but compact CNG storage with a pipe. It consists of several miles of small diameter pipe coiled into a carousel.

Volume Optimized Transport and Storage – It consists of long and large diameter pipes encased in an insulated shell.

Coiled Pipeline Carrier – It uses a coiled pipeline configuration.

Two other transportation processes are Gas Transport Modules and Pressurized Natural Gas Concept.

Phase 3: Receiving

In the receiving phase, the CNG ship unloads gas into the pipeline at the receiving terminal. The receiving terminal will have a dock with high-pressure pipeline connections and an expander to recover energy from the high-pressure gas.

Phase 4: Storage

Storage is required at the production and receiving terminal to maintain uninterrupted operation. The CNG can be stored in the ship docked at the port.

These were 4 simple phases or processes involved in CNG generation. I have tried to explain it in a non-technical manner so everyone can understand it easily.

Advantages & Disadvantages of CNG

To sum up this article I will give you both sides of the picture.

Advantages

- The most significant advantage of CNG is it is environment friendly and emits very low carbon. The numbers of pollutants released are far less than petrol and diesel. It means less greenhouse gas or CO2 emissions.

- Natural gas-powered vehicles have lower costs of maintenance compared to petrol and diesel-powered vehicles. This means consumers save a lot of money.

- In the event of a leak, the potential damage caused by CNG is far less than by other energy sources.

- CNG-powered vehicles produce less noise as compared to diesel vehicles.

- Women in remote villages in India live longer because of CNG. CNG is a clean fuel because it emits no smoke on the other hand wood and coal emit a lot of black smoke.

Disadvantages

- CNG demands more fuel storage space than petrol or diesel-powered vehicles.

- CNG from production to distribution emits a lot of greenhouse gas. So it is not that eco-friendly.

- The leak of methane gas can cause serious environmental damage.

- Most importantly, CNG has less energy density and power output than diesel or petrol vehicles.

I hope after reading this article you will get a clear idea of what CNG is, its properties, usage, and development process.

Hello Kumar.

I am Yahaya Okai a Nigerian and working on a possible CNG gas from flared gas point for power and NGV, It would be nice to see how we can collaborate in putting together in the process of the concept development for such, implementation and operational plan for such gas utilization process.

Let me see your thought process with regards to the above please.

Many thanks

You can reach me via my email or phone as below

yahayaokai@gmail.com

+2348033412407

The number is on whatsapp

So helpful ,well detailed and simplified.

I thought that the only use of CNG is in the transportation sector where we need to use compressed gas.

Are’nt all the other uses specified by you basically generic uses of natural gas (and not of compressed natural gas)? Why would anyone incur the additional cost of compressing gas where uncompressed gas can be used? Can you please clarify?