In the world of energy and industrial processes, there exists a versatile and widely used material that often goes unnoticed despite its significant role in powering economies and industries. Petroleum coke, often simply referred to as “petcoke,” is a carbon-rich byproduct of the oil refining process that has found its way into various sectors, playing a crucial role in energy generation, manufacturing, and more. This article dives deep into the layers of petroleum coke, exploring its production, characteristics, applications, and environmental considerations.

What is a Petroleum Coke?

Petroleum coke, commonly referred to as petcoke, emerges as a byproduct during the refining of crude oil. This carbon-rich solid substance serves a range of industrial and commercial purposes, including its utilization as a fuel source in power plants and cement kilns. The visual characteristics of petcoke can range from deep black to dark grey or even a warm golden brown hue, contingent upon its composition and the specific refining methods applied. The sulfur content of petoleum coke displays considerable variation, encompassing grades featuring both exceptionally low and remarkably high sulfur concentrations.

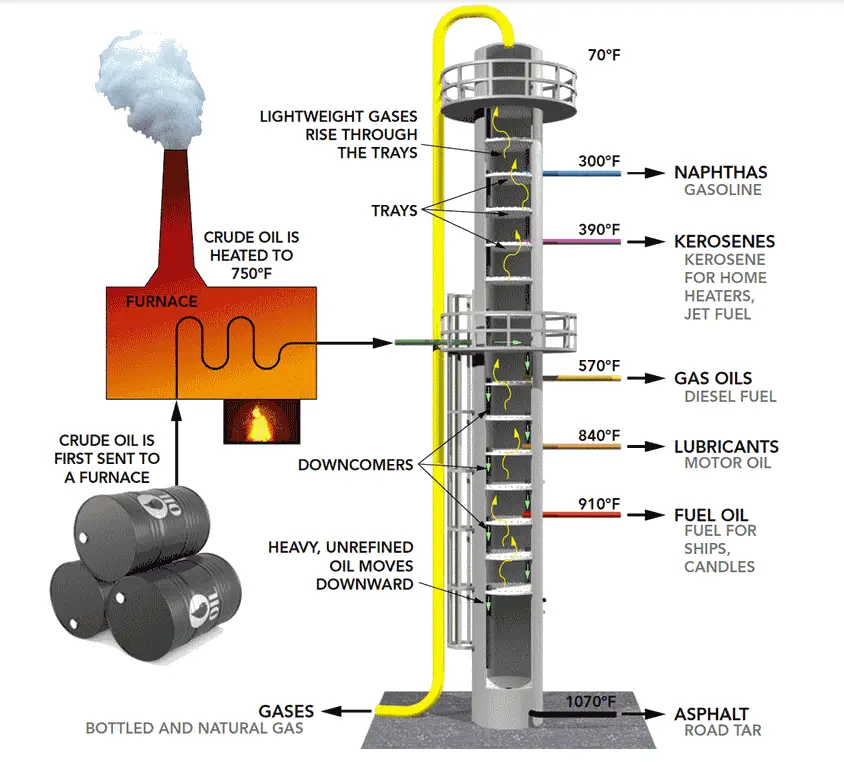

The genesis of petcoke traces back to the conclusive thermal cracking process undertaken within Coker units. These units play a pivotal role in disassembling the lengthy hydrocarbon chains present in petroleum residues, ultimately converting them into shorter, more manageable chains. Petroleum coke is also known as Refinery Coke.

The Birth of Petroleum Coke: From Crude Oil to Carbon

Petroleum coke is a byproduct that emerges during the oil refining process, specifically from the residue left behind after the distillation of crude oil. This residue, known as “resid” or “bottom-of-the-barrel,” is the source material from which petroleum coke is derived. The refining process removes lighter hydrocarbons from the crude oil, leaving behind heavier fractions which are then subjected to further processing. Fig. 1 below shows some typical examples of Petroleum Coke.

Distillation and Coking: The Transformation Process

The conversion of residual oil into petroleum coke involves a thermal decomposition process called coking. There are two primary methods of coking:

- Delayed Coking: This process involves heating the residual oil in large, cylindrical drums at elevated temperatures. As the oil breaks down, the carbon content in the residue solidifies into petroleum coke while releasing volatile gases and liquids.

- Fluid Coking: Fluid coking utilizes a fluidized bed reactor to heat the residual oil, resulting in the creation of petroleum coke and a mixture of gases and liquids.

Characteristics of Petroleum Coke

Petroleum coke comes in various forms, each with unique characteristics that make it suitable for specific applications. The most common types include:

- Needle Coke: Recognized for its exceptional electrical conductivity and mechanical properties, needle coke is a vital component in the production of graphite electrodes for electric arc furnaces and lithium-ion batteries.

- Fuel-Grade Petcoke: Used as a fuel source in power generation and cement kilns, fuel-grade petcoke is characterized by its high carbon content and low levels of sulfur and metals.

- Green Coke: Green coke constitutes the unprocessed feedstock employed in the production of calcined coke. This solid carbon residual stems from the oil refining procedure and is characterized by its elevated levels of moisture and volatile constituents.

- Calcined Petcoke: Calcination involves heating petroleum coke to high temperatures to remove volatile components, resulting in a product with enhanced properties such as higher carbon purity and improved density. Calcined petcoke is widely used in the production of anodes for the aluminum industry and as a raw material in the manufacturing of carbon products.

Specification of Petroleum Coke

Specifications for petroleum coke outline the characteristics and properties that define its quality and suitability for various industrial applications. These specifications serve as essential guidelines to ensure that the petcoke meets the desired standards and can be effectively used in processes such as energy generation, manufacturing, and more. Here are some of the key specifications that are typically considered for petroleum coke:

- Moisture Content: The moisture content of petcoke is a crucial parameter, as excessive moisture can affect its combustion efficiency and performance. Low moisture content is generally preferred for most applications.

- Volatile Matter: The volatile matter in petcoke contributes to its combustion behavior and can impact emissions. Certain applications require specific levels of volatile matter to ensure optimal performance and environmental compliance.

- Sulfur Content: Sulfur content is a critical specification due to its environmental implications. High sulfur content can lead to increased emissions of sulfur dioxide, which contributes to air pollution. Thus, lower sulfur content is often preferred, especially for applications with strict emission regulations.

- Ash Content: The ash content of petcoke is a measure of the inorganic material present. Higher ash content can lead to increased slagging and fouling in combustion processes, potentially affecting equipment performance.

- Fixed Carbon: Fixed carbon content is an important indicator of the energy content and combustion efficiency of petcoke. Higher fixed carbon content generally corresponds to higher calorific value and better combustion characteristics.

- Calorific Value: The calorific value or heating value of petcoke indicates the amount of energy it can release upon combustion. This is crucial for applications such as energy generation and industrial heating.

- Particle Size Distribution: The particle size distribution of petcoke can influence its handling, storage, and combustion properties. Different applications may require specific particle size ranges.

- Hardgrove Grindability Index (HGI): HGI is a measure of the grindability or ease of pulverizing petcoke. It is important for applications that involve grinding or pulverizing the material.

- Vanadium and Nickel Content: These trace elements can have an impact on the performance of catalysts and equipment in certain applications. Lower levels are generally preferred, particularly in applications like fluid catalytic cracking (FCC) units.

- Metal Content: Metal impurities, such as iron, can influence the reactivity and behavior of petcoke. Specific applications may have limits on metal content to prevent adverse effects.

The following table provides a typical specification of Petroleum Coke

| Specification | Range | Method |

|---|---|---|

| Moisture Content | 2% max | ASTM D3302 |

| Volatile Matter | 8 – 14% | ASTM D3175 |

| Sulfur Content | 1 – 5% | ASTM D4294 |

| Ash Content | 0.2 – 1.5% | ASTM D3174 |

| Fixed Carbon | 85% min | Calculated |

| Calorific Value | 14,000 – 15,500 Btu/lb | ASTM D5865 |

| Particle Size (Sieve) | 0.2 – 3.0 mm | ASTM D5003 |

| HGI (Hardgrove Index) | 40 – 60 | ASTM D409 |

| Vanadium Content | 100 ppm max | ASTM D5056 |

| Nickel Content | 50 ppm max | ASTM D5056 |

| Metal Content (Fe) | 300 ppm max | ASTM D5609 |

Applications Across Industries

Petroleum coke finds its way into an array of industries, playing a crucial role in powering economies and driving technological advancements. Some of the prominent applications include:

Petroleum coke, with its diverse characteristics and properties, finds application across several industries and sectors. Its versatility, ranging from energy generation to manufacturing, makes it a valuable resource in various processes. Here are some prominent applications of petroleum coke:

1. Energy Generation:

- Fuel for Power Plants: High-energy content and relatively low cost make petroleum coke a preferred fuel in power plants, aiding in electricity generation.

- Co-firing with Coal: Petcoke can be co-fired with coal in power plants to enhance combustion efficiency and reduce greenhouse gas emissions.

2. Industrial Processes:

- Cement Manufacturing: Petcoke serves as an alternative fuel and raw material in cement kilns, providing high heat input and reducing fossil fuel consumption.

- Steel Production: As a reducing agent, petcoke aids in the smelting process in blast furnaces and electric arc furnaces, contributing to steel production.

3. Aluminum Industry:

- Anode Production: Calcined petcoke is used as a key component in the production of anodes for aluminum smelting, ensuring efficient electrolytic processes.

4. Carbon and Graphite Industries:

- Graphite Electrodes: High-quality needle coke derived from petcoke is essential in manufacturing graphite electrodes for electric arc furnaces and lithium-ion batteries.

- Carbon Products: Calcined petcoke finds application in the production of carbon products such as brake linings, carbon brushes, and more.

5. Refractories:

- Raw Material: Petroleum coke is used as a raw material in the manufacturing of refractory bricks and other refractory materials due to its high-temperature resistance.

6. Foundry Industry:

- Reducing Agent: Petcoke can be employed as a reducing agent in foundries during the melting of metals and alloys.

7. Glass Industry:

- Fuel Source: Petcoke’s high calorific value makes it suitable for use as a fuel in glass manufacturing furnaces.

8. Chemical Industry:

- Feedstock: In certain chemical processes, petcoke can serve as a feedstock for the production of various chemicals.

9. Petcoke Gasification:

- Advanced Technology: In some regions, petcoke is used as a feedstock for gasification processes, converting it into syngas for further chemical or energy applications.

10. Waste-to-Energy Applications:

- Co-firing in Waste-to-Energy Plants: In waste-to-energy facilities, petcoke can be co-fired with other waste materials to generate heat and electricity.

Differences between Petroleum Coke and Coal: Pet Coke vs Coal

Petroleum coke (petcoke) and coal are both carbon-rich solid fuels, but they have distinct origins, compositions, and characteristics. Here are some key differences between petroleum coke and coal:

1. Origin:

- Petroleum Coke: Petcoke is a byproduct of the oil refining process. It is formed from the residual material left over after the distillation of crude oil. Petcoke is produced in refineries and is a carbon-rich material.

- Coal: Coal is a fossil fuel that is primarily formed from the remains of plants that lived and died millions of years ago. It is found in underground coal seams and is extracted through mining.

2. Composition:

- Petroleum Coke: Petcoke is composed mainly of carbon, with varying amounts of hydrogen, sulfur, nitrogen, and other elements. It also contains trace amounts of metals like vanadium and nickel.

- Coal: Coal is composed of carbon, hydrogen, oxygen, nitrogen, sulfur, and other elements. The specific composition of coal can vary widely depending on its type and source.

3. Sulfur Content:

- Petroleum Coke: The sulfur content of petcoke can vary widely, with some grades having low sulfur content and others having high sulfur content.

- Coal: Coal can also have varying sulfur content, with some types of coal containing higher sulfur levels, leading to potential environmental issues when burned.

4. Energy Content:

- Petroleum Coke: Petcoke generally has a higher energy content (calorific value) compared to coal on a per-unit-mass basis.

- Coal: The energy content of coal can vary depending on its type and grade.

5. Applications:

- Petroleum Coke: Petcoke is often used as a fuel source in power plants, cement kilns, and industrial processes. It is also utilized in the production of carbon and graphite products, including graphite electrodes for various industries.

- Coal: Coal has a wide range of applications, including energy generation (electricity and heat), industrial processes, steel production, and more.

6. Environmental Impact:

- Petroleum Coke: Burning petcoke can release greenhouse gases, sulfur dioxide, and other pollutants into the atmosphere. Its use is associated with air quality and environmental concerns, particularly when high-sulfur petcoke is burned.

- Coal: Coal combustion releases carbon dioxide, sulfur dioxide, nitrogen oxides, and particulate matter into the air. The environmental impact of coal is well-documented and has led to efforts to reduce its use and improve emissions control technologies.

7. Production Process:

- Petroleum Coke: Petcoke is a byproduct of the oil refining process, specifically from the coking of residual oil.

- Coal: Coal is mined from underground or surface mines and undergoes various processing steps before it is used as a fuel.

The major differences between coal and petroleum coke are reproduced below in Table 2.

| Aspect | Coal | Petroleum Coke |

| Origin | Fossil fuel formed from ancient plant remains | A byproduct of the oil refining process |

| Composition | Carbon, hydrogen, oxygen, nitrogen, sulfur | Mainly carbon, with varying elements (hydrogen, sulfur, nitrogen, metals) |

| Energy Content | Varies with coal type and grade | Generally higher energy content compared to coal |

| Applications | Energy generation, industrial processes, steel production, heating, etc. | Fuel in power plants, cement kilns, carbon, and graphite product manufacturing |

| Environmental Impact | Releases CO2, SO2, NOx, particulates | Releases CO2, SO2, NOx, particulates, potential environmental concerns |

| Production Process | Mined from underground or surface mines, various processing steps | A byproduct of the oil refining, produced during the coking process |

Environmental Considerations and Future Outlook

While petroleum coke serves various essential functions, its production and use raise environmental concerns. Emissions from burning petcoke, especially the high sulfur content in some grades, contribute to air pollution and can have adverse effects on air quality and human health. As industries move towards cleaner and more sustainable practices, the use of petroleum coke is being scrutinized, and research is being conducted to develop greener alternatives and more efficient utilization methods.

Conclusion

Petroleum coke, a hidden gem within the world of industrial byproducts, plays a vital role in diverse sectors, from energy production to manufacturing. Its varied forms cater to different applications, enabling industries to function efficiently and effectively. As we navigate the path toward a more sustainable future, it is imperative to strike a balance between harnessing the benefits of petroleum coke and addressing the environmental challenges it poses. As research and innovation progress, we can anticipate the evolution of petroleum coke’s role in our ever-changing industrial landscape.