In our quest for sustainable living and reducing our carbon footprint, heat pumps have emerged as a remarkable solution. These versatile devices have revolutionized the way we heat and cool our homes, offering efficient and eco-friendly alternatives to traditional heating and cooling systems. In this article, we will dive into the world of heat pumps, exploring their working principles, benefits, and their potential to transform the way we use energy in our daily lives.

What is a Heat Pump?

A heat pump is a mechanical device that transfers heat from one location to another using a small amount of energy. Unlike conventional heating and cooling systems, which generate heat or cool air directly, heat pumps simply move heat from one place to another. By extracting heat from the air, ground, or water, heat pumps can provide both heating and cooling functions, making them highly versatile and energy-efficient.

Components of a Heat Pump

A heat pump consists of several key components that work together to facilitate the transfer of heat. The main components of a typical heat pump system include:

- Evaporator: The evaporator is responsible for absorbing heat from the source medium, such as air, water, or the ground. It contains a coil through which a refrigerant passes, evaporating as it absorbs heat from the surrounding medium.

- Compressor: The compressor plays a vital role in the heat pump cycle. It receives the low-pressure, low-temperature vaporized refrigerant from the evaporator and compresses it, increasing both its temperature and pressure. This process raises the energy level of the refrigerant, preparing it for the next stage of heat transfer.

- Condenser: The condenser facilitates the release of heat from the high-pressure, high-temperature refrigerant. It consists of a coil or series of tubes that allow the refrigerant to give off heat to the desired space or environment. As the refrigerant condenses back into a liquid state, it transfers the accumulated heat to the surroundings.

- Expansion Valve: The expansion valve acts as a metering device and pressure regulator in the heat pump system. It regulates the flow of refrigerant from the high-pressure side (condenser) to the low-pressure side (evaporator). By creating a pressure drop, the expansion valve enables the refrigerant to expand, cool down, and prepare for the evaporation process in the evaporator.

- Reversing Valve: The reversing valve of the heat pump helps to reverse the flow of refrigerant. It allows the heat pump system to operate in the opposite direction and switch between heating and cooling.

- Refrigerant: The refrigerant is a specially formulated fluid with excellent heat transfer properties. It undergoes phase changes (evaporation and condensation) during the heat pump cycle, absorbing and releasing heat in the process. Common refrigerants used in heat pumps include environmentally friendly options like R-410A and R-32.

- Air Handler or Fan: In air-source heat pumps, an air handler or fan is used to circulate the air across the evaporator and condenser coils. The air handler helps distribute the heated or cooled air throughout the building or space being conditioned.

Additional components may also be present in more complex heat pump systems, depending on the specific configuration and features. These can include filters, sensors, control panels, and auxiliary heating elements for supplemental heating when required.

Working Principles of Heat Pump

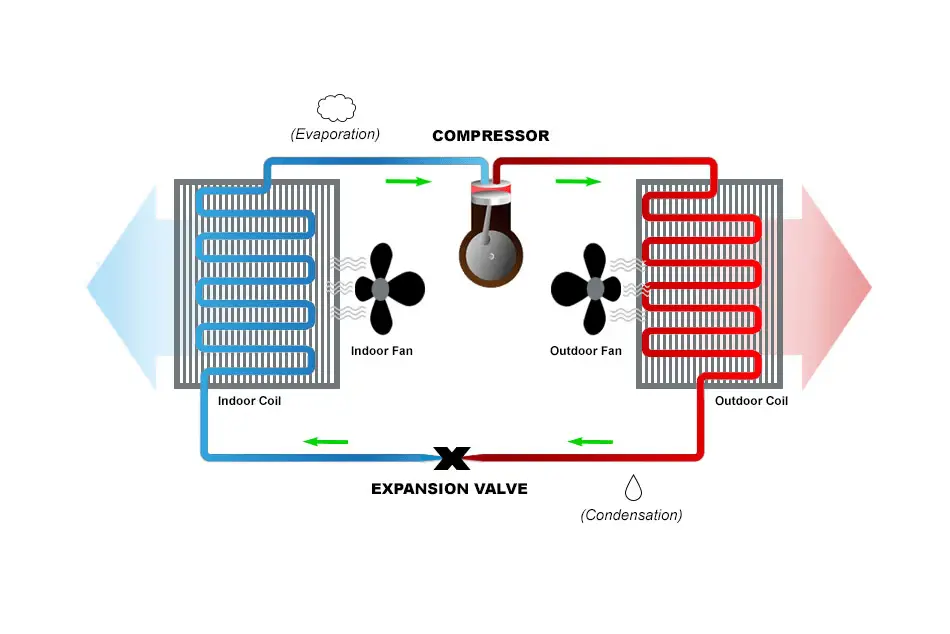

Heat pumps work based on the principles of thermodynamics, utilizing the properties of refrigerants to transfer heat. The primary components of a heat pump system include the evaporator, compressor, condenser, and expansion valve. Here’s a simplified overview of how a heat pump works:

- Evaporation: The refrigerant evaporates at a low temperature, absorbing heat from the surrounding air, ground, or water.

- Compression: The compressor raises the pressure and temperature of the refrigerant, further increasing its heat content.

- Condensation: The hot refrigerant passes through the condenser, releasing heat to the indoor or outdoor environment.

- Expansion: The refrigerant, now in a cool, low-pressure state, returns to the evaporator to restart the cycle.

Heating and Cooling Applications

One of the most significant advantages of heat pumps is their ability to provide both heating and cooling. During colder months, heat pumps extract heat from the outside environment and transfer it indoors for heating purposes. Conversely, during warmer months, the cycle reverses, as heat pumps remove heat from the indoor space and release it outdoors, effectively cooling the area.

How does a Heat Pump Cool and Heat?

A heat pump can both cool and heat by utilizing the same basic refrigeration cycle, but with a reversing valve that allows for the reversal of the refrigerant flow. Here’s a breakdown of how a heat pump operates for both cooling and heating modes:

Heat Pump Working for Cooling Mode:

- Evaporator: In cooling mode, the heat pump absorbs heat from the indoor space. The refrigerant flows through the evaporator coil, which is located inside the building. As warm indoor air passes over the coil, the refrigerant evaporates, absorbing the heat from the air.

- Compressor: The low-pressure, low-temperature vaporized refrigerant is then compressed by the compressor. This compression increases the temperature and pressure of the refrigerant, raising its energy level.

- Condenser: The hot, high-pressure refrigerant now moves to the condenser coil, located outside the building. As the outdoor air passes over the condenser coil, the refrigerant releases heat to the outdoor environment, cooling down and condensing into a liquid state.

- Expansion Valve: After the refrigerant leaves the condenser, it passes through the expansion valve, where it undergoes a pressure drop. This drop in pressure causes the refrigerant to cool down further, preparing it for the evaporator coil and restarting the cycle. The schematic in Fig. 1 (Image Courtesy: https://www.carrier.com/residential/en/us/products/heat-pumps/what-is-a-heat-pump-how-does-it-work/ ) clearly explains the working of heat pumps.

Heat Pump Working in Heating Mode:

- Reversing Valve: To switch to heating mode, the reversing valve in the heat pump is activated, allowing the refrigerant flow to reverse its direction.

- Evaporator and Condenser: In heating mode, the outdoor coil becomes the evaporator, absorbing heat from the outside air. The indoor coil, now acting as the condenser, releases heat to the indoor space.

- Compressor and Expansion Valve: The refrigerant flows through the compressor, which raises its temperature and pressure, and then to the expansion valve, where it undergoes a pressure drop and cools down.

- Heat Distribution: The heated refrigerant in the indoor coil transfers its heat to the air circulating through the air handler or fan. The warm air is then distributed throughout the building, providing heating.

By reversing the flow of the refrigerant and utilizing the heat transfer process, a heat pump can alternate between cooling and heating modes, making it a versatile system for maintaining desired indoor temperatures throughout the year. This ability to provide both heating and cooling makes heat pumps an efficient and cost-effective solution for temperature control in residential and commercial settings.

Types of Heat Pumps

Air-Source Heat Pumps:

These heat pumps extract heat from the outdoor air and transfer it indoors during winter. In summer, the cycle reverses, expelling heat from indoors to the outside. They are easy to install, cost-effective, and suitable for moderate climates.

Ground-Source Heat Pumps (Geothermal):

These heat pumps harness the relatively stable temperature of the ground. They circulate fluid through underground pipes, extracting heat in winter and dissipating heat in summer. Geothermal heat pumps are highly efficient but require more installation effort and initial investment.

Absorption Heat Pumps:

Absorption heat pumps are a type of heat pump that uses a heat source to drive the refrigeration cycle instead of an electric compressor. They operate based on the principle of absorption refrigeration and can provide both heating and cooling functions.

Benefits of Heat Pumps

Energy Efficiency:

Heat pumps are significantly more energy-efficient than traditional heating and cooling systems since they move heat rather than generate it. They can achieve energy savings of up to 50% compared to conventional methods.

Reduced Carbon Footprint:

Heat pumps operate on electricity and can utilize renewable energy sources, resulting in a significant reduction in greenhouse gas emissions compared to fossil fuel-based systems.

Cost Savings:

Although the upfront cost of installing a heat pump may be higher, the long-term energy savings and potential government incentives can offset the initial investment, leading to considerable cost savings over time.

Versatility and Convenience:

Heat pumps offer the flexibility of providing both heating and cooling functions, eliminating the need for separate systems. They can also be integrated with other technologies, such as solar panels, further enhancing their energy efficiency.

What is a Water Heating Heat Pump?

A water heating heat pump, also known as a heat pump water heater (HPWH), is a specific type of heat pump designed to efficiently heat water for domestic use. It operates on the same principles as a traditional heat pump but focuses on providing hot water instead of heating or cooling indoor spaces. A water heating heat pump extracts heat from the surrounding air, ground, or water and transfers it to the water, resulting in an energy-efficient and cost-effective method of water heating.

It’s important to note that the performance of a water heating heat pump can vary depending on factors such as ambient temperature, humidity, and the location of the unit. However, when properly sized and installed in suitable conditions, water heating heat pumps can offer an efficient and reliable solution for meeting hot water needs while reducing energy consumption and costs.

What is Principle of Heat Pump?

The principle of a heat pump is based on transferring heat rather than generating it, utilizing the thermodynamic refrigeration cycle. It operates by moving heat from one location to another: in cooling mode, it extracts heat from the indoor air and releases it outside, while in heating mode, it absorbs heat from the outside air, ground, or water and transfers it indoors. This process involves a refrigerant that circulates through the system, undergoing compression to increase its temperature and pressure, then releasing or absorbing heat as it passes through coils. The refrigerant is then expanded, lowering its temperature and pressure, and the cycle repeats. By reversing the refrigerant flow, a heat pump can efficiently provide both heating and cooling, often with greater energy efficiency compared to conventional systems

What is a Mini Split Heat Pump?

A mini-split heat pump, also known as a ductless heat pump or ductless mini-split system, is a type of heat pump that provides both heating and cooling functions without the need for ductwork. It consists of two main components: an outdoor unit (condenser/compressor) and one or more indoor units (evaporator/fan coil). The indoor and outdoor units are connected by refrigerant lines, electrical wiring, and a conduit, allowing for the transfer of heat or cooling.

Here are some key features and characteristics of a mini-split heat pump:

- Ductless Design: Unlike traditional HVAC systems that rely on ductwork to distribute conditioned air, mini-split heat pumps are ductless. This makes them ideal for retrofitting older homes or buildings without existing ductwork or for areas where adding ducts would be impractical.

- Zone Heating and Cooling: Mini-split systems allow for zoned temperature control, enabling different rooms or areas to be heated or cooled independently. Each indoor unit is installed in its designated space and can be controlled individually, providing personalized comfort and energy efficiency.

- Installation Flexibility: Mini-split heat pumps offer flexible installation options. The indoor units can be mounted on walls, suspended from ceilings, or recessed into the ceiling, depending on the specific requirements and aesthetics of the space. The outdoor unit is typically placed outside the building.

- Energy Efficiency: Mini-split heat pumps are known for their energy efficiency. They utilize inverter-driven compressors that adjust their speed according to the heating or cooling demand, resulting in precise temperature control and reduced energy consumption.

- Heat Pump Operation: Mini-split systems work based on the same principles as other heat pumps. In heating mode, the outdoor unit extracts heat from the outside air and transfers it to the indoor unit(s) to provide warmth. In cooling mode, the process is reversed, with the heat pump absorbing heat from indoor air and releasing it outdoors.

- Remote Control and Smart Features: Many mini-split heat pumps come with remote control or smartphone apps, allowing for easy operation and temperature adjustments. Some models also offer advanced features like programmable timers, sleep modes, and Wi-Fi connectivity for convenient control and energy management.

- Quiet Operation: Mini-split heat pumps are designed to operate quietly, providing comfortable and noise-free environments.

Mini-split heat pumps are widely used in residential homes, commercial spaces, and even multi-zone applications like hotels or office buildings. Their compact size, installation flexibility, energy efficiency, and zoning capabilities make them a popular choice for efficient heating and cooling in a wide range of settings.

Advantages and Disadvantages of Heat Pumps

The major advantages and disadvantages of heat pumps are provided in table-1 below:

| Advantages | Disadvantages |

|---|---|

| High Energy Efficiency | Higher upfront cost compared to some systems |

| Provides both heating and cooling functions | Can provide hot water with a water-heating heat pump |

| Lower greenhouse gas emissions | Performance affected by extreme temperatures |

| Can be powered by renewable energy sources | Initial installation complexity in some cases |

| Energy savings and reduced utility bills | Regular maintenance and servicing required |

| Versatility in integration with other systems | May require additional space for an outdoor unit |

| Can provide hot water with a water heating heat pump | Some types may produce noise during operation |

Heat Pump vs Air Conditioner

The major differences between heat pumps and air conditioners are provided in Table 2 below:

| Parameter | Heat Pump | Air Conditioner |

|---|---|---|

| Function | Provides both heating and cooling functions | Provides cooling only |

| Operation | Reversible, can switch between heating and cooling modes | Operates in cooling mode only |

| Heating Source | Extracts heat from air, ground, or water | Does not provide heating |

| Cooling Source | Expels heat to the outside environment | Expels heat to the outside environment |

| Energy Efficiency | Highly energy efficient, can provide energy savings | Energy efficiency varies, may have lower efficiency |

| Seasonal Use | Suitable for year-round use in different climates | Primarily used during hot seasons |

| Installation | Can be more complex and may require additional components for heating functionality | Simpler installation |

| Energy Source | Can utilize renewable energy sources like solar power | Requires electricity |

| Cost | The initial investment may be higher, but long-term energy savings can offset costs | Lower initial cost |

| Environmental Impact | Lower greenhouse gas emissions, reduced carbon footprint | Higher energy consumption, increased environmental impact |

| Versatility | Can be integrated with other systems like solar panels for enhanced efficiency | Limited to cooling applications |

It’s worth noting that there are different types of air conditioners, such as window units, split systems, and central air conditioning, which may have variations in their features and capabilities. The table above provides a general comparison between heat pumps and air conditioners, focusing on the key differences.

Is a Heat Pump better than Air Conditioner?

A heat pump can be more versatile than a traditional AC because it functions as both a heating and cooling system, making it a year-round solution. It works by transferring heat rather than generating it, which can be more energy-efficient and cost-effective, especially in moderate climates. In contrast, a traditional AC is designed solely for cooling and may be more suitable for regions with intense heat and less need for heating. While heat pumps can be more efficient overall, their performance can decrease in very cold temperatures, potentially requiring a supplementary heating source. Thus, the choice between a heat pump and an AC largely hinges on your local climate, energy efficiency goals, and whether you need a combined heating and cooling solution.

Differences between a Chiller and a Heat Pump

The major differences between a heat pump and a chiller:

| Factors | Heat Pump | Chiller |

|---|---|---|

| Function | Provides heating and cooling functions | Provides a cooling function only |

| Heat Transfer | Transfers heat from one location to another | Removes heat from a process or space |

| Operating Temperature Range | Can provide heating or cooling across a wide temperature range | Typically operates in a lower temperature range for cooling purposes |

| Heating Source | Extracts heat from the air, ground, or water | N/A (Focuses on heat removal) |

| Cooling Source | Expels heat to the outside environment | Utilizes a cooling medium or source |

| Energy Efficiency | Energy-efficient operation with the ability to provide both heating and cooling | Focuses on efficient cooling processes |

| Heat Distribution | Transfers heat to the desired space or location | Removes heat from a specific process or space |

| Application | Used in residential, commercial, and industrial settings for temperature control | Primarily used in industrial processes, large buildings, or HVAC systems |

| Compressor Type | Can utilize various compressor types, including reciprocating, scroll, or rotary compressors | Typically uses larger centrifugal or screw compressors |

| Integration | Can be integrated with other systems, such as solar panels or smart home technologies | Integrated with cooling towers or cooling mediums for heat dissipation |

| Cost Considerations | The initial investment may vary depending on the system size and features | Generally more expensive due to larger cooling capacities and specialized components |

How are Heat Pumps Installed?

Heat pump installation involves several key steps to ensure efficient operation and optimal performance. First, a professional assesses the home or building to determine the appropriate type and size of the heat pump system based on factors such as the building’s size, insulation, and climate. Next, the installation begins with placing the outdoor unit in a suitable location with adequate clearance for airflow and access. For air-source heat pumps, the outdoor unit is connected to the indoor unit through refrigerant lines and electrical wiring. In the case of ground-source (geothermal) heat pumps, boreholes or trenches are dug to install the ground loop system, which is then connected to the indoor heat pump unit. The indoor unit, which can be a ducted or ductless system, is installed in a central location or distributed throughout the space. Finally, the system is thoroughly tested to ensure proper operation, with refrigerant levels and electrical connections checked to confirm everything is functioning correctly. Professional installation ensures that the heat pump operates efficiently and effectively throughout its lifespan.

Conclusion

Heat pumps have emerged as a game-changer in the world of energy-efficient heating and cooling. With their ability to transfer heat rather than generate it, they provide substantial energy savings and reduce our reliance on fossil fuels. As we strive to create a more sustainable future, heat pumps hold great promise for both residential and commercial applications, offering a greener and more efficient alternative to traditional HVAC systems. By embracing this innovative technology, we can take a significant step towards a cleaner and more sustainable world.