K-factor for incompressible liquid

One of the most typical questions asked by process or hydraulic engineers is what is the value of hydraulic resistance (K-factor) of piping component (fitting, valve, etc) and how to calculate it for different types of flow? This is one of the most fundamental questions we deal with in PASS/HYDRO SYSTEM, and I will be happy to share some knowledge and experience with it. And let’s start from the most simple aspect – K-factor for incompressible liquid.

Few References for K-Factor Calculation

The most often referenced document for minor pressure losses in the piping is Crane Technical Paper 410 (or simply Crane TP-410). Here you can buy the latest version:

https://store.flowoffluids.com/TP410-US.html

However, it is not the best or most comprehensive source of data on K-Factors! Another much more advanced and respectable world standard is the famous “Handbook of Hydraulic Resistance” by Russian Professor I.E. Idelchik. This book became a reference book for generations of piping hydraulic engineers. Please read what Trey Walters, the President of AFT, writes about Professor Idelchik and his book, in his blog: “How a Russian Hydraulics Handbook Gained the Respect of the American Nuclear Industry”.

The latest 4th English edition is available here:

https://www.begellhouse.com/ebook_platform/5877598576b05c67.html

Another worldwide acknowledged and must-have book is “Internal Flow Systems” by famous BHRA researcher D.S. Miller.

This book exists in different editions. We use the 2nd edition (from BHR Group), and it is still possible to buy it via Amazon or other online book stores. The latest 3rd edition is mentioned here https://www.mentor.com/products/mechanical/flomaster/don-miller/internal-flow-systems , but we failed to order it (for reasons unclear for us).

So PASS/HYDRO SYSTEM basically uses Idelchik K-Factors crossed-checked by Miller data. Moreover, I.E. Idelchik personally checked and tested some correlations for the initial version of PASS/HYDRO SYSTEM 40 years ago!

But this is only the top of the list of K-factor sources.

Another very useful and important source of information is IHS ESDU documents.

The related ESDU series are the following: – ESDU Fluid Mechanics, Internal Flow Series – ESDU Fluid Mechanics, Internal Flow (Aerospace) Series – ESDU Heat Transfer Series. Many interesting reviews and references are hidden there.

There also are some recent reviews – of which I especially like “PIPE FLOW. A Practical and Comprehensive Guide” by D.C. Rennels and H.M.Hudson”.

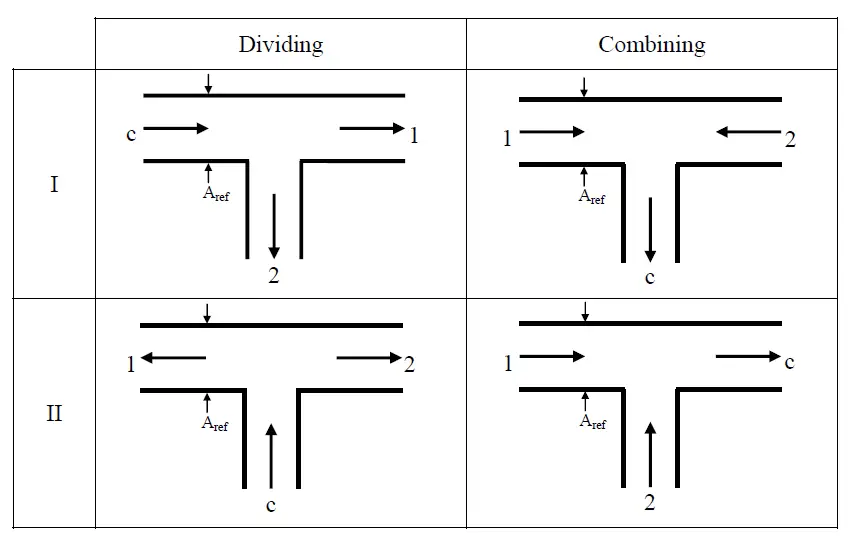

K-factors for T-Junction

Calculation of K-factors of T-junctions is one of the most complex topics, as their values depend on 1) ratio of run and side branch flow rates 2) ratio of side and run diameters 3) type of T-junctions (different variants of combining and dividing).

This subject was studied for almost a century, and still, there are holes! I will only consider 90-degree tees here and will give the most important references. Besides Idelchik and Miller (which give a good review on this – but not free from errors!) and 2 ESDU documents (ESDU 73022 and ESDU 73023), there are several classical experimental research works which we (and other specialists) use. Below are some most important of them.

First of all, classical articles by A. Gardel:

- Gardel A. 1957. Les Pertres de Charge dans les Écoulements au Travers de Branchements en Té. Bull. Tech. De la Suisse Romande 83:123-130, 144-148.

- Gardel A., Rechsteiner G.F. 1971. Les Pertres de Charge dans les Branchements en Te des Conduites de Section Circulaire. Publication No. 118, Ecole Polytechnique Federale de Lausanne, Lausanne, Switzerland.

Other classical works are articles by Hidesato Ito and his colleagues:

- Ito H., Imai K. Energy Losses at 90° Pipe Junctions. Proceedings of ASCE. Journal of Hydraulic Division. Vol. 99, No HY 9, 1973, pp.1353-1368.

- Kenji Oka, Takahito Nozaki, Hidesato Ito. Energy Losses Due to a Combination of Flow at Tees. JSME International Journal Series B. Vol. 39, No 3, 1996, pp. 489-498

- Kenji Oka, Hidesato Ito. Energy Losses at Tees with Large Area Rations. Transactions of ASME. Journal of Fluid Engineering. Vol. 127, No 1, 2005, pp.110-116

And at the beginning of this century, two students of Dr. Ahmet Selamet from the Ohio State University – Adam Christian and Jacques Paul – and other members of his research team made very good experimental work and filled some “holes” for symmetrical combining and dividing T-junctions:

- Christian A.M. The Effect of Interface Geometry on Flow Losses in Right-Angled Tee Junctions. MS Thesis. The Ohio State University. 2003. 113 pp.

- Christian, A., Selamet, A., Miazgowicz, K., and Tallio, K., “Flow Losses at Circular T-junctions Representative of Intake Plenum and Primary Runner Interface,” SAE Technical Paper 2004-01-1414, 2004.

- Paul J. Effect of Interface Geometry on Dividing and Combining Flow Losses in Right-Angled Tee Junctions. MS Thesis. The Ohio State University. 2005. 158 pp.

- Paul, J., Selamet, A., Miazgowicz, K., and Tallio, K., “Combining Flow Losses at Circular T-junctions Representative of Intake Plenum and Primary Runner Interface,” SAE Technical Paper 2007-01-0649, 2007.

Of course, this is only the tip of the iceberg! Minor losses for non-circular pipes, for compressible flow and multiphase flow, are other huge topics. And there are still lots of holes in our knowledge… But more about this and other topics in future articles!

So please join us in our journey for dark and secret places and hidden treasures of piping hydraulics!

Few more Resources for you..

Stress Analysis using PASS/START-PROF

Process Design related articles

Piping Design and Layout

About the Author: Leonid Korelstein (LinkedIn) – VP on R&D of PSRE Co (LinkedIn), and one of the leaders of PASS Suite (LinkedIn, Facebook) team. He is also the Product Manager of PASS/HYDROSYSTEM (LinkedIn group), PASS/RELIEF and PASS/INSULATION software. Leonid has Ph.D. in Mechanics and Mathematics and is Associate Professor (for Chemical Plant design and simulation software) in Mendeleev Chemical University, member of AIChE, active participant of DIERS, EDUG, and TUFFP research communities, co-author of AIChE CCPS GPREH book and Russian GOST 12.2.085-2017 standard for pressure relieve systems sizing. He is also an active member of the ASSESS Initiative.

good

good article