Nickel is a pure chemical element of the periodic table. It is represented by the symbol Ni and its atomic number is 28. Nickel is a transition metal in the d-block with a high boiling point (14530C). It is ductile and exhibits magnetic properties at room temperature. First discovered in the 1700s, nickel is used as a catalyst for various chemical reactions and is one of the main alloying elements in stainless steel. Nickel in Stainless Steel is a widely used constituent.

More than 66% of globally produced nickel is used to manufacture stainless steel alloy. Nickel in stainless steel improves formability, weldability, and ductility. Nickel-containing stainless steel is suitable for high-temperature applications. They provide very good corrosion resistance and remain ductile at low temperatures. In certain applications, nickel increases the corrosion resistance of stainless steel. The importance of nickel in stainless steel can be easily understood from the fact that nickel-containing stainless steel grades make up more than 75% of global stainless steel production.

Role of Nickel in Stainless Steel

There are several benefits that come with the addition of nickel in stainless steel.

The addition of Nickel increases the toughness of stainless steel. In general, chromium addition is steel decreases the toughness. So, that decrease in toughness is compensated by the addition of Nickel. Ferromagnetism in steel is not desirable in certain applications. The chromium addition induces ferromagnetism. The proper addition of Nickel helps in countering such problems.

Nickel in stainless steel work as the austenitic stabilizer. Nickel addition in steel functions to stabilize tough and ductile, FCC austenitic structure. Conventional steel has a body-centered cubic crystal known as a ferritic structure. Roughly 8% nickel can stabilize the austenitic structure at room temperature. This is the reason that most stainless steel grades (Example 304 grade) contain 8 percent nickel. In the early twentieth century, this composition (18% Chromium and 8% Nickel) was one of the first to be developed in the history of stainless steel.

In recent times, Manganese and Nitrogen is used to form austenitic structures. However, still, a small percentage of nickel is deliberately added to all the high-manganese austenitic grades commercially available today. Even the duplex stainless steel grades contain 1 percent or more nickel.

Nickel is also known to reduce the ductile-to-brittle transition temperature. This is the temperature below which the stainless steel or alloys have a tendency to convert into brittle. However, there are other parameters like grain size and other alloying elements that affect ductile-to-brittle transition temperature.

Even all high-strength precipitation-hardening stainless steel grades also contain nickel at an appreciable amount.

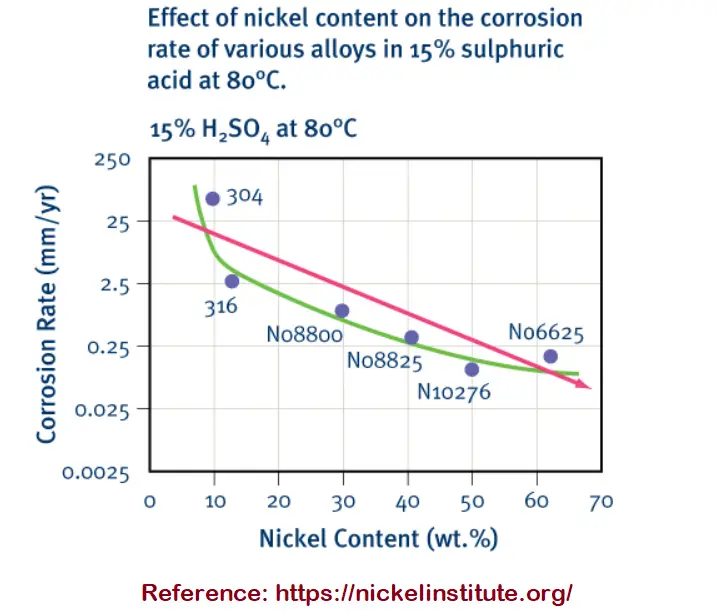

An increase in nickel addition in stainless steel increases the corrosion resistance. Nickel in stainless steel reduces the active corrosion rate in crevice corrosion. The following image shows the effect of increasing nickel content in reducing the corrosion rate in a 15 percent sulphuric acid solution at 80° C. However, note that various other alloying additions, too, affect the corrosion rate.

Properties of Nickel Containing Stainless Steels

Nickel-containing stainless steels provide various unique properties like

- Good weldability

- High toughness

- Good formability

- High-temperature properties

- Good Corrosion resistance

- Good surface finish

- Sustainability

Is nickel in stainless steel harmful?

Nickel-containing Stainless Steel is widely used in food and beverage industries for quite a long time. Easy formability, superb corrosion resistance, and excellent durability make them an ideal choice for cookware. Due to various health concerns raised over the recent past stainless steel is also believed to be harmful due to the presence of nickel in it. But studies have shown that unless the stainless steel is of poor quality, nickel will be soluted in a very small amount that is not in poisonous level to humans. So high-quality 304 or 316-grade stainless steel does not pose a severely bad effect on human health.

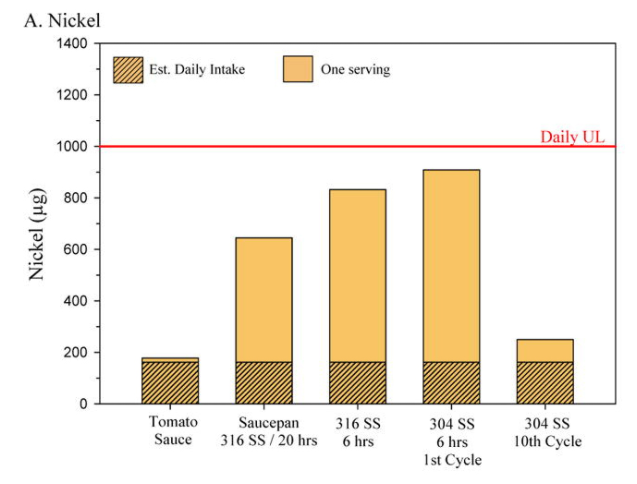

The following image from the U.S. National Library of Medicine shows that the amount of nickel intake due to the use of nickel-containing stainless steel is much lower than the tolerable intake limit of daily consumption.

Thank you, sir, very good information regarding the importance of Ni in SS and its properties.

Very good topic.

Very informative article sir.

Thanks for sharing it. I make customized jewelry and I try to use mainly stainless steel for it’s durability, so I was looking for knowing what is it exactly that I am selling to people. Very informative article!

Anup! Hey bro, I have to say, you have some of the best articles on piping, welded pipe, pipe metallurgy, pipe support, etc. And the way its written. Literally, it’s as if I were thinking it, or talking about the same thing. So, Great Job Brother!. Keep Up The Great Work.

Great 👌 post.

Can I get the PDF notes.

Thanks