Pipe fittings play a crucial role in the plumbing and piping industry, enabling the connection and flow of fluids within various systems. Among these fittings, pipe ferrules are essential components that ensure leak-proof and secure connections. In this comprehensive guide, we will delve into the world of pipe ferrules, exploring their uses, types, materials, installation methods, and the benefits they offer.

What is a Pipe Ferrule?

A pipe ferrule, also known as a compression ferrule fitting or compression ferrule sleeve, is a small cylindrical ring or collar made from various materials, including brass, stainless steel, copper, and plastic. It is used to create a tight, leak-proof connection between pipes, tubes, or hoses. The ferrule, along with other components like nuts and inserts, work together to create a secure and reliable joint.

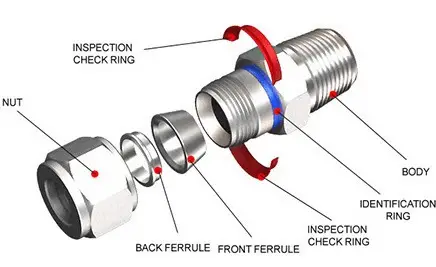

Pipe ferrules come in a range of sizes. Larger pipe ferrules are crafted with specialized hardening processes, enhancing their leak resistance and ability to securely hold tubes even under elevated pressure conditions. Fig. 1 below shows some typical ferrule fittings:

Components of a Pipe Ferrule

Ferrule fittings typically consist of several components that work together to create a robust connection. These components include:

- Front Ferrule: This part of the ferrule creates a seal by compressing against the fitting body.

- Back Ferrule: The back ferrule grips the tubing, enhancing the connection’s strength and stability.

- Fitting Body: The body holds the ferrules in place and facilitates the connection.

- Nut: The nut is used to tighten the ferrules and secure the connection.

Pipe Ferrule Materials

Ferrule fittings are available in a range of materials to accommodate different applications and environments. Common materials include:

- Stainless Steel: Known for its corrosion resistance, making it suitable for harsh environments.

- Brass: Offers good corrosion resistance and is often used in less demanding applications.

- Copper: Used in industries such as HVAC and refrigeration due to its excellent thermal conductivity.

- Plastic: Provides chemical resistance and is lightweight, making it suitable for certain fluid handling applications.

- Aluminum alloy

- Cast steel

- Ceramic

- Glass

Ferrule material is selected on a variety of factors such as material durability, connector mating frequency, surface finish over time, cost, and the material’s ability to retain end-face geometry.

Ferrule Fitting Sizes

Ferrule fittings come in various sizes and dimensions to fit different tubing and pipe sizes. The sizes are typically specified using standard measurements, such as inches or millimeters, and are designed to match industry standards. Common sizes range from 1/8 inch to larger sizes suitable for industrial applications.

Types of Pipe Ferrules

There are two types of ferrules; Single ferrule and double ferrule.

Single Ferrule:

Within single ferrule fittings, the ferrule’s tip serves a dual role. Firstly, it grips the tube by embedding itself, while also acting as a sealing element for the coupling body. It’s worth noting that single-ferrule fittings possess a lower pressure rating when compared to their twin-ferrule counterparts. Manufacturers meticulously design these ferrule fittings to align with operators’ preferences and to ensure user-friendly installation.

Twin or Double ferrule:

Twin or double ferrule fittings consist of front and back ferrules. In these fittings, the back ferrule provides gripping action, while the front ferrule ensures a reliable seal. The double ferrule also referred to as a two-ferrule system, is accessible in various materials. Its dimensions match those of single ferrule fittings. The robust mechanical grip design of double ferrule fittings ensures a flawless connection. These fittings are versatile, suitable for tubing of different diameters and hardness levels.

Again Based on the connection process, the following types of pipe ferrules are found:

- Compression Ferrules: These ferrules are commonly used for connecting copper, plastic, or stainless steel pipes. They consist of a compression nut, body, and ferrule. When the nut is tightened, it compresses the ferrule against the pipe, creating a tight seal.

- Swage Ferrules: Swage ferrules are used to create a permanent connection between pipes or cables. They are often used in industries such as aerospace and marine, where reliability is of utmost importance. Swaging involves deforming the ferrule to grip the pipe tightly.

- High-Pressure Ferrules: These ferrules are designed to withstand high-pressure applications, making them suitable for hydraulic systems, oil and gas pipelines, and industrial machinery.

- Push-to-Connect Ferrules: These innovative ferrules allow for quick and easy installation without the need for special tools. They are commonly used in plumbing and pneumatic systems.

Installation Process

Installing pipe ferrules requires precision and care to ensure a proper connection. Here’s a step-by-step guide to installing compression ferrules, one of the most common types:

- Cutting and Preparing the Pipe: Measure and mark the pipe to the desired length. Use a pipe cutter to create a clean, square cut.

- Insert the Ferrule: Slide the Ferrule onto the pipe, ensuring it sits in the correct position where the connection will be made.

- Insert the Pipe: Insert the pipe into the fitting until it reaches the base. Make sure it is fully seated.

- Tighten the Nut: Thread the compression nut onto the fitting and tighten it by hand until snug.

- Tighten with Wrench: Use a wrench to tighten the nut further, creating a strong compression force on the ferrule. Be careful not to overtighten, as this could damage the ferrule or pipe.

- Check for Leaks: Turn on the system and check for any leaks. If leaks are detected, try slightly tightening the nut. Avoid excessive force, as this may cause damage.

Benefits of Using Pipe Ferrules

Leak Resistance: Pipe ferrules provide a secure and leak-proof connection, ensuring the integrity of fluid and gas systems.

- Versatility: Ferrules can be used with various types of pipes, including copper, plastic, stainless steel, and more.

- Easy Installation: Compression and push-to-connect ferrules offer straightforward installation, reducing the need for complex tools or soldering.

- Reusable: Compression ferrules are generally reusable, making them a cost-effective option.

- High-Pressure Applications: Specialized ferrules can handle high-pressure environments, contributing to the safety and efficiency of systems.

- Clean Appearance: Ferrule connections are tidy and visually appealing, making them suitable for visible piping in homes and commercial spaces.

Applications of Pipe Ferrules

A pipe ferrule fields application in various industries such as:

- Appliance

- Automotive

- Beverage

- Compressed-gas

- Electrical & electronics

- Farm and lighting industries

- Fiber optics

- Fire suppression

- Furniture

- Hardware

- Instrumentation

- Lawn and garden instruments

- Welding, etc.

Conclusion

Pipe ferrules are essential components in the world of plumbing and piping, offering secure connections, leak resistance, and ease of installation. Their versatility and ability to handle various types of pipes and applications make them indispensable in industries ranging from residential plumbing to heavy-duty industrial systems. Understanding the different types of ferrules and their installation process empowers professionals and DIY enthusiasts alike to create reliable and efficient piping systems.