Man-hour is the unit for estimating the time required for completing an activity of a project. Man-hours estimation is a crucial activity for winning projects. Labor cost constitutes a considerable amount of the project cost and the same is calculated by estimating man-hours.

Importance of Man-Hour Estimation

Estimating the project man-hour is a very critical activity and should be done very accurately. Any mistake in this action may result in a huge loss to any organization. If more man-hours are quoted then the project may not be awarded to the organization and if less man-hour is quoted then the design company may incur a cost in the long run. So one should make a competitive man-hour estimate considering all activities.

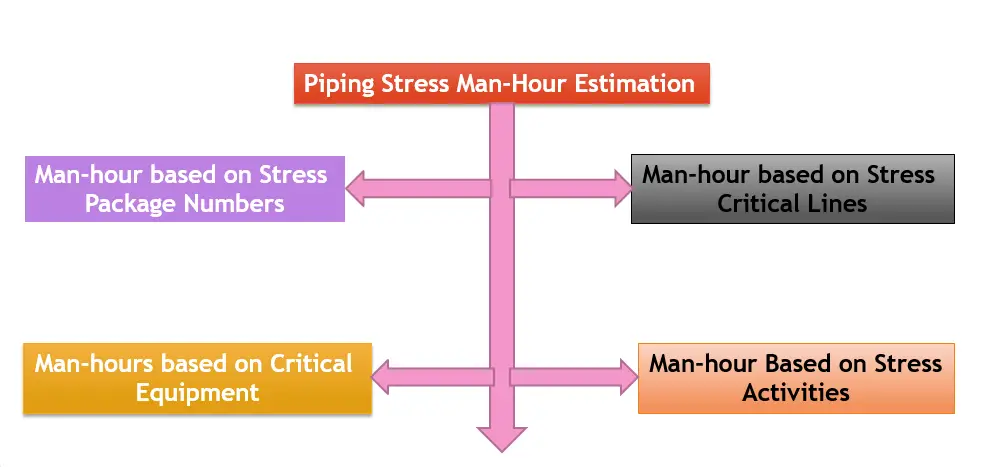

Piping stress analysis is a very important activity in piping design and separate man-hours must be claimed from the client for this. Normally, on average, piping stress analysis-related activities require roughly 8-12% of the total piping man-hour. The man-hour estimation is done either during the project bidding activity or during the initial phase of any project. So hardly any firm data is available while man-hour estimation is done. So sufficient cushion needs to be added for rework activity. The following write-up will provide a guideline for the piping stress man-hour estimation process for any project. Broadly, there are three practices for man-hours calculation that are followed in established EPC organizations. They are:

1. Estimating Piping Man-hour based on Stress Packages

Normal practice is to estimate the number of stress packages from available P&ID, then multiply the same by some constant value (decided based on experience). Few organizations divide stress packages into three groups,

- highly critical stress systems

- moderately critical stress systems and

- lower critical stress systems

Lets for example if for a project 250 stress packages are estimated out of which 20 are highly critical, 100 are moderately critical, and rest 130 are lower critical then manhour estimates will be =1.2 X (20×50 + 100×40 + 130×30) =10680 considering 50 man-hours for a highly critical package, 40 man-hours for a moderately critical stress package and 30 man-hours for lower critical stress package. The total value is increased by 20% as the data is not firm.

2. Calculating Piping Man-hour based on Stress Critical Lines

In this method, the total number of stress critical lines is estimated from the existing P&ID. Then that value is multiplied by a factor (Normally 12 to 18 depending on the experience of the existing organization). For example, if the project mentioned above contains 4 stress critical lines (you have to calculate critical lines from P&ID) per stress system on average, then the total number of stress critical lines is 250×4=1000. So total piping man-hours estimated would be approximately 1000 x 12=12000.

3. Estimating Man-hours based on Critical equipment

This method is somewhat similar to the method mentioned in point no 1. In this method, the total number of equipment is calculated from the P&ID. All equipment is then categorized into three groups

- Highly critical equipment like Turbines, Compressors, High-temperature Reactors, Furnaces, etc.

- Moderately critical equipment like Air Fin Cooler, Pumps, High-temperature Columns, Heat exchangers, etc. and

- Lower Critical equipment like Low-temperature Columns, Heat exchangers, etc.

Then the number of equipment is multiplied by the same predecided (based on experience) factors to get the total man-hours.

Documents required for Man-Hour calculation

In any of the above situations the following input documents are required at a minimum:

- P&ID (If not available then man-hour estimation can be done based on preliminary P&ID or FEED P&ID)

- Line List, if available

- Equipment list, if available

However, in my opinion, one should look into the exact scope of work (activity-wise) by the stress department. Then one should consider reasonable man-hour (which normally takes based on experience) for each activity. And finally, add all the man-hours of each activity together to get the final man-hour. This way one could get the man-hour close to the actual.

4. Man-hour Estimation Based on Activities Performed

The first step will be to list out all the activities in the stress scope. For example from the initial start of any project broadly following stress activities have to be considered:

1. Study of Project Specifications and bid documents

2. Work Instruction and Specification preparation from bid documents if required

3. Pipe Rack Loading (Three or Four Stages)

4. Stress System definition from P&ID

5. Master Critical Line list preparation (Will be updated 3 to 4 times during project tenure)

6. Preliminary stress analysis before receipt of vendor equipment data (without proper documentation)

7. Final stress analysis after receipt of vendor equipment data (With proper documentation)

8. Spring datasheet and Spring Index preparation

9. Special support design

10. Datasheet preparation for miscellaneous items like an expansion joint, sway brace, strut, etc

11. Trunnion calculation

12. Review of Stress systems

13. Vendor communication

14. Interdepartmental communication with the Civil, Mechanical, and Process departments

15. Technical Bid Evaluation of Spring Hangers and Special items

16. Job close-out report preparation

17. Support Checking of critical lines

18. Support checking of Non-critical line

19. Isometric review and issue

20. Other miscellaneous activities which are not listed above

After listing all such activities one needs to decide on actual time factors for each activity based on experience and then finally combine all those to get the final man-hour.

Excellent site. A lot of useful information here. I鈥檓 sending it to a few friends ans additionally sharing in delicious. And naturally, thank you for your effort!

I think the adminn of this website is actually worrking hard in favor of his site, because here every

material is quality based data.

On Stress Packages how to discriminate the threes highly critical, moderately critical and lower critical. Is there any tabulation for it. Besides, What does it mean of the Package?

Package means to Stress Model or Stress System.

Also highly critical, moderately critical and lower critical line selection criteria you will find in stress design basis of specific project.

Please check method number 2, I think it needs to be revised for the number 4 mentioned in the method.

Very good, could you please send it to my email?

H-H -I do it by isometric.

Thank you Sir. I am an early professional in field of Piping stress Analysis. The way you deliver the knowledge of stress analysis is really very helpful for a Stress Engineer like me who has just entered this world and want to explore it by gaining knowledge. I highly appreciate your efforts.