The full form of PSSR is Pre-Startup Safety Review. It is an important element of the process safety management program. For chemical, petrochemical, oil and gas industries, safety is very important as they handle highly hazardous fluids. Pre-startup safety review or PSSR provides a final check prior to the commissioning of the processing facility to ensure that all the design and construction aspects are in order and it is safe to introduce the hazardous chemical into the system. In this article, we will explore more about PSSR; its purpose, importance, and process.

What is Pre-Startup Safety Review or PSSR?

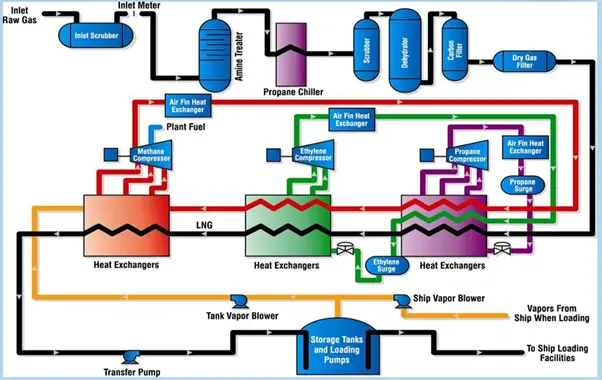

A PSSR or pre-startup safety review is a systematic and thorough check of the plant and process to ensure safety and efficacy before bringing the system into operating mode. All new and modified facilities where any change modifies the process safety information should pass through this crucial process safety management review cycle. Agencies like OSHA (Occupational Safety & Health Administration), EPA (Environmental Protection Agency), etc require that all organizations must conduct PSSR before commissioning the plant to confirm that the plant is ready for start-up.

Pre Startup Safety Review should cover a review of all equipment, operating, maintenance, emergency procedures, and training. PSSR confirms that all appropriate elements of process safety management have been satisfactorily addressed.

In general, the PSSR for any project is usually one. However, some projects may require a number of PSSRs if the different process and utility modules are commissioned at different stages. PSSR is usually associated with the safe handover of the project from construction completion to the plant operation team.

In general, a PSSR must be performed before the startup of all the following circumstances:

- Equipment modification.

- Installation or change of new valves.

- Addition of new control system/modification.

- New feedstock or catalyst.

- A new type of reactor or process vessel.

- Capital projects.

- Startup after an emergency shutdown

- Startup after a turnaround

- Significant operation or process changes.

- Start-up after major maintenance.

Purpose of PSSR

Basically, the primary purpose of PSSRs is to avoid workplace incidents and resultant damage to assets and mankind. The main purposes behind the pre-startup safety review can be listed as follows:

- PSSR ensures that installations conform to the original design and operating intent of the plant.

- It confirms that safety, operating, maintenance, and emergency procedures are taken care of and adequate.

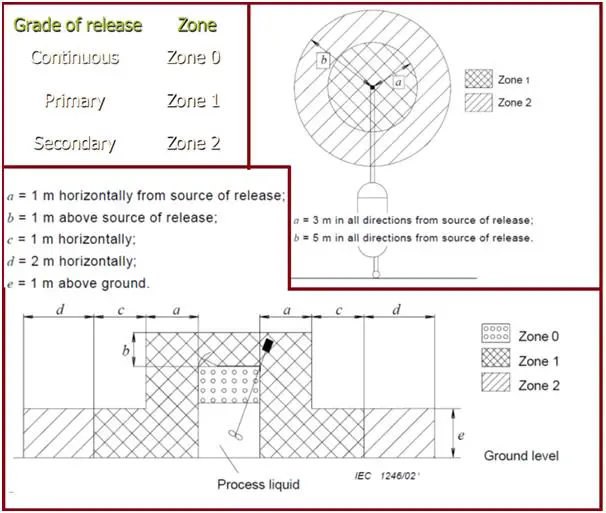

- The pre-startup review ensures that all safety workshops like HAZOP study, model review, HAZID, etc are completed during the detailed engineering phase.

- It also ensures all site modifications during the construction phase are recorded and controlled.

- PSSR emphasizes that employees involved in the operating process are properly trained.

A pre-startup safety review is also sometimes known as a pre-startup safety audit (PSSA) and it gives the plant owners the authority to refuse the plant responsibility when PSSR is not performed.

The Pre-Startup Review Team

The PSSR team will be a multi-disciplinary team consisting of various disciplines. The Head of Operations (or sometimes Lead Project Engineer) is generally the leader of the PSSR team. Depending on the type of project, the following professionals are usually included in the PSSR team:

- A knowledgeable and authoritative supervisor

- Design and construction personnel

- Engineering personnel responsible for the design of the project.

- Instrument and controls personnel

- Maintenance personnel or their representative.

- Operations personnel or their representatives.

- Safety personnel

- Environmental specialist.

- Emergency response department representative.

- Inspection department representative.

- Industrial hygiene representative.

The team should a minimum of three people to a maximum of 10 people. One person from the team can perform multiple roles.

Key Steps involved in a Pre-startup Safety Review

The important steps in a PSSR must be written in a PSSR procedure. Some of the important steps are:

- PSSR team meeting to explain the PSSR purpose and decide on the PSSR checklist. Reviewing P&ID and all other relevant documents.

- Visit the actual site and control room to find out about start-up readiness.

- Review all items physically following the exhaustive checklist and noting down action points if any.

- Working on the action points by the relevant discipline and tracking and once satisfied team sign-off.

- Proper documentation of all the actions performed.

PSSR Checklist

The PSSR checklist is an important document that lists all the required actions to be reviewed while the pre-startup safety review process. The PSSR checklist must include all the key elements that impact any process safety information change. A typical PSSR checklist can be found here.

References and Further Studies

To learn more about the PSSR process and its importance, the following documents can be studied: