What is Space Velocity?

In chemical engineering, space velocity refers to the

Space velocity = flow rate of the feeds/ volume of the reactor (or volume of the catalyst)

Space Velocity signifies how many reactor volumes of feed can be fed in unit time (for instance, a reactor with a space velocity of 1 hr−1 is able to process feed equivalent to one time the reactor volume each hour). It is reciprocal of the reactor space-time.

Mathematically, it is expressed as SV = Vo / V. where Vo is the volumetric flow rate of the reactants, and V represents the volume of the reactor or the volume of the catalyst. This expression is the reciprocal of space-time, τ (i.e. SV = 1/τ).

Types of Space Velocities

There are different types of space velocities which are as follows:

- GHSV, gas hourly space velocity: It is basically the ratio of volumes of gas present in feed gas at STP/hr to the volume of the reactor or catalyst denoted as gas feed @ scfh/ft3.

- LHSV, liquid hourly space velocity: It is the ratio of the Volume of liquid present in feed at 60″F/hr to the volume of reactor or catalyst & denoted as liquid feed@ scfh/ft3.

- WHSV, weight hourly space velocity: It is the ratio of wt of feed/hr to the weight of the catalyst

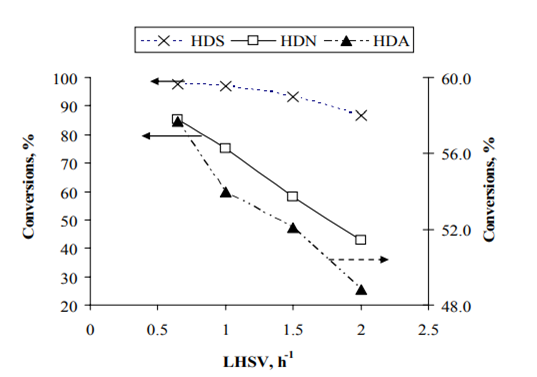

Among these three types of space velocities, LHSV is frequently used in the oil and gas industry. It has significant impacts on hydrotreating reactions mainly in hydro-desulphurization (HDS), hydro-denitrogenation (HDN), and hydro-dearomatization (HDA).

How does LHSV affect hydrotreating reactions?

As the Liquid Hourly Space velocity (LHSV) is the ratio of the volumetric flow rate (hourly) of the liquid feed to the volume of the catalyst present in the reactor. So, LHSV is reciprocal of the space-time. Reducing LHSV generally results in an enhancement of the hydrotreating reaction. However, an excessive reduction of LHSV can create the operation difficult due to the hydraulic perspective & it can cause channeling which leads to liquid mal-distribution and under-utilization of the catalyst. A significantly high LHSV not only reduces the feed & catalyst contact time but also increases the reactor pressure drop and other hydraulic challenges.

How does LHSV affect feed vaporizations?

The higher the LHSV the faster will be the vaporization of feed as well as H2 dissolution. An increase in LHSV implies a hike in the feed flow rate (liquid). According to Raoult’s Law, with the increase of the mole fraction of a component in a solution, the partial pressure also increases, and consequently the escaping tendency increases. Therefore, more liquid feed is introduced into the reactor, and evaporation rates also become faster. Also, by increasing the liquid flow rate, there is more liquid volume for H2 to dissolve in. Hence, increases in H2 dissolution were observed.

How does LHSV affect conversion?

LHSV, which is the reciprocal of space-time, signifies the time spent in the reactor of the reactants. It was observed that reducing LHSV leads to an increase in the conversion in HDS, HDN, and HDA reactions (see the below figure).

The Effects of increasing LHSV & other parameters on hydrotreating activities.

| Variables | Temperature | Pressure | LHSV |

| Ranges | 300-450°C | 4.5-12.5 MPa | 0.5-4 h-1 |

| HDS | Increase | Increase | Decrease |

| HDN | Increase | Increase | Decrease |

| HDA | Increase | Increase | Decrease |

Variation of LHSV & Coke Laydown

The formation of coke is desirable during reaction in the reactor as it reduces catalyst activity tremendously.

As the quantity of catalyst is constant, the only way to vary LHSV is by varying the feed flow rate. A change in feed capacity will change the space velocity & the reactor inlet temperature must be changed to maintain the same severity.

To avoid coke formation the following rules shall be applied:

- Decrease reactor inlet temperature before lowering the feed flow rate.

- Increase the feed flow rate before increasing the reactor temperatures.

Calculation of Space velocity

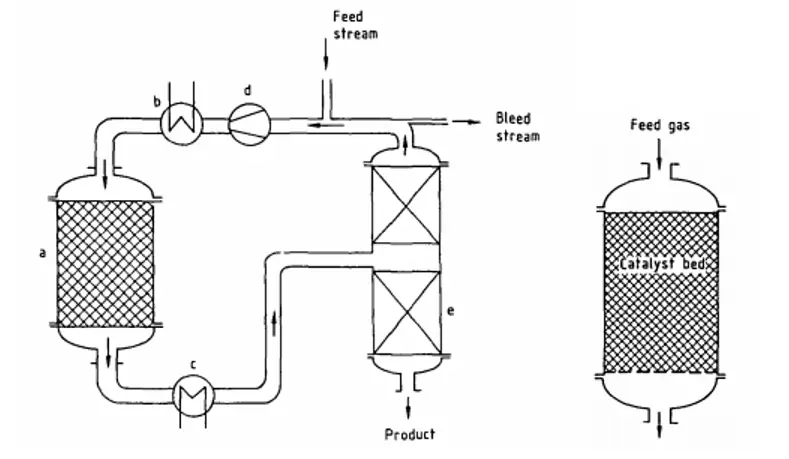

Space velocity especially for hydrocracking & hydrotreating reaction is calculated by conversion of BPSD (rated) into equivalent cubic feet at 60oF i,e (BPSD x 5.615)/24, for a day. The total catalyst volume is to be determined in ft3 by taking the cross-sectional area of the reactor x sum of the vertical heights of a bed of the catalyst excluding the top disc & alumina supported balls.

Another way of calculation is, first convert BPSD to mt/hr, i,e BPSD/(6.29 x S.G of oil @ 60’F) divided by 24 hrs. The volume of (ft3) of active catalyst is converted to weight through the multiplication of the bulk density of the catalyst. Normally loaded density depends on sock loading or dense loading & this density falls between 45 lbs/ft3 sock loading to 50 lbs/ft3 dense loading.

What is space-time in a reactor?

The Space-time of a reactor is defined as the time required to process one reactor volume of feed into a reactor at the inlet condition. It is basically denoted as τ (tau) = V/Vo where V is the reactor volume & Vo is the volumetric flow rate of feed.

Residence time & Space-time

Both times are similar but not exactly the same. Space time is the time needed to process a reactor volume of feed at the reactor inlet condition and the residence time is the average time spent by a reactant particle until it exits from the reactor.

Hello,

How do I calculate WHSV for a batch reactor?

My feed is 35 gm, the catalyst is 0.5 gm, time is 300 mins or 5h and reactor volume is 100 ml.

Please help,

Thank you.

35 gm of feed is flowing in 5 h time which means the mass flow rate of feed is 35/5=7 gm/h.

Catalyst mass is 0.5 gm.

Therefore,

WHSV=mass flow of feed/ mass of catalyst = 7/0.5 =14 per hour