The storage tank is a very important static equipment for the oil and gas industry to store fluids. Even though various codes and standards stipulate its design to avoid failure of storage tanks, still there are many incidents of storage tank failures. So, storage tank failure is not at all a new phenomenon. In this article, we will explore the causes of such tank failures and steps for prevention.

Types of Storage Tanks (API 650)

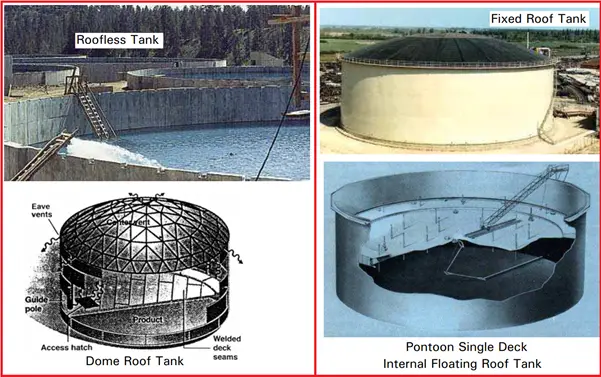

Storage Tanks can be classified on many bases based on service, based on construction, based on Pressure & Temp & based on the roof (Atmospheric Pressure). Here, We will list the storage tank types based on the roof construction.

- Double-Deck Floating Roof Tanks (DDFR): Double-deck floating roof Tank has two layers of the deck that floats over the product inside the Tank. This type of Tank construction consumes too much material as the deck is double. But it is used only for highly volatile products.

- Single Deck Floating Roof (SDFR): Single deck floating roof Tanks are similar to DDFR; the only difference is the deck that floats is single. It uses bouncy for this type of Tank to maintain floatation.

- Cone Roof (CR): Cone roof Tanks have a Cone roof. The roof slope is subject to the designer but 1:100 is common practice.

- Internal Floating Roof (IFR): Internal floating roof Tanks are basically a collaboration of deck and roof. So, these types of tanks will have a Deck as well as a roof. The type of deck can be any type it may be single deck or Double deck Pan type.

- Dome Roof (DR):– Dome roof Tanks are almost the same as the Cone roof; the only difference is they would not carry any deck and the shape of the roof will be Dome type.

- Click here to know more about various types of atmospheric storage tanks

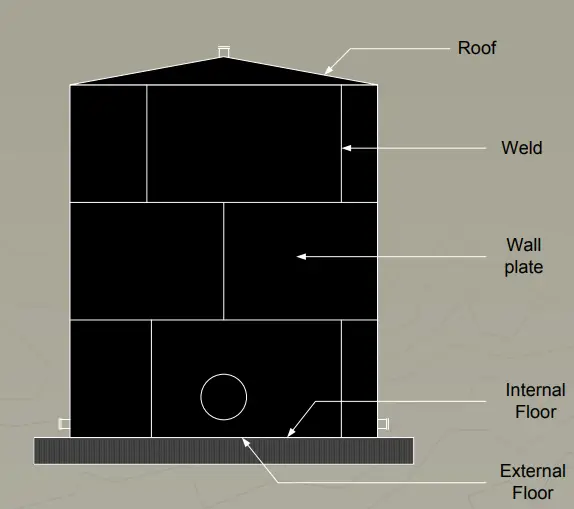

Detailed indication and nomenclature of roof-type storage tanks could be seen in Fig 1. Normally storage tanks fail in any one of the locations mentioned in Fig. 1.

Common Causes of Storage Tank Failures

Various studies conclude that majority of the storage tank failures are due to any one or combination of the following causes:

- Corrosion: Most Common cause of storage tank failures

- Improper Construction

- Poor Maintenance

- Incompatibility of fluid with the tank wall

- Dispensing problems

- Lack of Physical Safety i.e, Internal/External forces or events (Flood, fire, impact, etc.)

- Excessive Pressure due to overfilling of Storage Tanks

- Age/UV-related issues with non-metallic tanks

- Failure of Pressure Vacuum Relief Valve (PVRV)

- Seismic design failure

- Scada failure

- overturning because of Wind girder

- Sabotage

- Operational Errors on human interference

- Violent weather changes

Types of Storage Tank failures

Storage tank failure modes can again be divided into various types such as

- failures based on Pumping,

- based on Material,

- based on service,

- Mechanical, civil, or electric failure, etc.

You will get many references for storage tank failures over the net caused by corrosion, improper construction, poor maintenance, etc. We will explain a few storage tank failure examples based on Mechanical Failure.

Storage Tank failure due to Overfilling

In the Guru Gobind Singh Refinery, India (2012), the refinery was handed over for commissioning after the completion of all necessary details. Because of the inadequate time frames and some construction requirements, water was filled into a big tank so that water could be used for hydro testing of other Tanks. It was evening time and the operational people had to go for a shift change. But without informing the other relevant people on the next shift, the responsible person took the bus. So naturally, the valve is not closed. The Tank is filled totally and started overflowing but the overflow rate was not able to control the Pump flow rate. Within a short time span the tank failed, the rafter damaged the roof, the Deck stuck on the top & Weld of the plates of the lower thickness of the upper side gets sheared.

Storage Tank Failure due to failure of the PVRV breaker

In the Sulfur Recovery Unit of the same refinery, one tankage failure incident occurred during commissioning. This failure occurred because of PVRV failure. The operator opens the valve to pump out but because of the PVRV failure, the Tank gets collapsed. Within seconds the tank explodes like a bomb. The products were water and so spreading around didn’t affect them much.

Root cause analysis shows that the PVRV installation had not been cross-checked. Because as per API 650, it’s not necessary to install a pressurized part during Hydro Testing because it’s just like the Water fill test in ATM pressure Tanks.

The following Fig. 3 explains the stage-wise incident of the storage tank failure.

Reason for Failures-

The most common reason for storage tank failure is the lack of knowledge, training, and inspection. In both of the above-mentioned failures, it was found that in both cases operator was not well-trained. The first failure is solely the mistake of the operator. In the second one, it was a PVRV failure but if we check the PVRV before every operation it can save the equipment and human lives. The second failure was in small diameter tanks (9 m diameter) as we can see in Fig 3. it was 9 m dia tanks. We could easily imagine the fatality if the tank diameter was larger.

The root cause analysis is performed to find out the root reason for what happened. After that, the finding is documented in the Lessons learned register for future reference to eliminate the reason for failure in future projects. In this article, we can understand the root was a lack of training & PVRV (supporting) equipment failure.

To make the lesson learned register, help from SME (subject matter expert) can be taken. They will guide and help to document the basic reasons for failure.

Prevention of Storage Tank failures

Failure of Storage Tank systems can be reduced by the following methods.

- All necessary mounting shall be TPI (Third Party Inspection) inspected. Even after FAT (Factory acceptance test) they should be checked at the construction site by the Engineer in charge or in the presence of the Engineer in charge.

- PVRV (Pressure vacuum relief valve) is something that is commonly used. It should be frequently checked during the operation.

- All Tankages shall be protected by the emergency vent system.

- All Tankages shall be inspected periodically.

- The design of the Firewall and bund wall should be considered for contingency reserves.

- External roof supports/self-supporting roofs

- The design of tank thickness has to be proper

- Proper Metallurgy of the used compatible material to reduce corrosion

Code and Standards for Tank inspection to reduce storage tank failures

The following codes and standards provide guidelines for inspection to reduce the failure probability

- API 575 – Inspection of Atmospheric and Low-Pressure Tanks

- API 653 – Tank inspection, repair, alterations, and reconstruction

- API 570 – Piping Inspection Code

- UL 142 – SteelAboveground Tanks for Flammable and Combustible Liquids

- STI SP001 – Standard for Inspection of Above-ground Storage Tanks

Sir, very useful notes for person who interested Storage tank construction job.thanks a lot , I appreciate and again thanks.

Many thanks for sharing interesting information on your blog

This book send me.

Just want to ask. With regards to the tank failure due overfilling. The tank does not have a Float Valve for automatic shutdown to Pump?

Recently we faced a trouble as our internal floating roof was damaged at different points. We have stored Rubber Solvent ,We want to know the cause of failure why did it happen.

Will the bolted tank without gasket ubdergoes displacement and leakages?

Great Job Mr. Dev

Please when was this article on storage tank failure published.

Nicely written about storage tank and it’s safety features. Enjoyed reading,

good article