Tall pipe risers are used in skyscrapers, mines, etc. There are two points that the piping stress engineer should consider:

- Fluid weight load distribution

- Pipe longitudinal stability

Fluid weight load distribution

The most of widely used piping stress analysis software, including START-PROF, applies fluid weight as a uniform load along the pipe. This approach is correct for horizontal piping and short vertical pipes. But it is incorrect for tall risers and may lead to incorrect support loads and incorrect stress distribution along the vertical pipe length.

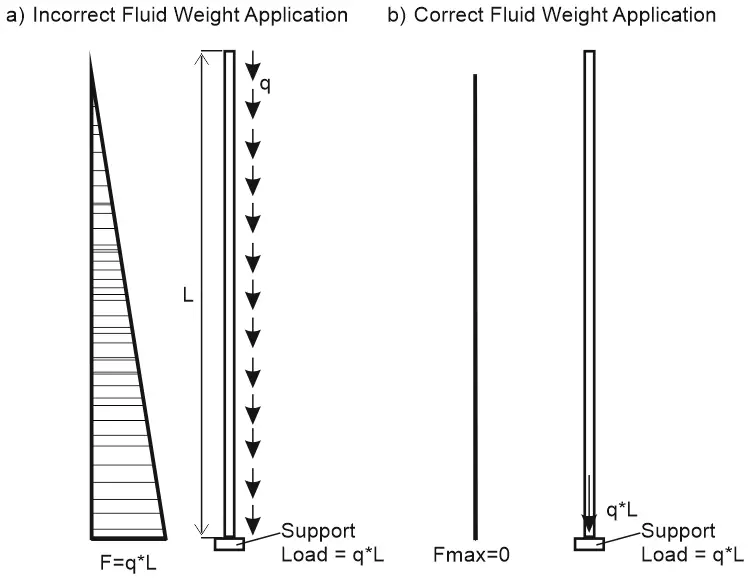

The picture below (a) shows the axial force F diagram caused by uniform load q at the vertical pipe that is supported at the bottom. If fluid weight is applied as uniform load q, the axial force diagram is incorrect. The software will show great axial stresses from sustained loads q*L/A, A – pipe cross-section area. But in real-world fluid pressure will act only on the bottom of the pipe and axial stresses along the pipe should be zero. The correct results can be obtained by applying of concentrated force at the bottom of the pipe instead of a uniform load.

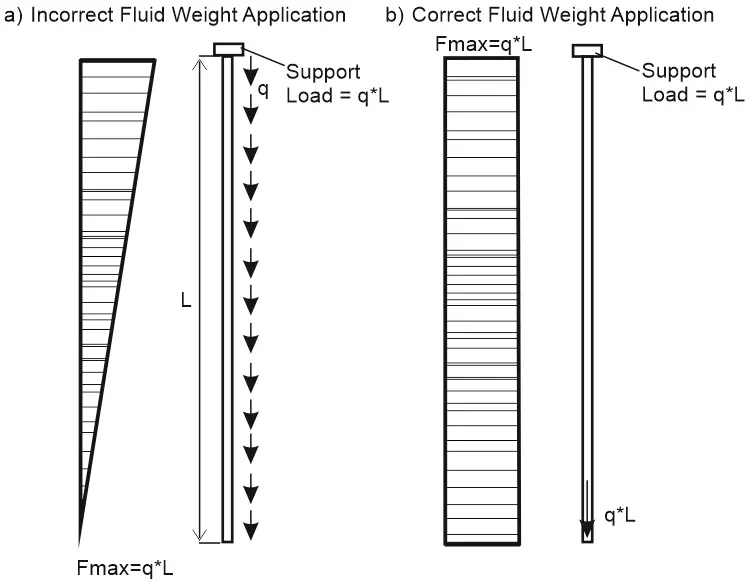

In the case of pipe supporting at the top, uniform load gives incorrect results too. Application of fluid weight as uniform load leads to underestimation of axial stresses at the lower part of the pipe.

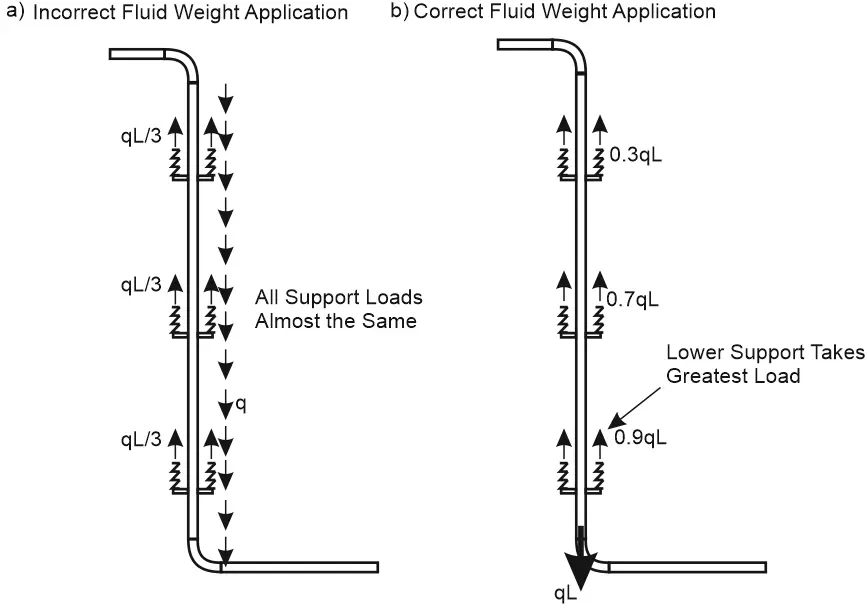

In the case of supporting the riser with several springs, the application of fluid weight as a uniform load will lead to uniform load distribution between supports. But in real-world fluid weight will act in the bottom bend and the lowest support will hold the greatest weight load.

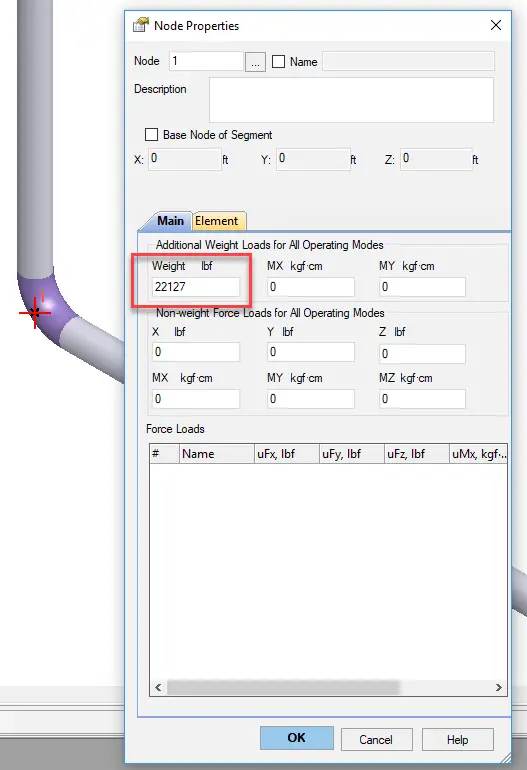

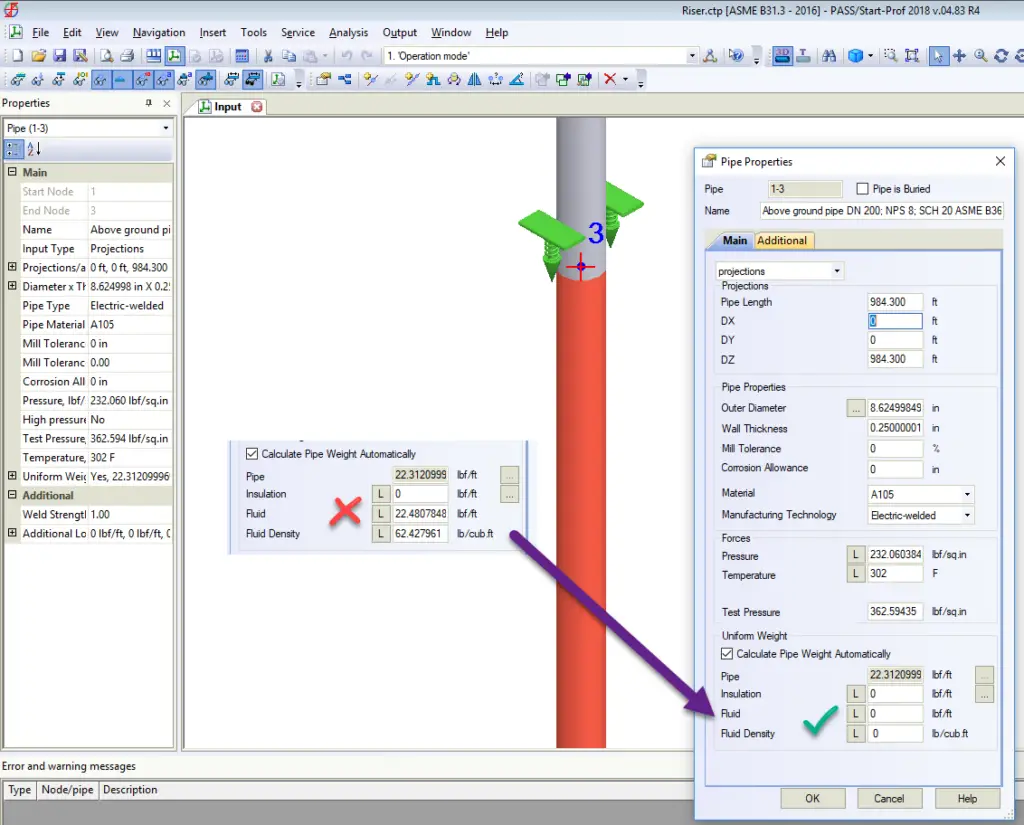

Now let’s see how to model the vertical riser correctly in PASS/START-PROF piping stress analysis software:

- Fluid density should be zero

- Add concentrated force q*L in the lower bend

Pipe Longitudinal Stability

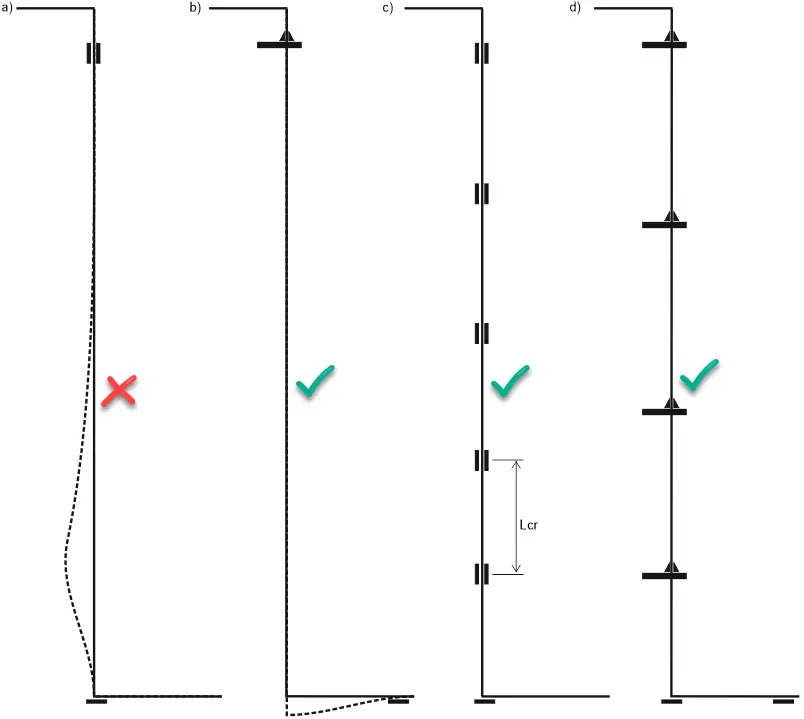

The second problem concerns vertical risers that are supported at the bottom. The pipe is compressed by a big pipe and insulation weight. Compression force may lead to pipe buckling as shown in the drawing (a) below.

To avoid buckling we should add additional V-stop supports (d) to decrease the compressive force or add guides (c) to prevent buckling.

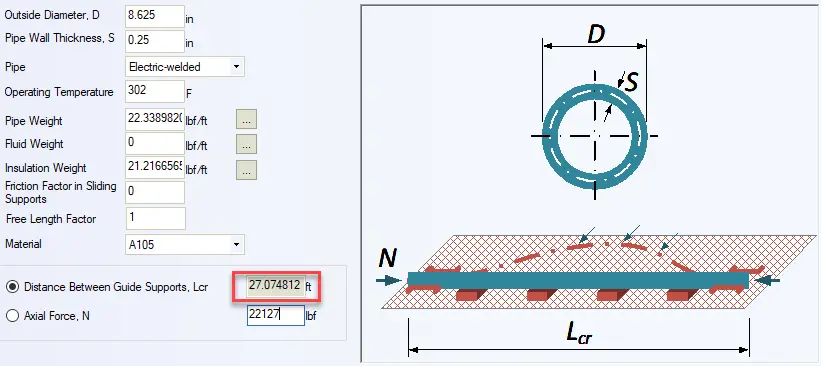

The START-Elements has a special procedure that allows checking to buckle of vertical or horizontal pipe. For vertical pipe, we should set the sliding support friction factor to zero and enter the compressive load N value. The software will calculate the span between guides Lcr needed to prevent buckling.