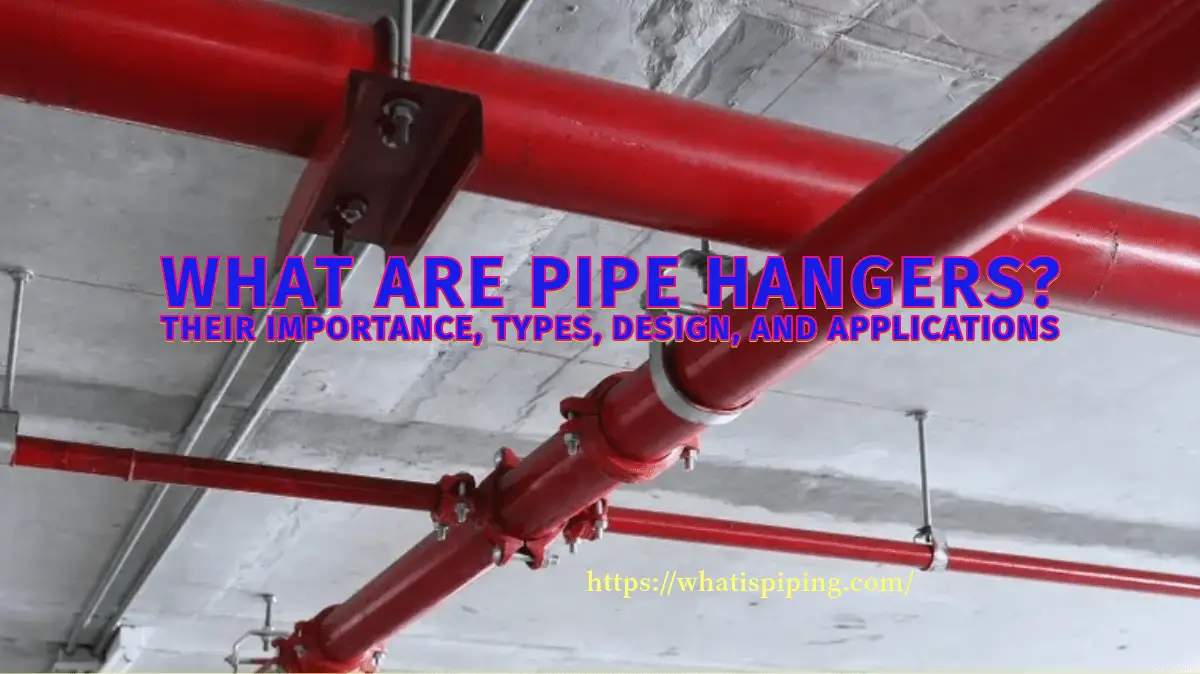

Pipe support brackets play a crucial role in various industries and infrastructure projects. These brackets, also known as pipe hangers or pipe clamps, are essential components for supporting and securing pipes in a wide range of applications. From residential plumbing systems to large-scale industrial projects, understanding pipe support brackets is vital for ensuring the safety, stability, and longevity of the piping infrastructure. This article aims to provide a comprehensive overview of pipe support brackets, including their types, installation, and importance.

What is a Bracket in Piping?

In piping, a bracket, also known as a pipe support bracket is a mechanical device used to support, secure, and position pipes in a piping system. These brackets are essential components that play a crucial role in maintaining the integrity and stability of the entire piping infrastructure. Brackets are designed to hold pipes in place, prevent excessive movement, and distribute the weight of the pipes and their contents to the surrounding structure.

The primary purpose of using brackets in piping is to ensure that the pipes remain in their designated positions and maintain proper alignment, even under various operating conditions. Piping systems can be subject to thermal expansion and contraction, varying fluid pressures, and dynamic forces, which could lead to stress on the pipes. Brackets help mitigate these stresses and maintain the overall functionality and safety of the system.

They can be installed as loose pipe brackets or fixed pipe brackets. A loose pipe bracket allows axial

movement of the pipe. The axial thermal movement is allowed during operational changes when loose pipe brackets are used. The inner diameter of the loose pipe bracket should be larger than the outside diameter of the pipe to allow free pipe movement. Care must be taken to keep the inner edges of the brackets free from any sharp contours to prevent any damage.

On the other hand, a fixed pipe bracket installation prevents the pipe from moving in any direction. The purpose is to control system stresses caused by thermal changes.

Types of Pipe Support Brackets

There are several types of pipe support brackets available, each designed to meet specific requirements based on the pipe’s material, size, weight, and environmental conditions. Here are some common types of pipe support brackets:

- Clevis Hangers: Clevis hangers are U-shaped brackets that cradle the pipe from beneath, providing support and flexibility to accommodate pipe movement due to thermal expansion and contraction. They are ideal for suspending vertical pipes.

- Pipe Clamp Brackets: Pipe clamp brackets are widely used for securing pipes to various surfaces, such as walls, beams, or ceilings. They consist of a clamp that encircles the pipe and is fixed to a mounting structure.

- Roller Hangers: Roller hangers allow for the horizontal movement of pipes and are often used in applications where thermal expansion and contraction are significant factors. The rollers enable smooth pipe movement, reducing stress on the pipe and support system.

- Split Rings: Split rings are simple, cost-effective pipe support brackets that resemble a closed loop. They are used in both vertical and horizontal pipe installations and are commonly employed in residential plumbing systems.

- Riser Clamps: Riser clamps are designed to support vertical pipes, such as those found in high-rise buildings. They provide reliable support and prevent excessive movement in taller pipes.

- Swivel Rings: Swivel rings are versatile brackets that allow for angular adjustment of the pipe. They are useful when alignment adjustments are necessary during installation.

Installation of Pipe Support Brackets

Proper installation of pipe support brackets is critical for ensuring the integrity and functionality of the piping system. Here are some essential steps to follow during the installation process:

- Engineering and Design: Before installation, it is essential to have a detailed engineering plan that considers the weight, material, and size of the pipes, as well as the environmental conditions and potential thermal expansion.

- Selecting the Right Bracket: Choose the appropriate pipe support bracket based on the type of pipe and its intended function. Consider factors such as the pipe’s load-bearing capacity, thermal expansion allowance, and attachment surface.

- Positioning and Spacing: Position the brackets at appropriate intervals to adequately support the weight of the pipes. The spacing will depend on the pipe material, size, and expected loads.

- Attachment to Structure: Ensure that the brackets are securely attached to the building or supporting structure using suitable fasteners. Properly secured brackets prevent pipe sagging or detachment.

- Insulation Considerations: If the pipes are intended to transport hot or cold substances, consider adding insulation to prevent thermal energy loss and potential damage to nearby structures.

Importance of Pipe Support Brackets

Pipe support brackets are indispensable for various reasons, including:

- Safety and Stability: Properly installed brackets prevent pipes from sagging or falling, minimizing the risk of accidents and structural damage.

- Prolonged Pipe Life: By supporting pipes adequately, brackets help distribute the weight and reduce stress, extending the lifespan of the pipes.

- Reducing Noise and Vibration: Brackets can dampen vibrations and reduce noise caused by the flow of fluids through the pipes, improving the overall comfort of the environment.

- Thermal Expansion Control: Pipe support brackets accommodate thermal expansion and contraction, preventing damage caused by excessive stress on the pipes.

- Compliance with Regulations: Using appropriate pipe support brackets ensures compliance with building codes and industry standards.

Materials for Pipe Support Brackets

Pipe support brackets can be made from a variety of materials, each offering specific characteristics that make them suitable for different applications. The choice of material for pipe support brackets depends on factors such as the type of piping system, the environment in which the brackets will be used, the load-bearing requirements, and budget constraints. Some common materials used for pipe support brackets include:

- Steel: Steel is one of the most widely used materials for pipe support brackets due to its excellent strength, durability, and cost-effectiveness. Carbon steel is commonly used for standard applications, while stainless steel is preferred for environments where corrosion resistance is critical, such as in marine or chemical processing industries.

- Aluminum: Aluminum brackets are lightweight, making them ideal for applications where weight reduction is a concern. They are often used in industries such as aerospace or where corrosion resistance is required, such as in outdoor installations.

- Cast Iron: Cast iron brackets are known for their robustness and ability to handle heavy loads. They are commonly used in industrial applications, especially when dealing with large-diameter pipes or high-temperature systems.

- PVC (Polyvinyl Chloride): PVC brackets are used in applications where chemical resistance and non-conductivity are essential. They are commonly employed in the chemical industry and water treatment facilities.

- Polypropylene (PP) or Polyethylene (PE): These materials offer excellent chemical resistance and are commonly used for supporting pipes in aggressive chemical environments.

- Fiberglass Reinforced Plastic (FRP): FRP brackets are corrosion-resistant, making them suitable for marine and chemical processing industries. They are also lightweight and have high strength-to-weight ratios.

- Galvanized Steel: Galvanized steel brackets are coated with a layer of zinc to provide corrosion resistance. They are commonly used in outdoor or exposed environments where rust and corrosion could be an issue.

- Thermoplastic Coated Steel: These brackets are steel brackets coated with a layer of thermoplastic material, offering enhanced chemical resistance and protection against corrosion.

- Copper: Copper brackets are used in specific applications where thermal conductivity is required, such as in HVAC systems.

- Polyamide (Nylon): Nylon brackets offer good chemical resistance and are often used in applications where metal brackets could cause damage to pipes due to contact.

It is essential to consider factors like the material’s strength, chemical resistance, thermal properties, and compatibility with the pipe material when choosing the appropriate pipe support bracket material. Proper material selection ensures the longevity and reliability of the pipe support system in its intended application.

Selection of Pipe Brackets

Selecting the right pipe support brackets is crucial to ensure the safety, stability, and longevity of the piping system. Several factors need to be considered when choosing pipe brackets, including the type of pipe, pipe material, pipe size, operating conditions, load requirements, and the environment in which the brackets will be used. Here are some steps to guide you through the selection process:

- Pipe Type and Material: Identify the type of pipe in the system (e.g., metal, plastic, copper) and its material (e.g., carbon steel, stainless steel, PVC). Different pipe materials have varying weights, thermal expansion rates, and chemical compatibility, which will influence the choice of brackets.

- Pipe Size and Weight: Determine the outer diameter and wall thickness of the pipe to calculate its weight per unit length. Select pipe support brackets that can accommodate the pipe’s size and weight while providing sufficient load-bearing capacity.

- Operating Conditions: Consider the operating temperature and pressure of the piping system. Some brackets may not be suitable for high-temperature or high-pressure applications, and special materials may be required for extreme conditions.

- Thermal Expansion and Contraction: Account for thermal expansion and contraction of the pipes due to temperature changes. Choose brackets that allow for some movement to accommodate these fluctuations without causing stress on the pipe.

- Environmental Factors: Consider the environment in which the brackets will be installed. Factors such as humidity, exposure to corrosive substances, UV radiation, or outdoor weather conditions may influence the material choice. Stainless steel or corrosion-resistant coatings may be required for harsh environments.

- Load-Bearing Capacity: Ensure that the selected brackets can handle the weight of the pipes, along with the contents they carry. Factor in any potential additional loads, such as insulation or fluid contents, when calculating the total load.

- Vibration and Noise Dampening: For applications where vibration and noise are a concern, opt for brackets that have vibration-damping properties to reduce noise and prevent resonance.

- Type of Brackets: Choose the appropriate type of bracket based on the pipe’s orientation (horizontal, vertical), installation method (wall mount, ceiling mount, floor mount), and adjustability requirements (if needed).

- Compliance with Codes and Standards: Ensure that the selected brackets comply with relevant building codes, industry standards, and safety regulations to maintain the integrity of the piping system.

- Budget Considerations: Evaluate the cost of the brackets and find a balance between quality, functionality, and budget constraints.

Horizontal Pipe Support Brackets vs Vertical Pipe Support Brackets

Horizontal pipe support brackets are mechanical devices used to provide support and stability to pipes that run parallel to the ground or in a horizontal orientation. These brackets are attached to the structure’s vertical surfaces, such as walls, beams, or columns, and they cradle the pipe from below. Horizontal pipe support brackets are essential for preventing sagging and ensuring the pipe’s proper alignment, especially in cases where pipes are carrying liquids or other materials that could exert significant weight. These brackets may come in various types, such as clevis hangers or pipe clamp brackets, to accommodate different pipe sizes and loads.

Vertical pipe support brackets, also known as riser clamps, are designed to support and secure vertical pipes, such as those found in high-rise buildings or installations where pipes need to be held vertically. They are typically attached to the building’s structural elements, ensuring that the pipes remain stable and do not experience excessive movement or bending. Vertical pipe support brackets are crucial for maintaining the integrity of tall pipe runs and preventing potential damage due to gravitational forces and other dynamic loads.

Adjustable Pipe Support Brackets

Adjustable pipe support brackets are brackets that offer the flexibility to modify their length or position, allowing for precise adjustments during installation or maintenance. These brackets are beneficial when the exact positioning of the pipe may need fine-tuning, such as aligning multiple pipes or accommodating slight variations in pipe lengths. Swivel rings and certain types of roller hangers are examples of adjustable pipe support brackets. They allow for angular adjustments and movement, ensuring proper alignment and reducing stress on the pipes.

Wall Mount Pipe Brackets

Wall mount pipe brackets, as the name suggests, are brackets specifically designed to attach pipes to vertical surfaces such as walls. They are commonly used in applications where pipes need to be run along the walls, either to save space or to maintain a certain aesthetic appearance. Wall mount brackets come in various styles, including pipe clamp brackets, split rings, and clevis hangers, depending on the specific requirements of the piping system. These brackets securely hold the pipe in place, prevent sagging, and ensure the pipes remain safely affixed to the wall. They are also known as pipe wall brackets. Fig. 1 below shows various types of pipe support brackets.

Conclusion

Pipe support brackets are integral components of any piping infrastructure, providing stability, safety, and longevity to the system. By understanding the various types of brackets available, following proper installation procedures, and recognizing their importance, engineers, contractors, and maintenance personnel can ensure the seamless functioning of pipe systems across residential, commercial, and industrial applications. Properly supported pipes lead to more reliable and efficient operations, safeguarding the infrastructure for years to come.

Online Course on Pipe Support Engineering

If you want to learn more details about pipe support engineering then the following online course is a must for you: