A clevis hanger is a type of mechanical support device widely used in the piping and plumbing industries. This pipe attachment is specifically designed to support and suspend piping systems, such as pipes, tubes, and conduits, from overhead structures or beams. Clevis hanger provides vertical adjustments and is quite flexible for supporting pipes. They are in general preferred for non-insulated piping systems. However, clevis hangers can be used for insulated piping systems, as well.

Components of a Clevis Hanger

The clevis hanger consists of two main components: a U-shaped clevis and a threaded rod. The clevis is a metal bracket or yoke with two holes that are used to attach the hanger to the supporting structure. One hole is for connecting the hanger to the threaded rod, while the other hole is used to fasten the hanger to the structure using bolts or other suitable means.

The threaded rod, often referred to as a hanger rod or hanger bolt, extends vertically downwards from the clevis. It provides the means to adjust the height of the suspended piping system by turning the rod clockwise or counterclockwise.

Applications of Clevis Hangers

Clevis hangers are commonly used in applications where there is a need to support pipes, ducts, or conduits while allowing for some degree of movement or adjustment. They are often used in HVAC (Heating, Ventilation, and Air Conditioning) systems, plumbing installations, fire sprinkler systems, and industrial piping systems. Clevis hangers are commonly used for the following systems:

- HVAC (Heating, Ventilation, and Air Conditioning): Clevis hangers are extensively used in HVAC systems to support ductwork, air handling units, and ventilation pipes.

- Plumbing Systems: Clevis hangers provide support for pipes and conduits in plumbing installations, including water supply lines, drainage systems, and sewage pipes.

- Fire Sprinkler Systems: Clevis hangers are used to suspend fire sprinkler pipes and ensure proper alignment and support for the sprinkler system.

- Industrial Piping: Clevis hangers are employed in industrial settings to support various types of pipes, including process piping, chemical lines, steam lines, and hydraulic systems.

- Commercial Buildings: Clevis hangers are utilized in commercial structures such as office buildings, hospitals, schools, and shopping centers to support plumbing and HVAC systems.

- Power Plants: Clevis hangers are used in power generation facilities to support piping systems for steam, water, fuel, and other fluids.

- Oil and Gas Industry: Clevis hangers find applications in the oil and gas sector for supporting pipelines, including offshore platforms, refineries, and pipelines.

- Petrochemical Plants: Clevis hangers are used in petrochemical facilities to support various piping systems involved in the transportation and processing of chemicals.

- Water Treatment Plants: Clevis hangers provide support for pipes used in water treatment facilities, including filtration systems, pump stations, and distribution networks.

- Industrial Process Systems: Clevis hangers are employed in a wide range of industrial processes, including food processing, pharmaceutical manufacturing, chemical production, and pulp and paper mills.

The design of clevis hangers allows for easy installation and adjustment, making them versatile and convenient for various pipe support requirements. They provide stability and help distribute the weight of the suspended pipes or conduits evenly, reducing stress and potential damage to the piping system and the supporting structure.

Materials for Clevis Hangers

Clevis hangers are typically made from various durable and corrosion-resistant materials to ensure their strength and longevity. The choice of material depends on the specific application and environmental factors. Here are some common materials used in the design of clevis hangers:

- Carbon Steel: Carbon Steel is a popular choice due to its high strength and durability. However, carbon steel is prone to corrosion and hence suitable measures must be exercised to reduce corrosion.

- Stainless Steel: Stainless steel provides high corrosion resistance along with the required strength. But, stainless steel is costly as compared to carbon steel.

- Galvanized Carbon Steel: Galvanized carbon steel is a good choice which helps in protecting corrosion as well.

- Cast Iron: Cast iron clevis hangers are known for their exceptional strength and load-bearing capacity. They are often used in heavy-duty applications.

- Malleable Iron: Malleable iron combines the strength of cast iron with improved malleability and ductility, making it easier to shape and manipulate during manufacturing.

- Aluminum: Aluminum clevis hangers offer lightweight properties, making them suitable for applications where weight reduction is desired. They also exhibit good corrosion resistance.

- Galvanized Steel: Galvanized steel clevis hangers are coated with a layer of zinc, providing enhanced corrosion resistance. They are commonly used in outdoor or high-moisture environments.

- PVC (Polyvinyl Chloride): PVC clevis hangers are used for supporting plastic piping systems. They are lightweight, non-corrosive, and resistant to chemicals, making them suitable for certain applications.

Clevis Hanger Sizes

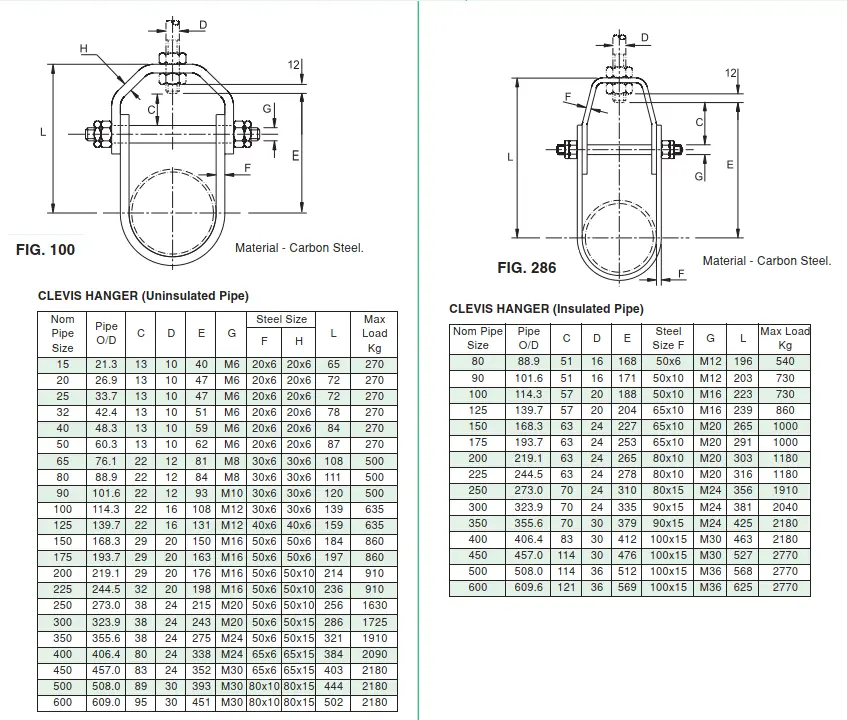

In general, clevis hangers are manufactured to support pipes from 1/2 inch through 24 inches. However, custom-designed clevis hanger sizes can be produced when required. The dimensions of each component may vary from one manufacturer to another. Accordingly, the load-carrying capability of the clevis hanger also varies. The following image from Carpenter and Paterson catalog is reproduced below to provide a reference about how much weight a clevis hanger can carry.

Clevis Hanger Specification

The following information needs to be mentioned to specify a clevis hanger for ordering.

- Material of Construction

- Figure Number as per the specific manufacturer (For example, Fig. 100 as per C&P catalog)

- Nominal pipe size

Clevis Hanger Manufacturers

Some of the well-established and popular manufacturers of clevis hanger support are listed below:

- Anvil International

- Piping Technology and Products

- Carpenter & Paterson

- Taylor Pipe Supports

- Globe Pipe Hanger Products

- Oatey

- Hilti

- Buckaroos, Inc.

- ERICO (nVent)

- Empire Industries

- Fischer International

Difference between Clevis Hanger and Pipe Clamp

While both clevis hangers and pipe clamps serve the purpose of supporting and suspending piping systems, there are notable differences between the two in terms of their design, functionality, and applications. Here are some key distinctions:

| Clevis Hanger | Pipe Clamp |

| A clevis hanger consists of a U-shaped clevis and a threaded rod. The clevis has two holes, one for attaching the hanger to the supporting structure and the other for connecting the hanger to the threaded rod | A pipe clamp typically consists of a metal band or strap that wraps around the pipe and is secured using bolts or other fasteners. It may also have a cushioning material or lining to protect the pipe surface |

| Clevis hangers are typically attached to the supporting structure using bolts or other suitable means. They provide vertical support and allow for adjustment of the suspended pipe’s height | Pipe clamps directly wrap around the pipe and are fastened using bolts or other fasteners. They provide lateral support and are used to secure pipes to walls, beams, or other structural elements. |

| Clevis hangers primarily provide vertical support and suspension for pipes. They allow for some degree of movement and adjustment to accommodate thermal expansion, contraction, or system adjustments. | Pipe clamps are designed to secure pipes in place, preventing movement or vibration. They provide lateral support and help distribute the load along the pipe’s length. |