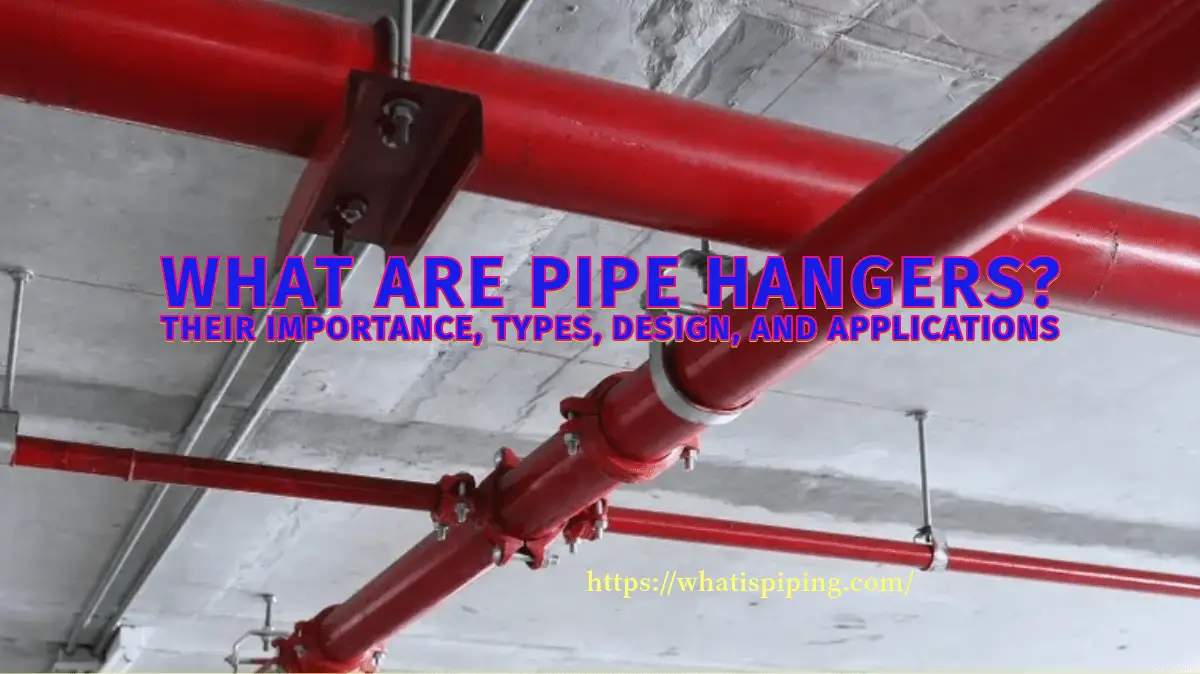

Trapeze hangers are support structures designed to suspend multiple pipes from overhead structures, such as ceilings or beams. They consist of horizontal supports (often a metal bar or channel) from which pipes are hung using brackets or clamps. When it comes to supporting pipes in various industrial and commercial settings, trapeze hangers have emerged as a popular and effective solution. These versatile supports offer numerous benefits over traditional methods, making them a go-to choice for engineers, architects, and construction professionals. In this article, we’ll learn about trapeze hangers and explore the advantages they bring to the table.

What is a Trapeze Hanger?

A trapeze hanger is a type of pipe support system used in various industrial, commercial, and construction applications. It is designed to suspend pipes or ducts from a ceiling, overhead structure, or framework, keeping them securely in place while allowing for adjustments if necessary. This is basically a strut-based pipe-hanging support solution.

The use of trapeze hangers dates back to the early days of plumbing and HVAC systems. As industrialization progressed, the need for effective pipe support systems became critical, leading to the development of specialized hanging methods.

The name “trapeze hanger” comes from its distinctive shape, resembling the form of a trapeze used in gymnastics. The hanger consists of a horizontal bar (usually made of steel) that is supported by vertical rods or wires at each end. The suspended pipes are then attached to the horizontal bar, which evenly distributes the load along its length. Fig. 1 (Image Credit: https://www.walraven.com/) below shows a typical trapeze hanger assembly supporting pipes.

Components of a Trapeze Hanger Pipe Support

A trapeze hanger assembly typically consists of several key components that work together to support and suspend pipes or ducts from a ceiling or overhead structure. These components can vary depending on the specific design and manufacturer, but the following are common elements found in most trapeze hanger systems:

- Horizontal Bar (Trapeze Bar): The horizontal bar is the main component of the trapeze hanger and gives it its characteristic shape. It is usually made of steel and serves as the primary support for the suspended pipes or ducts. The horizontal bar is where the pipes or ducts are attached using various accessories.

- Vertical Support Rods/Wires: These are the vertical components that connect the horizontal bar to the ceiling or overhead structure. They provide the necessary stability and load-bearing capacity to hold the entire trapeze hanger system in place. The number of vertical supports used may vary based on the length of the horizontal bar and the weight of the pipes being supported.

- Threaded Rods or Bolts: Threaded rods or bolts are used to connect the horizontal bar to the vertical support rods or wires. They allow for adjustments in height and facilitate the proper alignment of the trapeze hanger system.

- Clamps or Attachments: Clamps or attachments are used to secure the pipes or ducts to the horizontal bar. These may include U-bolts, channel clamps, beam clamps, or other specialized fasteners that provide a secure connection while accommodating different pipe sizes and configurations.

- Locknuts and Washers: These components are used in conjunction with threaded rods to secure the attachments to the horizontal bar. Locknuts prevent loosening due to vibrations, while washers help distribute the load and protect the surface of the horizontal bar.

- Hanging Hardware: In some cases, additional hanging hardware such as hooks or clips may be used to suspend the trapeze hanger system from the ceiling or overhead structure. These provide a reliable connection point for the vertical support rods or wires.

- Corrosion Protection: Depending on the application and environment, trapeze hangers may be constructed from materials with corrosion-resistant properties. This helps to ensure the long-term durability and integrity of the hanger system, especially in harsh or corrosive environments.

- Optional Accessories: Some trapeze hanger systems may include optional accessories like pipe insulation clamps, roller hangers, or sway braces to further enhance the functionality and support of the overall piping infrastructure.

Types of Trapeze Hangers

Trapeze hangers come in various types, each suited for different applications. Understanding the types can help in selecting the right hanger for a specific project.

Standard Trapeze Hangers

Standard trapeze hangers consist of two vertical supports and a horizontal beam. These are typically made from steel or aluminum and can support various pipe sizes.

Adjustable Trapeze Hangers

Adjustable trapeze hangers feature components that can be modified to accommodate different pipe diameters or configurations. This flexibility makes them suitable for dynamic environments where changes are common.

Pre-Insulated Trapeze Hangers

Pre-insulated trapeze hangers are designed for insulated pipes, often seen in HVAC systems. They provide thermal protection and reduce condensation issues by isolating the pipe from its surroundings.

Rigid and Flexible Trapeze Hangers

Rigid trapeze hangers are designed to hold pipes firmly in place, while flexible hangers allow for some movement, accommodating thermal expansion and contraction.

Materials Used in Trapeze Hangers

The materials used to fabricate trapeze hangers significantly influence their performance and longevity.

Steel

Steel is the most common material for trapeze hangers due to its strength and durability. Galvanized steel is often used for added corrosion resistance, making it suitable for outdoor or humid environments.

Aluminum

Aluminum trapeze hangers are lightweight and resistant to corrosion, making them ideal for applications where weight is a concern. However, they are generally less robust than their steel counterparts.

Stainless Steel

Stainless steel hangers provide excellent corrosion resistance and are often used in food processing or chemical applications, where hygiene and durability are paramount.

Composite Materials

Innovative composite materials are emerging in trapeze hanger production, offering a combination of lightweight properties and resistance to corrosion.

Advantages of Trapeze Hangers for Pipe Supporting

Trapeze hangers provide the following advantages while supporting a pipe:

Versatility and Flexibility:

One of the key advantages of trapeze hangers is their versatility. They can be used to support a wide range of pipe sizes and configurations, making them suitable for various applications. Whether you need to support a single pipe or multiple pipes at different elevations, trapeze hangers can be customized to meet your specific requirements. This flexibility saves time and effort during installation and ensures a perfect fit for the project at hand.

Optimal Load Distribution:

Trapeze hangers are designed to evenly distribute the load along the length of the support system. The unique trapeze shape and the use of sturdy materials like steel ensure that the weight of the pipes is evenly distributed, reducing the risk of stress concentrations and potential structural failures. This ensures the long-term integrity of the piping system and minimizes maintenance costs.

Easy Installation:

Compared to other pipe support systems, trapeze hangers offer ease of installation. They typically come pre-fabricated or with detailed installation instructions, making the setup process straightforward for construction crews. This not only saves time but also reduces the likelihood of errors during installation, leading to more efficient and cost-effective project execution.

Enhanced Adjustability:

As construction projects evolve, the need for adjustments in pipe layouts often arises. Trapeze hangers allow for easy and precise adjustments, facilitating modifications without compromising the overall stability of the support system. This feature is particularly useful in scenarios where there are changes in pipe routing or when adding additional pipes to the system.

Corrosion Resistance:

Trapeze hangers are commonly constructed using materials with excellent corrosion resistance properties, such as stainless steel or galvanized steel. This ensures that the supports remain durable and reliable even in harsh environmental conditions or corrosive atmospheres, enhancing the longevity of the entire piping infrastructure.

Cost-Effectiveness:

While trapeze hangers might seem like a premium solution, their cost-effectiveness becomes apparent when considering their long-term benefits. Their durable nature and low maintenance requirements result in reduced life-cycle costs compared to other pipe support systems, making them a financially sound investment for any construction project.

Compliance with Building Codes:

Engineers and architects must adhere to strict building codes and safety standards when designing and constructing pipe support systems. Trapeze hangers are designed and tested to meet these industry regulations, ensuring that the supported pipes are safe, secure, and compliant with the necessary guidelines.

Applications of Trapeze Hangers

Trapeze hangers are utilized in various industries, each with unique requirements.

Plumbing

In plumbing, trapeze hangers support water supply and drainage pipes, ensuring they remain secure and free from damage.

HVAC Systems

Trapeze hangers are commonly used in HVAC installations to support ductwork and piping, maintaining system efficiency and performance.

Industrial Applications

In manufacturing and industrial settings, trapeze hangers support heavy pipes and conduits, contributing to the overall safety of the facility.

Commercial Construction

In commercial buildings, trapeze hangers are crucial for organizing and supporting plumbing, HVAC, and electrical systems.

Residential Construction

In homes, trapeze hangers help support plumbing systems and provide structural integrity in basements and attics.

Considerations When Choosing Trapeze Hangers

The main parameters that must be looked upon while selecting a trapeze hanger for a specific service are:

- Load Capacity: Ensure the trapeze hanger can support the weight of the pipes and any additional loads they may carry.

- Environmental Conditions: Consider the environment where the hangers will be installed. Corrosion-resistant materials may be necessary in humid or chemically aggressive settings.

- Code Compliance: Ensure that the selected trapeze hangers comply with local building codes and regulations.

- Installation Requirements: Consider the complexity of installation. Some trapeze hangers may require specialized knowledge or tools.

Conclusion

In summary, trapeze hangers offer numerous advantages for pipe support in various industrial and commercial applications. Their versatility, optimal load distribution, ease of installation, enhanced adjustability, corrosion resistance, cost-effectiveness, and compliance with building codes make them a superior choice for any project.

As construction practices continue to evolve, trapeze hangers are likely to become an even more integral part of modern pipe support systems, providing engineers and construction professionals with a reliable, efficient, and long-lasting solution to support their piping infrastructure needs.

Trapeze hangers find application in HVAC (heating, ventilation, and air conditioning) systems, plumbing, fire protection, and various industrial piping installations. Their versatility and reliability make them a popular choice for engineers, architects, and construction professionals seeking effective pipe support solutions.

Online Course on Pipe Support Engineering

If you want to learn more details about pipe support engineering then the following online course is a must for you: