What is Underwater Welding?

Underwater welding, as the name properly hints, is the welding inside the water. This is mainly used to repair offshore pipelines and structures, ships, submarines, and nuclear reactors. Joining two metal pieces underwater requires a lot of safety considerations. The purpose of this presentation is for general knowledge only on how “underwater welding” is carried out. Safety is also emphasized here as we are dealing with two types of activities, Diving, and Welding. One must remember that underwater welding is a different world, and so special precautions are adhered to for maximum safety of the welder/diver.

Introduction of Underwater Welding

Underwater welding began during World War 1 when the British Navy used it to make temporary repairs on ships. Those repairs consisted of welding around leaking rivets of ship hulls. Underwater welding was also restricted to salvage operations and emergency repair works only. In addition, it was limited to depths below the surface of not over 30 ft (10 meters).

At first, underwater welding was just applied to weld a patch until a more thorough repair could be performed. But as soon as more experience was gained, ambitious individuals and companies joined forces to improve results and to establish achievable specifications.

Use of Underwater Welding

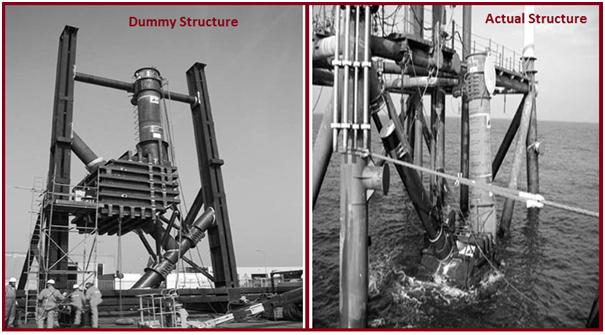

While underwater welding has been used for new construction & installation of offshore structures, subsea pipelines, & harbor facilities, it is most often used for maintenance and repair applications. These include repair of damage caused by corrosion, fatigue, and accidents of offshore structures such as oil platforms, repair & replacement of damaged subsea pipeline sections, repairing holes in ship’s hulls, or collision damage to harbor facilities.

Judging from the photographs shown below (Fig. 1), it is obvious that these structures have to be repaired. And one of the tools of repair is underwater welding.

The Welder

- Welder – is a certified welder who is also a commercial diver, capable of performing tasks associated with commercial subsea work, weld setup and preparation, and who has the ability to weld in accordance with the AWS D3.6, Specification for Underwater Welding (wet or dry), and other related activities.

- Welder qualifications required for a given assignment vary from project to project. Most diving contractors would like their welder/diver to be “a jack of all trades”. This means that the welder/diver must know how to do underwater cutting, fitting and rigging, inspection and nondestructive testing, and underwater photography.

Classification of Underwater Welding

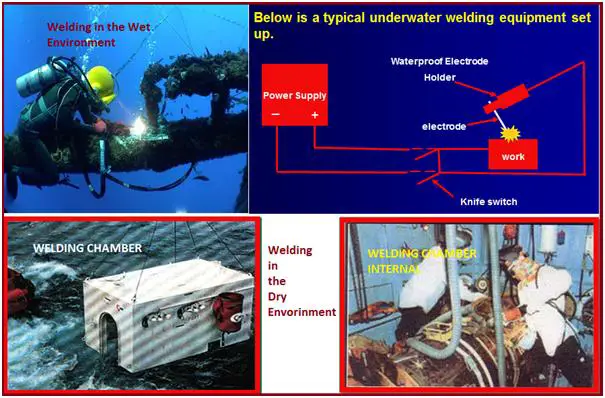

Underwater welding is classified into two categories.

- Welding in the wet environment = this was used primarily for emergency repairs and salvage operations in shallow waters due to poor quality welds.

- Welding in-the-dry environment = this technique produces high-quality welds that meet X-ray and code requirements.

Welding in-the-wet environment

As the name implies, underwater wet welding is done in an environment where the base metal and the arc are surrounded entirely by water. The electrode types used conform to AWS E6013 classification. These electrodes are waterproofed by wrapping them with waterproof tape or by dipping it into special sodium silicate mixes and allowing them to dry. The power source is a direct current machine rated at 300 or 400 amperes.

The power of the arc generates a bubble of a mixture of gasses that lets metal melting and joining occur more or less normal as shown in Fig. 2.

Welding in-the-dry environment

Welding in-the-dry environment is again divided into two:

- Hyperbaric welding, in which a chamber is sealed around the structure to be welded and is filled with breathable gas at the prevailing pressure.

- Cofferdam welding, which is carried out in the dry, air, where a rigid steel structure to house the welders is sealed against the side of the structure to be welded and is open to the atmosphere.

Hyperbaric welding is done with the use of a welding chamber or habitat. This method provides high-quality weld joints that meet radiography and code requirements. The chamber is sealed into a structure or pipeline and filled with a breathable mixture of helium and oxygen (90-95% helium and 5-10% oxygen).

Cofferdam welding is also a type of dry welding where a rigid steel structure to house the welders is sealed against the side of the structure to be welded and is open to the atmosphere. It is normally used for harbor works or ship repair

Photographs in Fig. 3 are examples of Cofferdam Welding

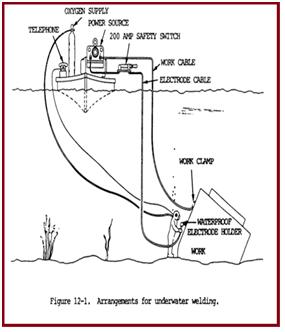

Principle of Operation

The figure (Fig. 4) below right shows the general arrangement for underwater welding. Underwater welding should always be a direct current machine grounded to the ship. The welding circuit includes a knife switch that is operated on the surface by an assistant upon the signal of the welder/diver. The knife switch cuts off the welding current and is designed this way for safety reasons. The electrode holder utilizes a twist-type head for gripping the electrode. The work lead is attached within 3 ft. from the point of welding and is perfectly insulated to avoid leaks. The welding circuit should be direct current electrode negative.

Codes, Standards & Specifications governing Underwater Welding

Underwater welding is covered under the following codes and standards:

- AWS D3.6- Specification for Underwater Welding.

- ASME N-516- Underwater Welding Section XI Div. 1

- BS EN ISO 15618-1:2002- Qualification Testing of welders for underwater welding.

AWS D3.6M 1999 Specification for Underwater Welding

This specification covers the requirements for welding structures or components under the surface of the water. It includes welding in both dry and wet environments. Sections 1 through 6 constitute the general requirements for underwater welding while sections 7 through 10 contain the special requirements applicable to four individual classes of welding:

- Class A – Comparable to above-water welding.

- Class B – For less critical applications.

- Class C – Where load-bearing is not a primary consideration.

- Class O – To meet the requirements of another designated code or

Case N-516-3 Underwater Welding ASME Section XI

Scope and General Requirement –

- Requirements for wet and dry underwater welding.

- Additional variables for dry underwater Welding – Procedure and Performance Qualification.

- Additional variables for wet underwater Welding – Procedure and Performance Qualification.

- Filler metal qualification – Each filler metal is tested in accordance with applicable SFA specifications.

- Alternative procedure qualification requirements – By Charpy V-notch.

- Examination – By NDE.

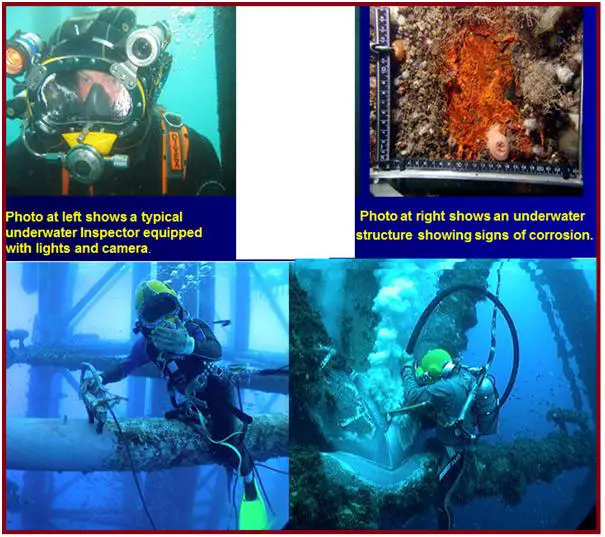

Underwater Inspection

The underwater inspection also includes a visual and photographic examination of underwater structures and repairs, and a Non-Destructive Examination such as the Magnetic Test, Ultrasonic Test, and Radiographic Test.

Non-destructive Testing like UT, RT, and MT can also be done underwater.

The photograph in figure 5 (Fig. 5) shows an underwater NDT technician using Magnetic Particle Testing on underwater structural supports.

Books are also available in the market for reference like;

- Non-destructive Examination of Underwater Welded Steel Structures.

- Underwater Wet Welding and Cutting.

- Underwater Repair Technology.

- Professional Diver’s Manual on wet Welding.

Visual, video, and photographic examination can also be carried out during maintenance inspection on any underwater structures as shown below

In order to carry out a proper visual and NDT check, blast cleaning has to be carried out to remove all seawater organisms that grow on the underwater structure as shown in the photograph in Fig. 5.

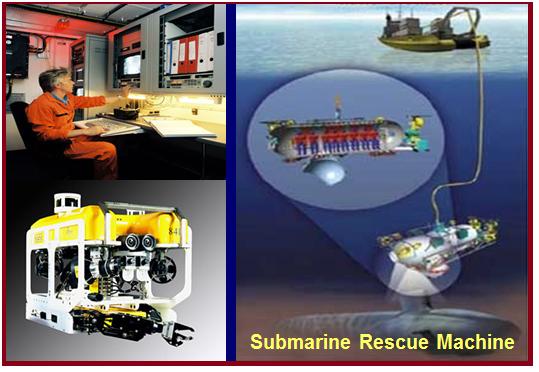

The latest development in underwater inspection is the use of ROV. These are (Fig. 6) machines operated by an ROV pilot.

Risk Involved in underwater welding & inspection

Below are some risks involved in underwater welding:

Electric shock – there is a possibility of electric shock when the equipment is not properly insulated, or when the power supply is not shut off immediately when the welder terminates the arc during welding.

Explosion–arc welding produces hydrogen and oxygen. Pockets of gasses can build up and are potentially explosive.

Nitrogen Narcosis – a health hazard normally experienced by divers during diving activities when safety stops at a certain level is not adhered to. Curiously, the risk of drowning is not listed with the hazards of underwater welding.

For welded structures, an inspection of welds after welding may be more difficult than welds made above water. There is a risk of defects that may remain undetected and may cause failure in the long run.

Safety Standards for underwater welding & inspection

The following safety standard governs the activities for underwater welding and inspection

- OSHA Standard 1915.6 – Commercial Diving

- OSHA Standard 1910.424 – SCUBA Diving

- Volume IV, Issue 3, 3rd Quarter 2002

- Occupational Health Newsletter – Commercial

Safety during Welding

- Necessary precautions should be carried out such as:

- Follow employers’ safety practices.

- Fumes and gasses can be hazardous to your health.

- Arc rays can injure eyes and skin.

- Use adequate ventilation while welding.

- Wear suitable eye protection and protective clothing.

- Do not touch live electrical parts.

- Wear rubber gloves.

- Only change the electrode when cold.

Latest Developments

- With the latest development in the construction of offshore oil platforms, there has been an increased demand for underwater welding. The use of hyperbaric chambers to produce code-quality welds is very expensive to operate.

- Sea Grant Researcher Dr. Chon Tsai has developed a new welding electrode for wet welding nicknamed “Black Beauty” for the black appearance of its waterproof coating. The electrode exhibits excellent visual appearance and profile, micro-cracking of weld has been eliminated, operating characteristics are superior to other commercially available electrodes, and the electrode produces suitable results when used in any position.

Wet-Dry welding

Dry hyperbaric chambers or habitats are extremely expensive. This is because it must be built for special applications such as repairing or making tie-ins on horizontally laid pipes. Recent improvements allowed GMAW (Gas Metal Arc Welding) process to be used in underwater welding with the use of special nozzles, domes, or miniature chambers. In using this type of apparatus the welder/diver is in the water but the nozzle of the welding gun and material to be welded is in the dry atmosphere. These localized dry gas environment chambers are inexpensive, small, and lightweight. It is made of transparent material or has a sufficient number of windows so that the welder can see the inside to properly manipulate and direct the welding gun. This process can be utilized for welding up to 125 ft. (35m) below the water surface.

Few more welding articles for you.

Welding Galvanized Steel

Overview of Pipeline Welding

Welding Positions: Pipe Welding Positions

Welding Defects: Defects in Welding: Types of Welding Defects

Welding Inspector: CSWIP and AWS-CWI

General requirements for Field Welding

Underwater Welding & Inspection Overview

Methods for Welding Stainless Steel

References

- https://www.sciencedirect.com/topics/engineering/underwater-inspection

- https://www.sciencedirect.com/topics/engineering/underwater-welding

Video Courses in Welding

To learn more about welding the following video courses you can refer to: