A Vacuum Breaker is a device that helps the air to fill the vacuum created inside a steam piping system. As the name suggests, the vacuum breaker breaks the unwanted vacuum inside a closed system. There are many instances when a vacuum can be created inside a steam piping system, for example during steam condensation. If the piping system is not designed properly (piping thicknesses need to be checked for vacuum pressure condition) to take care of that vacuum situation, it may lead to a sudden collapse of the piping system.

In such a situation, Vacuum breakers play an important role to safeguard the piping system by allowing air to fill the vacuum. Vacuum breakers help in protection against freezing and water hammer and allow gravity drainage in condensing equipment under modulated control.

Use of Vacuum Breaker

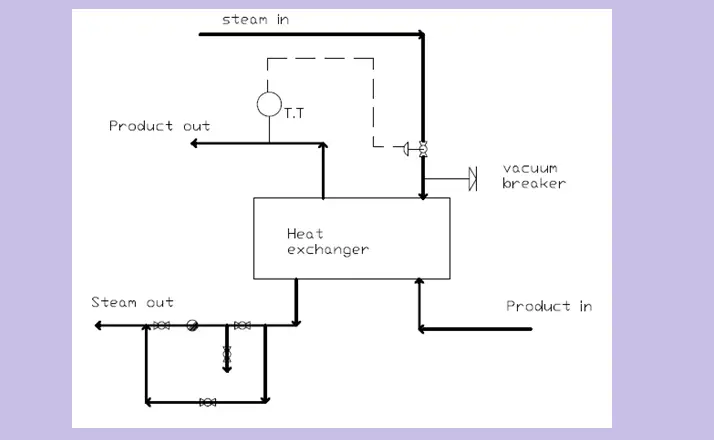

The proper use and the reason for having a vacuum breaker in a steam system are illustrated with an example as follows:

Assume the way this is piped is:

We’ve got boiler pressure steam at 10 psi or a little more. Then a control valve, from here it’s piped into the top of a heat exchanger.

We’ve got a condensate line that comes down to a steam trap. Then it goes to a check valve and from there it goes to our atmospheric condensate return system. So if we’ve got the control valve wide open, we’ve got a little bit of differential pressure across the control valve and the heat exchanger. But we’ll see that there is still plenty of differential pressure down here to push the condensate through the primary trap and everything works just fine as the product inside the heat exchange starts to warm up, of course, our control valve is going to modulate down so you can see our pressure starts to drop off.

Also, the pressure will drop off at the condensate line as well. Problems will arise if the condensate pressure is not enough to drive the condensate through the steam trap, or if there is further modulation in the control valve which can lead to backflow to the heat exchanger itself, or even worse, it can create a vacuum pressure.

That either leads to temperature control issues downstream or we can have a water hammer or we can have the potential for freezing or the long term will corrode our system so the solution to the issue is a vacuum breaker.

Now if we have a vacuum breaker installed right before the heat exchanger when this valve is opened, you’ll hear atmospheric pressure air entering that breaker and you can watch the gauge go from vacuum pressure up to zero so now we’ve got zero psi in our system.

No matter if we have positive pressure or we if we go all the way down to zero, we can never get below zero. Now if we mount our trap 14 or 18 inches below our heat exchanger we can always make sure that we generate positive pressure proper installation of a vacuum breaker will ensure that we have positive drainage.

What does a vacuum breaker do?

So to sum up the advantages, here are the top 4 reasons for including a vacuum breaker in your system:

- It helps allow for complete condensate drainage under all operating conditions: on/off or modulating applications.

- It protects against a water hammer.

- It helps reduce temperature fluctuations and uneven temperatures.

- It helps to reduce product waste.

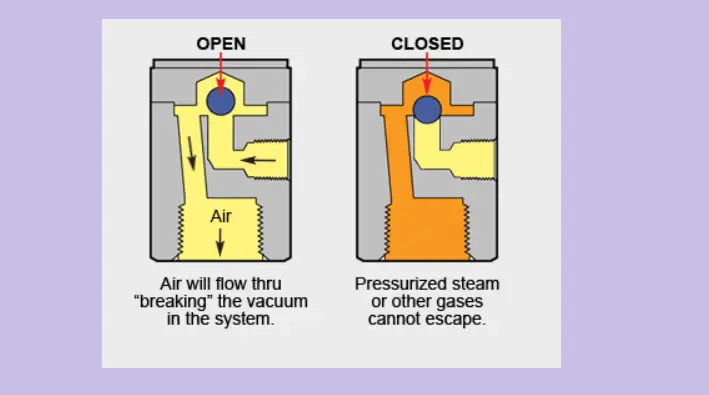

How does a steam vacuum breaker work?

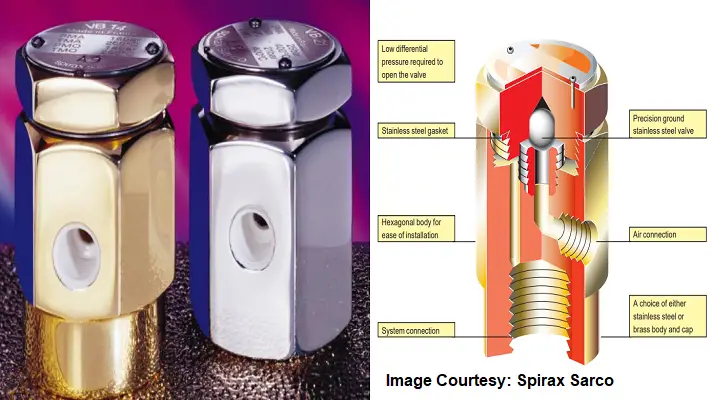

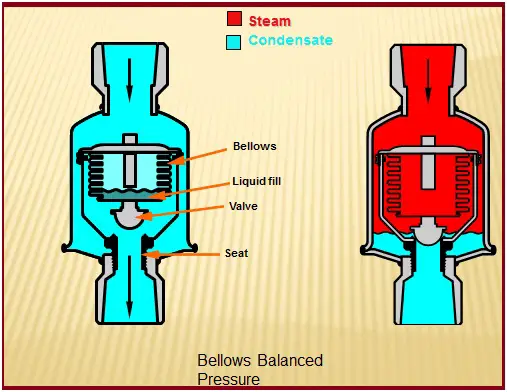

The Vacuum Breaker functions like a simple check valve. Outside air is allowed to enter the system through the air inlet. However, when steam or water tries to escape, the vacuum breaker closes off tightly.

Vacuum Breaker Installation

The unit must be installed in a vertical position and should be placed at the highest point in the system. Fig. 3 shows a typical vacuum breaker that can be used in steam piping systems.