What is Flow-Induced Vibration or FIV?

Flow-Induced Vibration or FIV is a large amplitude, low frequency (generally <100 Hz) vibration that can occur in piping systems carrying high-velocity turbulent fluids. Flow-induced Vibration i.e, the fluid flow generates high kinetic energy that forces the piping system to vibrate (Piping Vibration is induced in the system by Fluid flow). It is more prevalent near turbulent sources such as pipe bends, reducers, branch connections (Tee connections), partially closed valves, process equipment connections, etc.

Flow-Induced Vibration in Pipes

In recent days, risk due to flow-induced vibration has increased a lot due to

- Increased flow rate (high velocity) that results in a high level of turbulent energy

- Use of thin-walled piping i.e high D/t ratio

- Long pipe support span which results in flexible piping

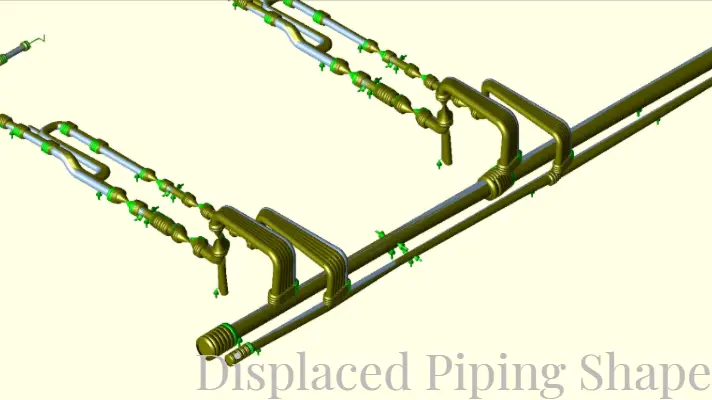

Effect of Flow-Induced Vibration

Flow-Induced vibration displaces the piping system in the longitudinal and transverse direction and in some cases leads to damage to the pipe supports.

Considering the momentum flux (density X velocity2), High-density Liquids are more prone to Flow-Induced Vibration as compared to gases.

Flow-Induced Vibration Analysis

DEP 31.38.01.26 (Design and Engineering Practice by Shell Global Solutions International) provides detailed steps for screening piping systems for Flow-Induced Vibration (FIV) by calculating momentum flux (density X velocity2) and categorizes failure susceptibility into three groups:

- Negligible,

- Medium and

- High.

They also suggest further steps to follow when the susceptibility falls into the Medium or High Category. For High category vibration susceptibility fluids, the Likelihood Of Failure (LOF) needs to be calculated following detailed steps mentioned in Energy Institute guidelines for the avoidance of vibration-induced fatigue failure in process pipework. The aim of the piping engineer will be to keep LOF below 0.3. However, if LOF is more than 0.3 then corrective actions need to be taken to mitigate the vibration possibility.

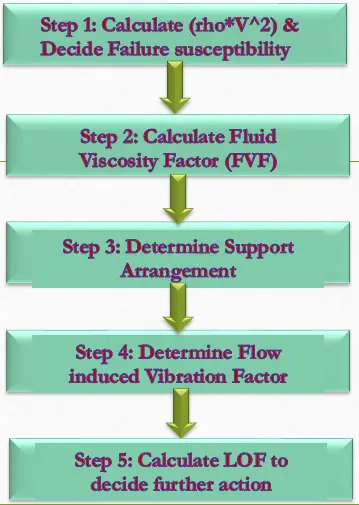

Flow-Induced Vibration Steps

The steps for detailed flow-induced vibration analysis based on the Energy Institute Guidelines (Use this guide for equations) are provided in the image below:

Mitigation of Flow-Induced Vibration

Flow-Induced Vibration or FIV normally takes a long time to cause metallic fatigue failure. Hence, it is usually resolved when vibration is observed physically after commissioning the plant. The most common mitigation is to add supports or restraints. By adding the appropriate guide and line stop supports, i.e by increasing system rigidity, the damaging effect of FIV can be reduced a lot. These added supports will minimize the shaking tendency of the pipe, thus reducing the tendency of pipe failure. Other mitigations against Flow-Induced Vibration in Piping Systems could be

- Reduce fluid velocity by increasing pipe size or by changing process conditions.

- Increase system rigidity by increasing pipe wall thickness.

- Install viscous damper, shock arrestor, snubber, etc in the piping system

- Reduce the number of turbulent sources like elbows, reducers, etc.

- Tighten the clearances in between pipes and supports.

- Stress concentration at branches can be reduced by contoured pipe fittings and gussets on Smallbore connections

Few more related Resources for you.

What is Acoustic-Induced Vibration or AIV?

What is Flow-Induced Vibration (FIV) in a Piping System

Basics of Vibration Monitoring: A Presentation

Common Causes and Effects of Piping Vibration

Solving vibration problems in a two-phase flowline by Dynaflow Research Group

Considerable points while installing centrifugal pumps at the site to reduce vibration

Online Course on Flow-Induced Piping Vibration Study

To learn more about flow-induced piping vibration study, I recommend the following online video course:

- Flow-Induced Vibrations for Piping Systems: FIV or Flow-Induced Vibration is a serious problem that has the potential to cause pipework and support failure thus impacting the structural integrity of the piping system. So, FIV study has become more important in recent times and many organizations made it mandatory to perform FIV assessment during the detailed design phase. In this course, You will learn the basic theory of Flow-induced vibration, Steps for FIV Analysis, and Finally some mitigative options.

References and Further Study

- DEP 31.38.01.26 V43

- Energy Institute guidelines for the avoidance of vibration-induced fatigue failure in process pipework

- https://www.bechtel.com/getattachment/Blog/technical/October-2019/Differentiating-Between-Acoustic-and-Flow-Induced/Differentiating-Between-Acoustic-and-Flow-Vibrations.pdf

Hellow Mr DEY please send your contacts details in my mail chatterjeedibyendu50@gmail.com. Thanks

Is AIV/FIV study applicable on vent / drain lines in a piping system?